Avoiding Common Gearbox Lubrication Problems

By Greg Cober, Boston Gear

By Greg Cober, Boston Gear

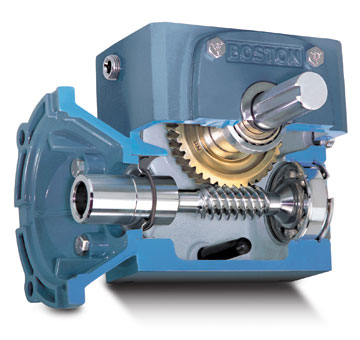

The right-angle worm gearbox is a simple device that is used widely in manufacturing facilities. Like nearly all gears, enclosed worm gear drives require proper lubrication in the appropriate amounts. It is these two factors — lack of lubrication and the use of incorrect lubrication — that are the most common causes of premature failures in worm gearboxes.

Lack of Lubrication

Operating a worm gearbox dry (without lubrication) frequently leads to failure of the unit. Manufacturers often ship gearboxes dry for a couple of reasons. First, the added weight of the lubricant adds to shipping costs, and that weight can be significant in larger gearboxes. Secondly, numerous manufacturing facilities have standardized on a specific lubrication supplier, and while many lubricants are interchangeable, they should not be mixed. Shipping a unit dry allows the end users to ensure commonality within their facility.

Unfortunately, a novice installer may ignore or neglect to read the tags, labels and installation manual warnings that indicate there is no lubrication and start up a drive-train with a gearbox that is without lubrication. Running a unit dry will rapidly cause damage to the bronze worm gear. Even if lubrication is added after the fact, this damage is permanent, and the gearbox will need to be replaced or rebuilt. There is no way to “heal” a damaged gear.

Not Enough Lubricant

A related failure occurs when there is too little lubrication. This can often be the result of the gearbox mounting. The most common mounting for a worm gearbox is referred to as “worm over,” which means the worm rests above the bronze gear. In worm-over orientation, a gearbox needs a set level of lubricant. However, this same gearbox assembly can be mounted in the worm-under orientation, which requires additional lubrication.

A related failure occurs when there is too little lubrication. This can often be the result of the gearbox mounting. The most common mounting for a worm gearbox is referred to as “worm over,” which means the worm rests above the bronze gear. In worm-over orientation, a gearbox needs a set level of lubricant. However, this same gearbox assembly can be mounted in the worm-under orientation, which requires additional lubrication.

The gearbox construction and the manner in which lubrication moves with the gears can be such that a unit with worm-under mounting may require as much as 50 percent more lubrication than a unit with worm-over mounting. Failure to increase the amount of lubrication will mean that the bearings on the output shaft will run dry and fail in a relatively short period of time.

For any given gearbox, there is no physical reason a unit may not be mounted in the worm-over or worm under orientation so long as proper lubrication levels are maintained. One of the problems that results from insufficient lubrication is that failure is not immediate. The unit will perform well for a time, perhaps a few weeks or a month, depending upon the application. As a result, a technician may not make the connection between too little lubricant and the unit failure, and may repeat the error.

Determining how much lubrication is required for a gearbox in a specific mounting orientation is relatively easy. Gearbox manufacturers provide this information in their catalogs, manuals and online. There should also be application support staff available by phone as well as field sales staff who can provide guidance.

Improper Lubricant

A second common cause of failure in gearboxes is the use of inappropriate lubrication. Gearbox manufacturers have identified and tested specific lubricants for use in their products. Whenever possible, it is best to follow these recommendations. The selections they have made are based upon the goal of providing the best possible unit life for the customer. Like lubrication amounts, this information is readily available in catalogs, manuals, online or via phone support.

A second common cause of failure in gearboxes is the use of inappropriate lubrication. Gearbox manufacturers have identified and tested specific lubricants for use in their products. Whenever possible, it is best to follow these recommendations. The selections they have made are based upon the goal of providing the best possible unit life for the customer. Like lubrication amounts, this information is readily available in catalogs, manuals, online or via phone support.

Beyond having the “best” lubricant for a given gearbox, there are specific lubricant characteristics that are known to damage gears. In worm gearboxes, typically the worm is made of steel and the gear of bronze. Lubricants that include extreme-pressure (EP) additives of sulfur or chlorine will sometimes soften the bronze gear surface, with the result being a reduction in unit life.

Many lubricants that are classified as EP will include these chemicals. While it may seem intuitive that an EP lubricant will be appropriate for gearing, in this case it is actually the opposite, as EP additives will accelerate wear on the bronze gear by softening the gear teeth. In conclusion, since right-angle worm gearboxes are common tools for reducing speed and/or magnifying torque in a wide array of applications, it is important to verify that they are lubricated with the proper type and amount of lubrication. By taking these simple but critical steps, a maintenance staff can help ensure the longest life from their installed gearboxes.

These bronze gear shavings resulted from a gearbox that was run dry.

A gearbox mounted in the worm-under orientation requires additional lubrication.

These bronze gear teeth have been worn smooth after prolonged exposure to a lubricant with EP additives.