Implementing a Best-Practice Lubrication Program

A well-designed and properly executed lubrication program can provide significant fiscal opportunities for your plant. When developing lubrication programs for its clients, Noria uses a phased approach. The first phase is a benchmark assessment. During this phase, an engineering consultant travels to the plant and assesses the current state of the program. This helps identify deviations from best practice in the core areas of the client’s lubrication program. At the end of this phase, clients not only should have a clear understanding of the steps necessary to transform their site but also an idea of the priority level of each of the changes to be made.

The second phase is to design the Optimum Reference State (ORS) for each individual lubrication point. This includes developing procedures and job plans that consist of equipment hardware modifications, inspections, oil analysis, preventive maintenance (PM) and on-condition-based tasks that all relate to improving the asset’s maintainability and reliability.

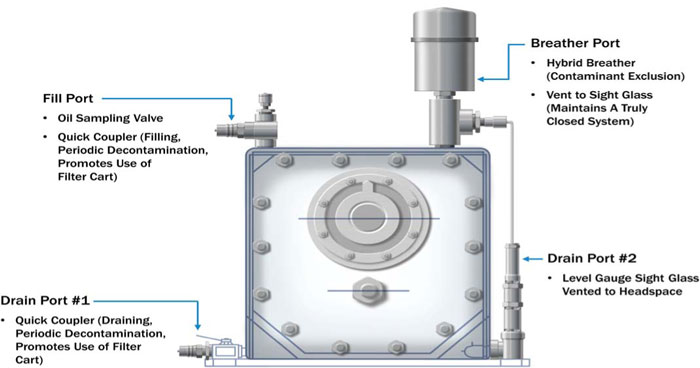

The third phase, which will be the focus of this article, is the implementation of the design. Modifying your equipment is the first step in this phase. If you truly want to make strides toward becoming a world-class program, you will need to make equipment modifications. These generally are non-invasive modifications that serve a specific purpose. Figure 1 shows several examples of these modifications.

By adding accessories such as desiccating breathers, quick-connects, external level gauges and sample ports, you can transform a small gearbox to world-class standards in terms of contamination control, maintainability and reliability. Without the addition of items like an oil sample valve with a pitot tube, there would be no way to pull an oil sample as recommended by the design during the second phase. This is why clients are advised to purchase and install all accessories first. Without certain accessories in place, recommendations like pulling an oil sample or inspecting a level gauge will not make sense.

What to Buy

Many decisions will need to be made at this point. There are numerous manufacturers and resellers of products aimed specifically at this market. Your decisions should be based on what it will take to accomplish your reliability goals. Be sure to always consider a product’s life-cycle cost and its effect on your ability to achieve your goals. The old saying, “You get what you pay for,” is true with machine modification accessories. It seems there is always a tradeoff between upfront costs vs. life-cycle costs. I’m a big fan of spending a little extra upfront to get the highest quality while reducing the life-cycle cost in the long run. However, buying cheaper quality with a lower upfront cost and a higher life-cycle cost has also worked well for some clients. Either way, the machine and components will benefit from the added attention, and that is the ultimate goal.

4 Steps to Lubrication Excellence

Step 1: Benchmark Performance - Define the scope and criteria, set goals and priorities, and benchmark current performance to best practice.

Step 2: Define Opportunities -These opportunities may relate to PM scope optimization, failure prevention, failure severity minimization, work planning and energy efficiency.

Step 3: Design Best Practice - Create the blueprint for oil analysis inspection, lubricant selection, lubrication procedures, contamination control, training and skills management, and metrics.

Step 4: Implement Best Practice - Ensure awareness and communication to stakeholders, equipment modifications, auditing/testing, and continuous improvement.

Most vendors are more than happy to showcase their products for the chance at earning your business, so ask for samples and try out each product. See what you like and what you don’t. In some cases, you may be spending hundreds of thousands of dollars on these items, so you really should ensure they will work for you.

Installation

This final step can begin only after you have made the decisions on what to buy and everything is sitting on the dock ready to be installed. Installation may need to be timed with a shutdown, or it may be able to be completed on the run. Regardless, the timing is important but not as important as who will be making the modifications. Typically, the most successful method is to have an elite team of installers whose sole purpose is the widespread installation of the modifications. Each team member must be trained on the products and how they should be installed. The team should not have other duties during this time. They must be focused on the task of modifying the equipment for the Optimum Reference State.

After overcoming this hurdle, which can be quite formidable for many companies, the only remaining task is to follow the designed best practices in terms of oil sampling, inspecting, reacting to any changes, performing PMs on schedule, etc. Of course, if you have any questions about designing or implementing a best-practices lubrication program, please contact Noria Corporation.