How to Change Your Lubrication Culture

In many of the training courses Noria provides, we discuss how a culture change is required in most cases to achieve a world-class lubrication program. This is by far the most difficult part of the process. The assessment is easy. A technical consultant walks through your plant or facility and looks for opportunities. Most often the low-hanging fruit is obvious and simply overlooked by plant personnel because it has become part of the standard scenery. With a fresh set of eyes specifically looking for these opportunities, they are generally not too difficult to find.

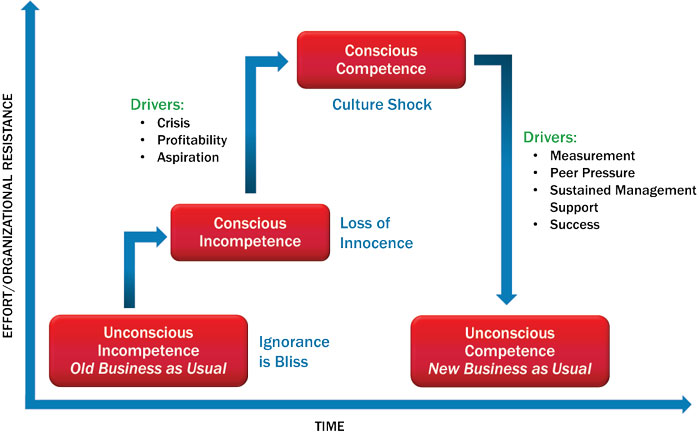

Frequently, the facilities being assessed are operating in an “unconscious incompetence” stage, as shown in the diagram below. This simply means that the workforce is doing the wrong things and isn’t even aware that they are wrong. After training or an assessment is conducted, the facility moves to the second stage. Personnel at the plant are no longer ignorant of the right way to do business. Eyes have been opened, and innocence has been lost. Now they can pursue the optimum reference state (ORS) of lubrication excellence.

This is where things get difficult. Knowing the right things to do and actually doing them are obviously not the same thing. This is known as the knowing-doing gap. So now that you know what is right and wrong, how do you get that “culture shock” to take place?

During my career in the U.S. Navy, I was told repeatedly that an organization takes on the traits of its leadership. In other words, what the boss wants, generally the boss gets. If it is important to the boss, it is going to be important to the rest of the organization as well. Therefore, the easiest way to achieve a culture change is to get the boss onboard. Sometimes it is not always easy. You may have to be the champion of change and fight in the trenches alone. The following tips can help you affect the change you are seeking.

First, use the Pareto principle or the 80/20 rule. You may have been taught the 80/20 rule in terms of 20 percent of the workers do 80 percent of the work, but at Noria we apply it to contamination. Twenty percent of the causes of failure are responsible for 80 percent of the occurrences of failure. By and large the greatest percentage of damage to equipment is due to particulate contamination. So if particles are the largest source of contamination, this prioritizes how you should invest your time and efforts.

Particles can get into machines in a few ways. They may be built in, ingressed or generated. The cost of excluding contaminants is less than 10 percent of what it will cost you once they are allowed to ingress into your fluid (see Justifying cost of excluding a gram of dirt). If you want to get your boss onboard, you will need to put this in terms of cost savings. There are several case studies that show the cost benefits of filtration, breathers, keeping shaft seals in good shape, etc. These studies address the savings in lubricants, bearings, downtime and many other areas that you can use to form a sound argument.

Secondly, you must get other team members onboard. In my experience, explaining the “why” is the most effective method to accomplish this. Why are we doing this? Talking about saving the organization money may or may not be your best approach. Detailing the benefits of keeping the oil clean, cool and dry in terms of reduced downtime and workload may help.

I recently conducted a training course where one of the students was skeptical of the advantages of oil analysis. He was a fan of vibration analysis and thermography but questioned the benefits of oil analysis. I explained that in order for vibration and thermography technologies to be used, you must either have vibration or a higher than normal temperature condition. On the other hand, with a good oil analysis program, you can detect potential issues before they get to the point of registering on either vibration or thermography equipment. The ideal situation is to match all of these technologies. After taking the time to explain the “why” of oil analysis, he began to come around and see the benefits.

This leads us from the “conscious incompetence” stage to the “conscious competence” stage. Now you know the proper procedures, quantities, frequencies, etc., and are putting this information to use. This is when the magic happens and the organization begins to change. You as the champion have made an impression, and the staff is following your example. When you start seeing evidence of this transformation taking place, you should take a moment to congratulate yourself and your team. Many organizations don’t make it this far.

Keep striving to make improvements and eventually you will reach the fourth and final stage, “unconscious competence.” In this stage, personnel perform procedures correctly and aren’t even sure why. When asked why things are done a certain way, they might answer, “I don’t know; we’ve always done it that way.” Better yet, perhaps they can explain why everything is done the way it is. If so, you are well on your way to having a world-class lubrication program. Take the next step. Learn how Noria can help transform your lubrication program.