Babbitt: The Other Bearing Lubrication

| Parameter | Type 2 | Type 3 |

|---|---|---|

| Tin | 89% | 84% |

| Antimony | 7.5% | 8% |

| Copper | 3.5% | 8% |

| Liquidus Point | 669°F | 792°F |

| Brinell Hardness | 24 | 27 |

| Tensile Strength | 12,600 psi at 68°F | 10,000 psi at 68°F |

| % Strength at 212°F | 52 | 52 |

By Mark A. Tarbet, Luminant Power

Journal bearings play a critical role in equipment with large and high-speed rotating components. They primarily are used in machines with more than 500 horsepower and that operate at speeds of more than 3,000 revolutions per minute (rpm). Previously, their most important job was to reduce friction between two surfaces in relative motion. Now, journal bearings not only reduce friction but also provide the means to remove heat and debris while offering protection to more expensive components such as shafts and rotors.

Most journal bearings found in modern industrial equipment are built with a surface of Babbitt material. This material has a smooth, slick surface that is easily wetted by liquids. The soft material is resistant to galling but easily wears away, protecting the harder surface of the typically steel shaft. The bearing surface is sacrificed, with Babbitt actually becoming the lubricant, and the shaft surface is preserved in case there is a loss of lubrication or other operating anomaly.

In the 17th century, Robert Hooke began utilizing “bell” metal as a bearing surface material. Bells were often formed with a bronze alloy that usually included a 4-to-1 mix of copper and tin. In 1839, Isaac Babbitt patented a bearing alloy similar to the material used today. These alloy formulations became so popular that the name “Babbitt” has become synonymous with the material.

The standard Babbitt alloy is comprised primarily of a solid matrix of tin with various amounts of antimony cuboids and/or copper threads. Table 1 shows some of the physical properties of the most common forms of Babbitt classifications in industry.

Although tin enters the liquid phase near 450 degrees F, the liquid phase for the Babbitt alloy microstructure does not occur until temperatures exceed 600 degrees F. This allows for machine operation at higher temperatures, which often result from heavier loads and faster speeds. Journal bearings are quite strong and can carry heavy loads as long as they are lubricated properly. The lubrication forms a protective barrier between the shaft and Babbitt surface while also removing friction-generated heat and debris from the bearing.

Theoretically, a journal bearing may have an infinite life since there is no contact between the bearing surface and journal. This lubrication barrier also provides damping characteristics when passing through rotor-critical speeds, allowing for stable equipment operation. A journal bearing is easier to remove and repair given the split design. It typically produces less noise than anti-friction bearings and has natural electrical isolation properties.

Theoretically, a journal bearing may have an infinite life since there is no contact between the bearing surface and journal. This lubrication barrier also provides damping characteristics when passing through rotor-critical speeds, allowing for stable equipment operation. A journal bearing is easier to remove and repair given the split design. It typically produces less noise than anti-friction bearings and has natural electrical isolation properties.

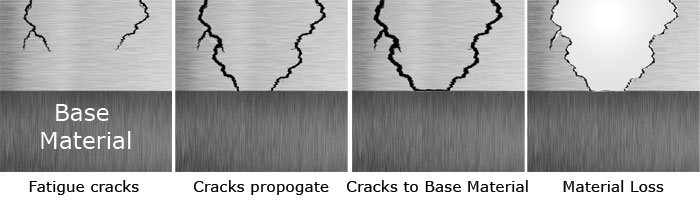

One of the main issues with journal bearings is the requirement of continuous lubrication that is clean and cooled. Contamination is a primary contributor to many bearing failures in industry. The soft characteristics of the Babbitt material make it susceptible to damage during installation. This also means the Babbitt can be easily destroyed if subjected to significant dynamic loading for long periods of time. The Babbitt will eventually crack and break off, leaving voids, as shown in Figure 2.

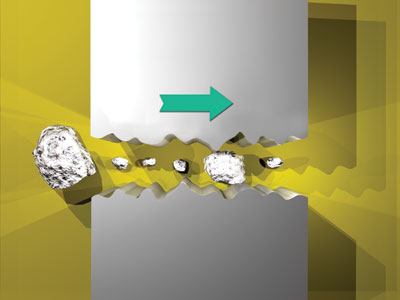

Another common cause of bearing failures is the machine operating at slow speeds either during startup or shutdown. For a bearing to work properly, the shaft surface must be moving at a sufficient speed to draw in the cool lubricant, pressurize it to form a hydrodynamic layer and expel it with any debris formed during the process. Figure 1 illustrates how hard particles can lead to bearing damage. This can occur with small particles at slow roll when the shaft and bearing surfaces are close together or with larger particles during normal operation. Figure 3 shows a journal bearing that was damaged during shutdown as the speed slowed to less than 200 rpm.

Another common cause of bearing failures is the machine operating at slow speeds either during startup or shutdown. For a bearing to work properly, the shaft surface must be moving at a sufficient speed to draw in the cool lubricant, pressurize it to form a hydrodynamic layer and expel it with any debris formed during the process. Figure 1 illustrates how hard particles can lead to bearing damage. This can occur with small particles at slow roll when the shaft and bearing surfaces are close together or with larger particles during normal operation. Figure 3 shows a journal bearing that was damaged during shutdown as the speed slowed to less than 200 rpm.

For Babbitt to work properly, a small portion of the tin is expected to melt and be washed away by the lubricant. This creates channels around the harder particles of antimony and copper, which actually support the shaft and carry the load. These channels allow oil to pass through them, cooling the surfaces and washing away any debris that was formed during normal operation.

Case Study #1: Steam-turbine-driven Boiler Feed Pump

Case Study #1: Steam-turbine-driven Boiler Feed Pump

A large pump experienced a bearing failure during normal operation. The shaft journal was 5.75 inches, and the typical bearing clearance was 7 to 9 mils. A post-mortem test was conducted to determine the possible cause of the failure. Figure 4 shows the bearing when it was removed from the pump. The bearing suffered from significant loss of overlay material, as seen in Figure 5.

Melting along the edges of the overlay material can be seen in Figure 6. This likely was due to significant heating, although there was no thermal data indicating an event had occurred. This picture also shows the redeposition of melted material on the bearing surface.

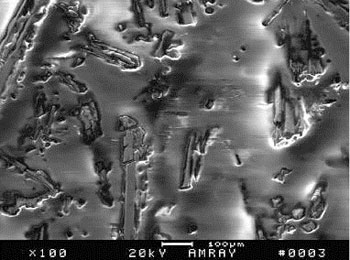

A highly magnified image of the bearing surface (Figure 7) from a scanning electron microscope (SEM) shows the surface microstructure of the Babbitt alloy. It includes copper needles and antimony cuboids embedded in the tin alloy. The shaft surface actually rides on the harder needles and cuboids, while the lubrication flows around them in channels within the tin. This allows for cooling of the bearing surface and the removal of any debris that might enter the bearing.

A highly magnified image of the bearing surface (Figure 7) from a scanning electron microscope (SEM) shows the surface microstructure of the Babbitt alloy. It includes copper needles and antimony cuboids embedded in the tin alloy. The shaft surface actually rides on the harder needles and cuboids, while the lubrication flows around them in channels within the tin. This allows for cooling of the bearing surface and the removal of any debris that might enter the bearing.

Plant personnel believed electrical arcing was the root cause of failure. The study results found no evidence of electrical arcing but pointed toward overheating (likely from a loss of lubrication) as the primary cause. Since the bearing was severely damaged, an accurate diagnosis was difficult. This allowed for the possibility of a simple failure in the bond between the base metal and the Babbitt material as the root cause.

Case Study #2: Fan Bearing Failure

Case Study #2: Fan Bearing Failure

A large centrifugal fan (shown in Figure 8) was operating normally when the bearing metal temperature spiked to 212 degrees F. This was captured by the instrumentation and monitoring systems, initiating a critical alarm condition.

Checks of the fan indicated that the bearing metal temperature spike occurred after a general upward trend in temperature beginning almost five days before the failure. The temperature spike resulted in a sudden increase in vibration and elevated bearing temperatures on both ends of the fan. The lubricating oil level in the system reservoir had also dropped to very low levels.

Figure 9 shows the lubrication cooling pump used to move oil through a radiator attached to the fan inlet. A seal on the pump had failed, and oil was leaking out during operation. The location of the pump caused the leaking oil to be sucked into the fan. Therefore, routine visual inspections by operating personnel did not detect a pool forming. This allowed the oil reservoir level to drop at a steady rate with no visual cues of a problem.

The failure occurred during an operating period with record cold temperatures. The unit needed to be available for full-load operation and had to run regardless of the suspected bearing condition. In order to accomplish this, the reservoir was refilled with new oil. Lube oil filtration carts were placed directly on both bearing drains and monitored continuously.

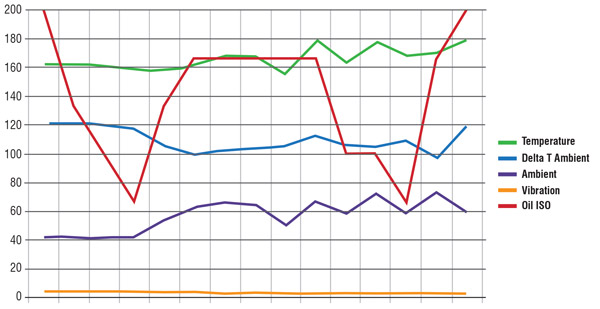

To determine if the bearing condition was stable or deteriorating, lube oil contamination parameters were monitored and tracked regularly, as shown in Figure 12. This allowed the unit to operate until after the severe weather had passed.

To determine if the bearing condition was stable or deteriorating, lube oil contamination parameters were monitored and tracked regularly, as shown in Figure 12. This allowed the unit to operate until after the severe weather had passed.

Once the unit was taken down for repair and the top half of the bearing removed, the damage was evident, as seen in Figure 11. The Babbitt material worked as designed, melting in the absence of lubrication to protect the shaft. After oil was restored to the bearing, the Babbitt cooled and reformed, enabling the machine to continue to operate until an outage could be scheduled. The bearings were replaced during a brief scheduled outage, and the machine returned to normal operation.

References

Leader, M. “Understanding Journal Bearings”

Wikipedia Contributors. “Babbitt (metal).” Wikipedia, The Free Encyclopedia. http://en.wikipedia.org/wiki/Babbitt_(metal)