The Importance of Integrating Knowledge Management with Maintenance

By Victor D. Manriquez, IPEMAN

Many organizations manually collect and store data relating to equipment inspections and repairs. This data is frequently stored in the most accessible place for maintenance personnel - their personal notebooks. These “little black books” contain large volumes of maintenance experience that unfortunately will disappear when the employee retires.

Many organizations manually collect and store data relating to equipment inspections and repairs. This data is frequently stored in the most accessible place for maintenance personnel - their personal notebooks. These “little black books” contain large volumes of maintenance experience that unfortunately will disappear when the employee retires.

In 2006, a study published by the Hudson Institute on the U.S. workforce found that 30 to 40 percent of maintenance personnel would be retiring in the next five years. Considering it is now 2014 and three years beyond the year projected in the study, the scarcity of maintenance employees has become a reality.

The retiring workforce is exerting a pressure that most organizations have never had to face. A high percentage of these professionals have 20 to 30 years of experience, and little has been done to document what they know, what they do and how they do it. As businesses continue to make their operations “lean,” some of these retired maintenance personnel are not being replaced. Even if organizations could afford to replace them, it is becoming hard to find suitable replacements.

Compounding this problem is the fact that fewer people are entering into the maintenance field. There are several reasons for this trend, but they all lead to the same conclusion - more must be accomplished with fewer resources. To achieve this goal, organizations need to integrate knowledge management with maintenance.

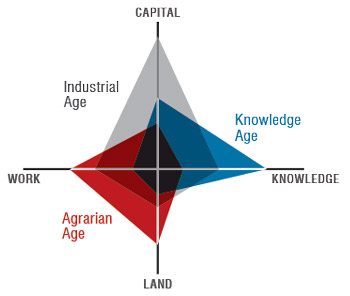

The Knowledge Age

In our contemporary economy, knowledge is a crucial resource because it is inexhaustible and can be used by many organizations and people to generate even more knowledge. We live in the knowledge age, and individuals and organizations who can adapt to the inevitable changes are the ones who will be able to face the future challenges. Those who don’t will be part of the past.

Three criteria must be met before information can be considered knowledge:

- Knowledge is connected. It exists in a collection of multiple experiences and perspectives.

- Knowledge is an action. Information that does not precipitate some type of action is not knowledge.

- Knowledge is applicable in new and unique situations. Information becomes knowledge when it is used to address circumstances for which no direct precedent exists.

Knowledge Management

What does the term “knowledge management” (KM) mean? Typically, three concepts are combined: intellectual capital, which consists of a company’s know-how, patents and trademarks; organizational culture, which includes the willingness to share knowledge and cooperative work within an organization; and information technology, which involves implementing devices that make it easier to access the knowledge produced inside an organization.

What does the term “knowledge management” (KM) mean? Typically, three concepts are combined: intellectual capital, which consists of a company’s know-how, patents and trademarks; organizational culture, which includes the willingness to share knowledge and cooperative work within an organization; and information technology, which involves implementing devices that make it easier to access the knowledge produced inside an organization.

In addition to knowing what KM is, it is also important to understand what it is not. KM is not technology. It is not a directive, and it is not a business strategy. KM is a dynamic management system for a viable business strategy, not just a storage capacity for accumulated knowledge. KM is also the ability to act on that knowledge. Organizations are no longer valued just for what they have done but for the potential of what they might be able to do.

Remember, knowledge is connected. For information to be transformed into knowledge, you must recognize, support and manage the connections, and most importantly the people, who are the ultimate owners of all knowledge.

KM Concepts

KM Concepts

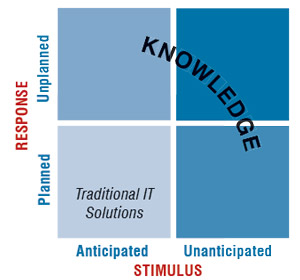

Understanding KM begins with two basic characteristics: knowledge complexity and knowledge applications. The former refers to the physical manifestations and depth of knowledge available, while the latter is the approach to connecting knowledge to people and processes.

Knowledge Complexity

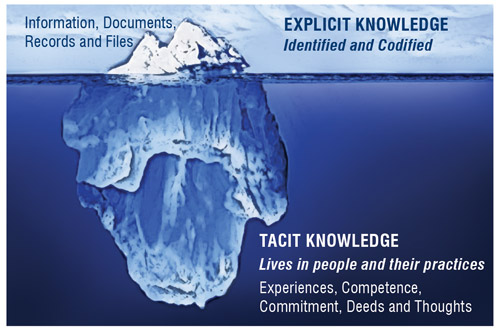

All knowledge can be classified according to its complexity in a continuum from explicit to tacit. Explicit knowledge is articulated in formal language and easily transmitted among individuals. Tacit knowledge is personal knowledge embedded in individual experiences and involving such intangible factors as personal beliefs, perspectives, instincts and values.

Implicit knowledge is another common term that refers to knowledge derived from the careful and deliberate decomposing of tacit knowledge into a quantifiable and codifiable series of explicit knowledge. In other words, it is tacit knowledge in the process of becoming explicit knowledge.

An iceberg is frequently used as an analogy to represent the relationship between explicit and tacit knowledge, with explicit knowledge as the visible top of the iceberg and tacit knowledge as the iceberg’s unseen, underlying portion.

Knowledge Chain

In their book Corporate Instinct, Thomas Koulopoulos, Richard Spinello and Wayne Toms developed the concept of the knowledge chain. This chain has four links that determine the uniqueness and longevity of any organization: internal awareness, internal responsiveness, external responsiveness and external awareness.

Internal awareness is the ability of an organization to quickly assess its inventory of skills and core competency. Internal responsiveness is the ability to exploit internal awareness. External responsiveness is the ability to best meet the requirements of the market. External awareness is the mirror image of internal awareness.

KM Applications

The four applications of KM are intermediation, externalization, internalization and cognition. Intermediation is the connection between knowledge and people. Externalization is the connection of the knowledge to other knowledge. There are two fundamental components of externalization: the capture and storage, and the classification or organization of the knowledge. Internalization is the connection of knowledge to query. Cognition is the linking of knowledge to process. It is the process of making or mapping decisions based on available knowledge.

Impact of KM

KM has demonstrated an impact on business. In an economy based on knowledge, KM is the critical element of a business strategy that will allow an organization to accelerate the rate at which it handles new market challenges and opportunities. It does so by leveraging its most precious resources - collective know-how, talent and experience (intellectual capital).

Implementing a KM system offers several benefits, including:

- Reducing the dependency on tacit knowledge

- Minimizing the loss of intellectual capital

- Promoting creativity and innovation

- Providing more flexibility

- Increasing the response capacity and quality before changes occur

- Improving management quality and efficiency

- Improving integration with linked external parts (customers, suppliers, partners)

- Making organizational learning easier

- Reducing risks

- Facilitating decision-making

Maintenance and KM

Maintenance is one of the most prolific areas in an organization for producing knowledge, both explicit and tacit. For example, this would include handbooks for equipment installation and operation, procedures, checklists, asset records, periodical reports, technical books, reference tables, technical knowledge, etc.

Maintenance is one of the most prolific areas in an organization for producing knowledge, both explicit and tacit. For example, this would include handbooks for equipment installation and operation, procedures, checklists, asset records, periodical reports, technical books, reference tables, technical knowledge, etc.

Explicit maintenance knowledge should not be of great concern, as it is more of an issue of organization and classification. Tacit maintenance knowledge must be internalized. It coexists with intelligence and experience, and affects how decisions are made. For this reason, the primary repository for knowledge is in the heads of individuals. Electronic and paper-based knowledge repositories are merely intermediate storage points for information en route between people’s minds. Therefore, technical personnel should be considered as the repositories of an organization’s know-how (and often the know-why, too). This is particularly true for maintenance processes and tasks.

These raw goods of intellectual capital - experience and know-how - must be channeled and made available. Otherwise, innovation can be restricted. How and where this intellectual capital is being captured must also be evaluated. The goal is to capture and monitor this continuously developing intellectual capital and promote its leverage.

Procedures

To transfer knowledge about equipment and related maintenance tasks, a combination of accurate information, complete records and numerous photos will be needed. This knowledge transfer may be made between personnel inside the plant, such as operators or new employees, and/or to outside contractors through effective job-specific training and documentation. The key is to ensure the knowledge is transferred properly. This work must be performed consistently and in a quality manner each time. Documenting work processes and capturing the knowledge possessed by maintenance professionals should be a priority. Whether the organization refers to these as PMs, standard operating procedures or work processes, they must be documented properly.

Using CMMS

Most maintenance operations today employ computerized maintenance management systems (CMMS) to drive their maintenance tasks. Each work document can be tied to the CMMS so that when a PM is generated, a copy of the documented work tasks can go with it. However, the reality is that the information in these systems often has not been updated through the years, and there may be more tasks than personnel to perform them. The work tasks may also be poorly documented and offer little instruction. In this scenario, when maintenance professionals retire, their replacements (assuming there are replacements) will not have the same resident knowledge to perform the tasks adequately.

Documenting work tasks in the appropriate manner will help to prevent this situation from occurring and allow the organization to retain and transfer knowledge, improve/update historical practices, and enjoy greater flexibility. Indeed, the company must learn to manage knowledge in order for it to remain viable long term.

Apprenticeship Training Programs

An apprenticeship training program is a common method used to replace maintenance workers. The benefit of this type of program is that it can incorporate existing workers who understand the production processes and have good discipline and attendance records. The disadvantages of these programs are that they may take three to four years and are expensive to conduct.

Before beginning a training program, you should be assured that the candidates for training have the necessary skills to learn what is being presented. This can be accomplished by requiring specific qualifications or certifications. Of course, you must use caution, as these credentials are only as good as the curriculum at the institution granting them.

Mentors/Coaches

Another option when replacing workers is to train veteran maintenance personnel to be mentors or coaches and share their knowledge with new employees. For this approach to be sustainable, you must carefully select individuals who not only have experience but also the competency to serve as a mentor. Potential candidates should be able to perform several key functions, such as:

- Present issues in an understandable way

- Build collaboration and rapport

- Be respectful

- Be a good time manager

- Ask questions, formulate hypotheses and offer examples that promote knowledge transfer

- Balance individual and group activities

- Help apprentices achieve autonomy and confidence in the learning process

- Provide positive feedback

- Possess emotional intelligence

Keep in mind when implementing a KM system that you must record and update the existing knowledge of personnel who are close to retirement while also managing the knowledge transfer to new employees through procedures, training or mentoring. Maintenance operations especially should develop mechanisms to preserve their intellectual capital. Otherwise, this valuable experience and know-how will disappear when personnel quit or retire and take their knowledge with them.