Alternatives to Traditional Wear Particle Analysis

Many of the methodologies existing today for oil testing provide only one key parameter of diagnostic information such as particle size or chemical composition. While a single parameter can offer clues as to what is occurring in an engine or motor, more often than not it is inconclusive. Laboratories frequently recommend a battery of tests to obtain a more comprehensive diagnosis. This often leads to confusion as to how to interpret the data or even which method to request and how often. However, a new way of evaluating wear debris allows a complete diagnosis to be achieved with one test that can be performed by in-house maintenance technicians.

SEM/EDX

Historically, scanning electron microscopes (SEMs) have been viewed as manual imaging instruments that require qualified users in specialized environments. Recent advances in SEM technology have provided more compact, easy-to-use instruments applicable to a more industrial setting. When combined with an energy dispersive X-ray (EDX) detector, the SEM has the ability to perform quick, quantitative compositional measurements. An SEM not only can measure and record the size and shape of a wear debris particle, but it can also determine the particle’s elemental makeup, thereby combining the physical and chemical worlds of wear analysis into one.

Historically, scanning electron microscopes (SEMs) have been viewed as manual imaging instruments that require qualified users in specialized environments. Recent advances in SEM technology have provided more compact, easy-to-use instruments applicable to a more industrial setting. When combined with an energy dispersive X-ray (EDX) detector, the SEM has the ability to perform quick, quantitative compositional measurements. An SEM not only can measure and record the size and shape of a wear debris particle, but it can also determine the particle’s elemental makeup, thereby combining the physical and chemical worlds of wear analysis into one.

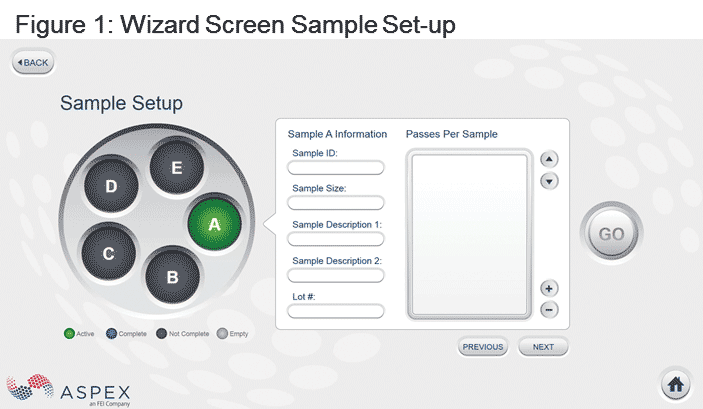

An automated SEM/EDX wear debris analysis system uses a single hardware control configuration for both the SEM and EDX components, making it more compact and robust for industrial wear debris applications. Simplifying the system even further, the instrument is set up to operate via pre-programmed recipes that allow the user to walk up to the system, load the samples, initiate the run and walk away, only to come back later to sample reports. All calibration and instrument operation is automated and does not require user management or monitoring.

Utilizing back-scattered electrons (BSE) on an SEM enables the system to take advantage of the strong correlation of the average atomic number of the particles and the BSE signals. Hydrocarbons and other particle types with a low average atomic number tend to scatter fewer electrons than metallic particles and other particle types with a high average atomic number. Thus, in a BSE image, metallic particles look bright, while organics look dark.

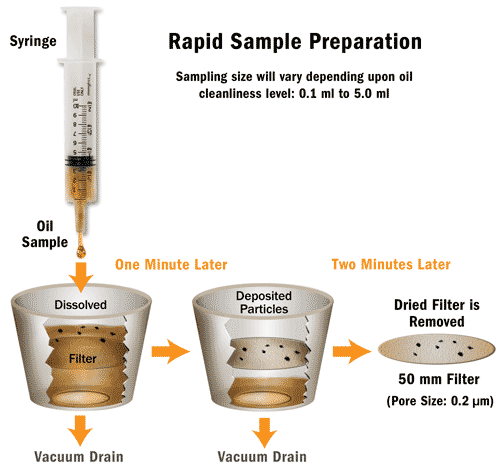

One of the main differences between SEM/EDX and traditional methods is in its sample preparation. Figure 2 illustrates the sample preparation and analysis expectations of the SEM. Ultimately, a small portion of the oil sample is needed to prepare a representative sample on a filter membrane. Once loaded into the system, these analyzers move the beam across the full field through a sequential array of fairly coarse steps, constantly searching for a particle of interest and moving to the next field instead of capturing a high-resolution image of the frame. A particle is detected when the contrast intensity level of the particle exceeds the predefined threshold background set for each analysis activity.

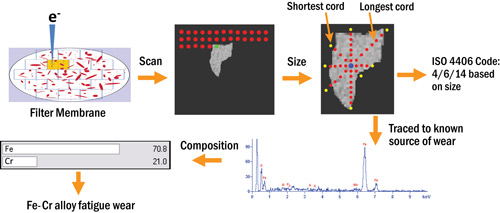

This particle-sizing sequence initiates a rotating 16-cord algorithm to measure the particle’s morphological characteristics. As illustrated in Figure 3, a series of cords are drawn across the diameter and through the center of the particle at equal angular spacing. Particle size and shape measurements are then derived from these cords. All variables are then collected for each unique particle in sequence across the filter.

After the particle is detected and measured, an energy dispersive X-ray spectrum is acquired at the center, perimeter or along each cord for every particle detection event. Figure 3 illustrates the dynamic scan and rotating 16-cord algorithm during the particle measurement and EDX elemental X-ray collection phase.

Once particles are characterized by size, shape and elemental composition, user-defined rules place them into a “class.” For instance, if the user is interested in only high iron samples, a rule can be put in place to classify all particles with high iron content. Those particles will then be grouped and reported in the assigned “class.” If needed, the particles can be relocated and further examined by the operator. The system provides a customizable reporting tool and automatically generates reports of the analyses. A database stores all analysis results for monitoring long-term trends with engine or gearbox wear.

Comparison of Traditional Methods with SEM/EDX Results

Table 1 presents a side-by-side comparison of various analytical methods. While each of these methods has advantages, SEM/EDX can provide users with a comprehensive analysis as well as more knowledge in dealing with wear debris. The value of the technology is that not only does it give the size, shape and chemical composition of each particle in the sample, but it also permits the user to classify each of those particles based on their chemical composition. This allows classification of the particles into various rules or classes and enables the user to instantaneously identify if particles are wear debris or just steel alloys, carbon, mineral salts or fibers. Diagnosing machine wear becomes much easier because little to no interpretation of the data is needed.

| Feature | Automatic Particle Counter | Analytical Ferrography | ICP Elemental Analysis | RDE Elemental Analysis | SEM/EDX |

|---|---|---|---|---|---|

| Sample Preparation Requirements | Usually | Yes | Yes | No | Yes |

| Particle Detection Range (microns) | 2-100 | 2-500 | <3 | <7 | 0.2-2000 |

| Individual Particle Size and Shape | Usually | Yes | No | No | Yes |

| Total Element Chemical Analyses Range | No | No | 38 | 32 | 98 |

| Particle Classification by Chemistry | No | Limited | No | No | Yes |

| Particle Classification by Morphology and Chemistry | No | Yes | No | No | Yes |

| Analyses Time (minutes) | 5 | 10 | 3 | 3 | 10 to 30 |

| Ease of Use(1=easy 5=moderate 10=difficult) | 5 | 10 | 5 | 3 | 1 |

| Particle Size Distribution | Yes | No | No | No | Yes |

| Automated Trending | Yes | Limited | Yes | Yes | Yes |

In order to demonstrate the power of the knowledge gained from SEM/EDX when compared to other technologies, real-world samples were collected and tested. Three unique engine oil samples obtained from a local car dealership were submitted to an oil testing lab for analyses. For comparison purposes, several methods were chosen for third-party testing including inductively coupled plasma (ICP) elemental analysis, particle counting via pore blockage and direct-reading ferrography. Each sample was subsampled representatively and also prepared for SEM testing at an in-house laboratory. Results from the third-party laboratory were received and compiled for comparison to the SEM/EDX results.

In order to demonstrate the power of the knowledge gained from SEM/EDX when compared to other technologies, real-world samples were collected and tested. Three unique engine oil samples obtained from a local car dealership were submitted to an oil testing lab for analyses. For comparison purposes, several methods were chosen for third-party testing including inductively coupled plasma (ICP) elemental analysis, particle counting via pore blockage and direct-reading ferrography. Each sample was subsampled representatively and also prepared for SEM testing at an in-house laboratory. Results from the third-party laboratory were received and compiled for comparison to the SEM/EDX results.

It should be noted that the purpose of the data comparisons was to demonstrate the added value and benefit of SEM/EDX testing and not to evaluate the data from the third-party lab.

Particle Count Results

Table 2 presents the particle count data for both the SEM and pore blockage methods for three samples. The pore blockage data from the third-party laboratory was reported using the ISO 4406 reporting standard. For all SEM data, this reporting standard was maintained, but it was also decided to report particles larger than 2 microns to provide an additional perspective on the data.

| 4406 ISO BIN | SAMPLE 1 | SAMPLE 2 | SAMPLE 3 | |||

|---|---|---|---|---|---|---|

| SEM | Pore Blockage | SEM | Pore Blockage | SEM | Pore Blockage | |

| >2 µm | 9,226 | 16,180 | 3,198 | |||

| >4 µm | 4,254 | 5,513 | 5,898 | 10,096 | 912 | 4,018 |

| >6 µm | 2,228 | 2,144 | 2,674 | 3,926 | 404 | 1,562 |

| >14 µm | 296 | 163 | 112 | 299 | 66 | 119 |

| >50 µm | 12 | 7 | 4 | 13 | 0 | 5 |

| >100 µm | 8 | 0 | 0 | 0 | 0 | 0 |

In the first sample, the particle count was fairly comparable between the SEM and pore blockage results. In the second and third samples, the sizes and counts of the actual particles varied. This could be attributed to sample representativeness between the two samples that were divided for submission to the lab. While this seems likely, it could indicate some of the differences in the testing methodologies, including sample preparation, and particle sizing techniques. For example, pore blockage technology (ISO 21018-3) does not actually count individual particles but rather estimates the particle size distribution using an algorithm based on a measured flow decay across a membrane or a rise in differential pressure. A total number of particles is calculated using an algorithm derived from extensive empirical testing. On the other hand, SEM detects, scans and measures each particle individually, providing size analyses accurate to 0.5 microns.

In all three samples, the largest discrepancies between the two technologies came in the smaller sized particles. While the ISO standard requires that only particles larger than 4 microns are reported, the SEM data could demonstrate the limitations of the pore blockage method as the particle sizes get smaller. Coincidently, this same range of particle sizes (between 2 and 4 microns) would also represent the particles reported by the ICP results.

Chemical Composition Results

Table 3 presents the chemical composition data for all three samples in parts per million (ppm) as reported by the third-party laboratory. It should be noted that no particles larger than 3 to 4 microns would be detected in these results due to the limitations of ICP. Based on the table, the majority of the components in each of the three samples were salts and minerals such as calcium, phosphorus and sodium. There was a significant portion of zinc or molybdenum and boron, which could be coming from additives, coatings and possibly some bearing wear. All three samples also showed some iron and copper, which would suggest motor wear. However, metals like aluminum, tin, nickel and chromium were all but absent.

| Iron | Copper | Lead | Aluminum | Tin | Nickel | Chromium | Titanium | Vanadium | Silver | Silicon | Boron | Calcium | Magnesium | Phosphorus | Zinc | Barium | Molybdenum | Sodium | Potassium | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample 1 | 5 | 1 | 0 | 2 | 2 | 0 | 0 | 0 | 0 | 0 | 10 | 97 | 1,796 | 7 | 571 | 700 | 0 | 71 | 135 | 4 |

| Sample 2 | 12 | 5 | 4 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 8 | 0 | 1,562 | 8 | 643 | 787 | 1 | 3 | 375 | 0 |

| Sample 3 | 14 | 37 | 0 | 3 | 2 | 0 | 0 | 0 | 0 | 0 | 6 | 159 | 1,964 | 9 | 630 | 764 | 15 | 83 | 36 | 5 |

The key difference with SEM/EDX data is that you not only get the individual particle size and shape but also the actual particle chemistry for each particle detected. The particle chemistries can then be classified into various “rule classes,” which are established based on various metal chemistries. Tables 4 and 5 present the SEM/EDX results of each of the particle counts for all three samples classified by standard wear debris chemical rule classes. These classes indicate both metallic (Table 4) and non-metallic (Table 5) rules.

| 100Cr6 | 16MnCr5 | Cr | Cr Coating | Cr-Ni-Mo | Al2O3 | Al-Alloy | Al-Zn | Brass | Bronze CuSn | Cu | Fe-Cu | High Alloy Steel | Low Alloy Steel | Low Fe | Sn | Steel | Zn Coating | Zn Misc. | Zn-Cr Coating | Zn-P Coating | Ni | Mn-P Coating | Non-Ferrous Metal | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample 1 | 18 | 70 | 14 | 7 | 1 | 0 | 0 | 3 | 0 | 1 | 8 | 19 | 22 | 30 | 41 | 12 | 53 | 37 | 396 | 10 | 29 | 4 | 0 | 34 |

| Sample 2 | 233 | 733 | 11 | 7 | 3 | 0 | 0 | 2 | 0 | 5 | 2 | 27 | 260 | 386 | 493 | 20 | 359 | 20 | 908 | 10 | 74 | 11 | 0 | 18 |

| Sample 3 | 22 | 64 | 11 | 18 | 7 | 0 | 0 | 0 | 0 | 0 | 1 | 11 | 20 | 21 | 61 | 3 | 29 | 6 | 243 | 0 | 8 | 0 | 0 | 7 |

Table 6 shows the most beneficial form of data collected via SEM/EDX. It not only offers the size and shape of each particle but also a chemical classification. This can be an invaluable tool for diagnosing engine wear because the user can consider both the size and chemical composition of the particles to determine what is happening inside the engine.

| High Ca | Ca Misc. | SiAl Mineral | Lubricants | Mineral | Mineral Fiber | Misc. | Misc. Salts | SiAlCa Mineral | Si-O/Si-C/Si-N | |

|---|---|---|---|---|---|---|---|---|---|---|

| Sample 1 | 82 | 1,078 | 86 | 84 | 1,694 | 121 | 64 | 151 | 223 | 221 |

| Sample 2 | 9 | 2,707 | 4 | 204 | 354 | 214 | 12 | 975 | 11 | 18 |

| Sample 3 | 24 | 633 | 5 | 41 | 233 | 51 | 7 | 50 | 10 | 13 |

For instance, in Table 6 a rule for a stainless-steel type of material (or 100Cr6) would be any particle with its highest component as iron greater than 70 percent, along with chromium greater than 1 and less than or equal to 3, manganese less than 1 percent, zinc and chromium less than 5 percent and titanium less than 3 percent. This, along with the second rule classification of 16MnCr5, indicates stainless steel and would suggest that some bearing wear is occurring, especially when considering the larger particle sizes.

In comparing these results to the ICP data, chromium was not detected in any of the samples, including the second sample. When looking at the larger particles detected in the second sample, you can see that various steel (low and high alloy) and stainless-steel components (16MnCr5) are present at particle sizes larger than 50 microns. Again, wear debris of this size could signify significant engine wear.

| Rule Class | >=2 | >=4 | >=6 | >=7 | >=10 | >=14 | >=50 |

|---|---|---|---|---|---|---|---|

| 100Cr6 | 233 | 466 | 224 | 120 | 72 | 22 | 0 |

| 16MnCr5 | 733 | 1466 | 766 | 376 | 238 | 86 | 12 |

| Al-Zn | 2 | 4 | 2 | 2 | 2 | 0 | 0 |

| Cr | 11 | 22 | 16 | 10 | 6 | 0 | 0 |

| Cr Coating | 7 | 14 | 6 | 4 | 4 | 4 | 2 |

| Cr-Ni-Mo | 3 | 6 | 2 | 2 | 0 | 0 | 0 |

| Fe-Cu | 27 | 54 | 40 | 30 | 26 | 4 | 0 |

| High Alloy Steel | 260 | 520 | 204 | 82 | 34 | 12 | 2 |

| High Ca | 9 | 18 | 12 | 4 | 4 | 0 | 0 |

| Low Alloy Steel | 386 | 772 | 324 | 148 | 82 | 36 | 8 |

| Low Fe | 493 | 986 | 408 | 190 | 88 | 20 | 4 |

| Lubricants | 204 | 408 | 114 | 54 | 16 | 2 | 0 |

| Ni | 11 | 22 | 2 | 0 | 0 | 0 | 0 |

| Steel | 359 | 718 | 388 | 200 | 128 | 40 | 12 |

| Zn Coating | 20 | 40 | 12 | 6 | 6 | 0 | 0 |

| Zn Misc. | 908 | 1816 | 526 | 220 | 106 | 24 | 6 |

| Zn-Cr Coating | 10 | 20 | 4 | 0 | 0 | 0 | 0 |

| Zn-P Coating | 74 | 148 | 36 | 6 | 2 | 0 | 0 |

When examining the smaller sized particles in the second sample, you can see not only the stainless particles but also a significant amount of tin, nickel and chromium particles, which could be indicative of slight engine wear. These metals were not detected at all in the ICP data for the second sample.

Ferrography Results

Direct-reading ferrography was also performed by the third-party laboratory for each of the samples. All three samples were found to have either light wear or moderate wear. No significant or abnormal particles were reported for any of the samples. Ferrous particles were between 5 to 15 microns in size for each of the three samples. Comparing this to the SEM/EDX data, there were numerous ferrous particles in each of the samples, with some as large as 50 microns in the second sample (Table 6).

Benefits of SEM/EDX

For years, wear debris and oil testing have been performed using methods such as ferrography and particle counters in conjunction with ICP or rotating disk electrode (RDE). Information gained from these technologies has been helpful in diagnosing engine or gearbox wear, but users still struggle with knowing how to interpret data from the laboratory. SEM/EDX offers an alternative to traditional wear debris and particle analysis, and can now be used by a technician with minimal training or a limited scientific background. It can take the place of two or three traditional oil testing methods by allowing the user to report both particle and chemical composition data. The data can then be segmented based on user-defined classes, and clear classifications of wear debris particles can be studied for immediate feedback on gearbox or engine conditions. SEM/EDX can also complement your current oil testing program by offering more intuitive data to diagnose a suspected issue when more traditional testing raises warning signs but is not conclusive.

Regardless of your testing program, it is important to keep in mind that establishing historical baselines and running consistent testing protocols will provide historical wear profiles that can give timely indicators of the changes in the status and rate of wear.