Gearbox Condition Monitoring Through Used Oil Analysis

When the city of Fort Collins, Colorado, purchased new planetary gearboxes for its wastewater sludge dewatering centrifuges, it decided to implement a proactive used oil analysis maintenance strategy. This decision resulted in significant cost savings.

When the city of Fort Collins, Colorado, purchased new planetary gearboxes for its wastewater sludge dewatering centrifuges, it decided to implement a proactive used oil analysis maintenance strategy. This decision resulted in significant cost savings.

Unconventional Machinery

Two of the machines were installed new in 1998 at a cost of $619,000 each. They replaced existing sludge dewatering belt-filter presses. The new machines were complex by comparison, requiring additional research in the proper maintenance to ensure years of cost-effective, reliable service. Appropriate maintenance tasks also had to be developed for this new equipment.

The centrifuges are critical to the Water Reclamation and Bio-Solids Division. The belt-filter presses have since been decommissioned, although technically they are on standby as backups. However, for various reasons, startup and re-use of these filter presses are not encouraged.

Each centrifuge has a bowl assembly that is V-belt driven by a 300-horsepower, AC-induction motor at approximately 1,748 revolutions per minute (rpm). The driven bowl speed is roughly 2,800 rpm. A back-driven scroll assembly within this bowl rotates at approximately 3 rpm less than bowl speed. The scroll regulates the rate at which the dewatered solids exit the machine in order to obtain an optimum percentage of dewatered bio-solids. The scroll is powered by a back-drive system that consists of a 100-horsepower DC motor and synchronous belt drive turning the planetary gearbox. The average service duty is approximately six to 10 hours per day, four to five days per week. Loss of one of these centrifuges would mean extended hours of operation for the remaining centrifuge and more labor hours for the operations staff.

A Proactive Maintenance Strategy

After the manufacturer’s maintenance recommendations and guidelines were reviewed, it was concluded that the proper gear oil level would need to be maintained. The manufacturer’s lubrication schedule specified an annual oil drain and replacement of the gear oil. The quantity and type of oil required was 15 quarts of synthetic gear oil. The manufacturer also suggested a gearbox exchange program in which the gearbox would be replaced every two years with a factory-reconditioned gearbox. The exchange cost was estimated at $8,000 each, not including labor.

After the manufacturer’s maintenance recommendations and guidelines were reviewed, it was concluded that the proper gear oil level would need to be maintained. The manufacturer’s lubrication schedule specified an annual oil drain and replacement of the gear oil. The quantity and type of oil required was 15 quarts of synthetic gear oil. The manufacturer also suggested a gearbox exchange program in which the gearbox would be replaced every two years with a factory-reconditioned gearbox. The exchange cost was estimated at $8,000 each, not including labor.

The city began exploring ways to extract a representative used oil sample from these gearboxes for oil analysis. If the condition of the gearboxes could be determined through a predictive strategy or a root cause analysis proactive strategy, symptoms of early impending failure could be monitored and detected. The root causes of these detected symptoms could then be identified and eliminated, or at least controlled. Ultimately, oil drains could be extended and the associated maintenance costs reduced with less generation of used oil and less need for new oil replacement. There would also be a greater understanding of the condition of the new gearboxes, increasing reliability and decreasing maintenance costs.

Obtaining Representative Oil Samples

Due to the planetary design of the gearboxes, it was not possible to obtain a representative oil sample during normal operation, and extracting the samples would not be conventional. A small, rigid brass pipe nipple was fabricated into the gearbox oil plug to provide a means of collecting a sample via gravity into an ultraclean container supplied by the offsite oil analysis laboratory.

Due to the planetary design of the gearboxes, it was not possible to obtain a representative oil sample during normal operation, and extracting the samples would not be conventional. A small, rigid brass pipe nipple was fabricated into the gearbox oil plug to provide a means of collecting a sample via gravity into an ultraclean container supplied by the offsite oil analysis laboratory.

The sample was collected immediately after shutdown. If it was not obtained within 30 minutes of shutdown, the gearbox outer shell and input shaft were manually rotated numerous revolutions before flushing the sample collection fitting and taking the sample.

After frequent oil sampling to establish baseline data, the sample frequency was initially set at quarterly and later updated to 500 hours of operation. An hour meter was also installed on the drive motor instrumentation.

Representative used oil samples, as well as new oil samples, were collected, labeled with all pertinent data and sent to the oil analysis lab. Cleanliness targets were set at ISO 18/16/13. The new samples would provide a means of determining the physical properties and additives within the oil.

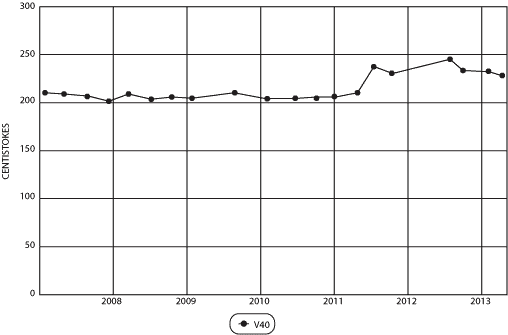

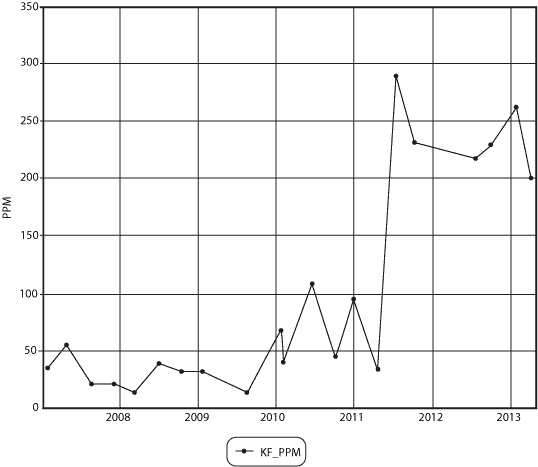

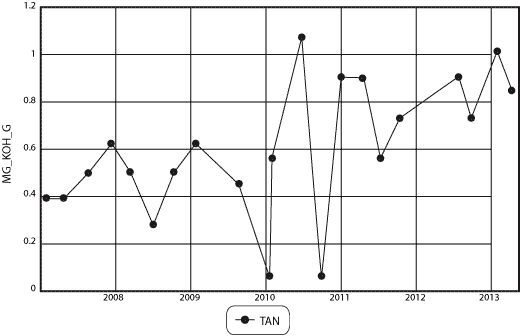

The lab’s oil analysis test slate included a variety of standard tests such as ISO cleanliness, kinematic viscosity at 40 degrees C and 100 degrees C, water by Karl Fischer, acid number and elemental spectroscopy. All of the oil analysis reports and recommendations received from the lab were closely reviewed to monitor the oil’s physical properties, contamination and/or wear metals.

Extending Oil Drains

The oil was not replaced at the manufacturer’s suggested one-year runtime interval because the oil analysis reports continued to be favorable. ISO cleanliness was diligently maintained through offline kidney-loop filtration using micro-glass filters.

As the two-year maintenance interval approached, there was no data-driven reason to replace the gear oil, let alone to exchange the gearboxes. The original equipment manufacturer (OEM) was contacted to inquire whether exchanging the gearboxes was still recommended. The OEM’s response was, “You are doing what no other customer of ours currently does. I’d keep it up. The exchange program is not necessary with this comprehensive strategy.”

Continued Cost Savings

Now fast forward to 2013. The two planetary gearboxes are still in service, and all parameters continue to be carefully monitored. The original oil was replaced with an ISO viscosity grade 220 polyalphaolefin (PAO) synthetic gear oil after the 10 gallons of oil that came with the new machines ran out. Considering the initial estimate of $8,000 per gearbox every two years, the cost savings of reconditioned gearbox purchases alone totaled more than $112,000.

The city of Fort Collins’ oil analysis program continues today in the capable hands of the Water Reclamation and Bio-Solids Division’s maintenance staff. These skilled craftsmen still employ a proactive maintenance strategy with these gearboxes as well as with many other assets in the division. On several occasions, in order to thoroughly clean the internal cavities of these machines, the staff has completely disassembled, cleaned and rebuilt each of these centrifuges, saving the city tens of thousands of dollars. Through it all, the planetary gearboxes have been removed and re-installed without the need for replacement.

While the city’s oil analysis program includes a number of other assets, with several worthy of their own testimonials, the proven strategy for these two planetary gearboxes continues to speak for itself.

About the Author

David Kintner Jr., Leprino Foods