What a Maintenance Reliability Program Should Look Like

The hardest part of starting a reliability program is freeing up time to work on proactive tasks. The maintenance department at Leprino Foods spent most of its time repairing broken equipment. The technicians were so busy that they didn’t have time to think about how to proactively solve their issues. There was a lack of organization. Too much time was spent looking for original equipment manufacturer (OEM) manuals, searching for parts and troubleshooting equipment.

The hardest part of starting a reliability program is freeing up time to work on proactive tasks. The maintenance department at Leprino Foods spent most of its time repairing broken equipment. The technicians were so busy that they didn’t have time to think about how to proactively solve their issues. There was a lack of organization. Too much time was spent looking for original equipment manufacturer (OEM) manuals, searching for parts and troubleshooting equipment.

Slowly the idea of working smarter not harder was introduced. For instance, instead of hunting for OEM manuals in an unorganized drawer in the parts room, parts and other items were scanned and searched for electronically. The technicians worked on their troubleshooting techniques to shorten the time it took to make repairs and minimize the mistakes they were making.

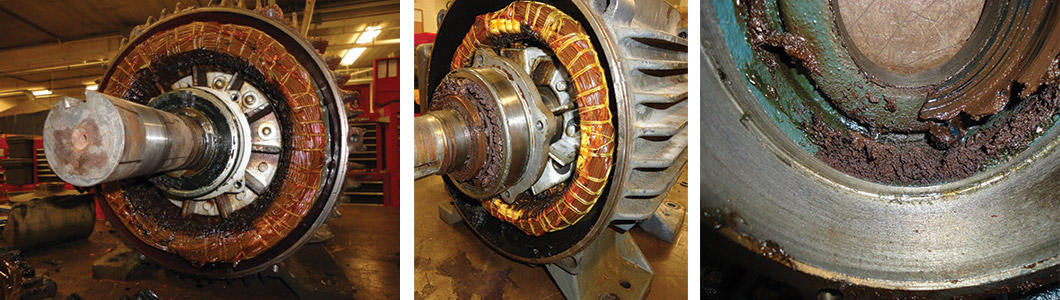

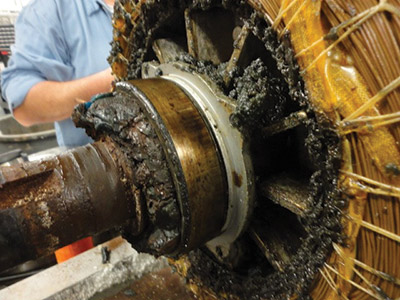

The idea of asking why was encouraged. Why were a high number of motor and AC drive failures being experienced? Why were gearboxes failing? Why was there an excessive amount of grease in the windings in almost all the motors that were inspected after failure? The technicians were accustomed to removing a motor, putting a repair tag on it and turning it over to the parts room to be sent out for repair before moving onto the next asset.

This remains a learning process. Considerable time was spent demonstrating how a proactive mindset can make all the difference. Through experience, it was learned that most moderate to complex issues could be rooted all the way back to the most basic task. For example, a bearing may be undergreased or overgreased. The wrong lubrication may also be used on the wrong application.

Starting with the Worst Actors

The worst actors had to be addressed in the plant. Utilizing a computerized maintenance management system (CMMS), the functional locations that seemed to have the biggest issues were identified along with the most damaging failure modes.

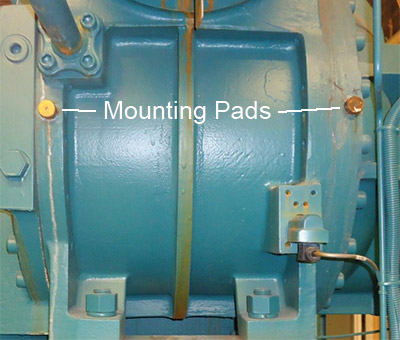

One case study from the plant in Allendale, Michigan, involved a whey-powder dryer system. The plant was experiencing premature bearing failure with all six of the dryer exhaust fans and was lucky to get a year of service life from the load and motor bearings. After a failure analysis was performed, an action register was selected and a multitude of issues began to be addressed, such as researching and observing installation, lubrication, loading and precision maintenance practices. Some of the issues discovered were incorrect bearing installation, bearing overgreasing, improper belt tensioning and incorrect sheave alignments.

During installation, it was determined that the bearings weren’t being gapped properly on the shaft. The initial amount of grease applied to the bearing housing was also excessive. Everything was a “hurry-up” situation, so the belts were never tensioned properly, nor were the sheaves aligned. In fact, the V-belts were replaced a couple of years ago, so the correct tensioning gauges were not even in-house.

An experienced application engineer was brought in to analyze this problem along with some other areas that had lubrication application concerns. It was soon realized that all of the technicians and managing personnel believed that more grease was always better. The plant was also caught in the trap of trying to use one grease for all of its bearing applications.

Standard operating procedures (SOPs) were developed for bearing installation practices, belt tensioning and laser alignments. Currently, the technicians are being trained on how to perform these functions correctly and efficiently. They have come to understand that making something as simple as possible will assist with the permanent implementation of a new methodology.

Fine-tuning Lubrication and Oil Analysis

The plant continues to fine-tune its lubrication practices. This has been the hardest part of the transformation. Methods have been developed to alert personnel when there is possible overgreasing of a bearing, but the details are still being worked out for achieving the right amount of grease at precise intervals.

The plant continues to fine-tune its lubrication practices. This has been the hardest part of the transformation. Methods have been developed to alert personnel when there is possible overgreasing of a bearing, but the details are still being worked out for achieving the right amount of grease at precise intervals.

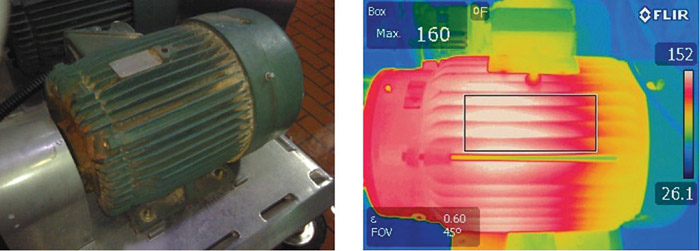

Another major step at Allendale was the implementation of a condition monitoring program. In the past, the plant experienced limited success with predictive tools including a vibration meter, outsourced infrared imaging and oil analysis. This was a great first step, but it was limited for a number of reasons. The infrared imaging agreement was restricted to twice a year. The technicians were tasked with making repairs, with some more successful than others. The effectiveness of the repairs wouldn’t be known for another six months. Electrical problems occurred as a direct result of these missed opportunities.

Two 100-horsepower motor failures and three large AC drive failures were experienced in one year. The failure modes were electrical and could have been avoided if infrared routes had been developed for these areas. The vibration routes were based on a total root mean square (RMS) meter, which simply looks at total vibration in a system. If the system’s vibration increased, the technician generated a work order to investigate.

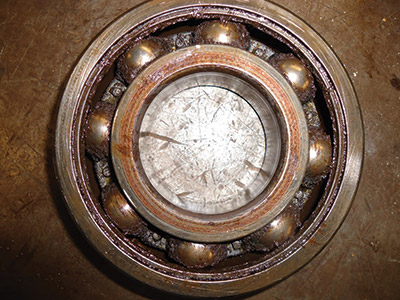

While the oil analysis program functioned well, rarely did anyone pay attention to it. Samples were pulled and sent to the lab, but the plant seldom acted on the results. Reports noted contamination and gear wear with suggestions to “replace oil” and “investigate gear wear.” Unfortunately, the majority of the recommended actions were not completed. If the planner/scheduler had time, he would occasionally look at some of the issues and create work orders, but there was no consistency.

While the oil analysis program functioned well, rarely did anyone pay attention to it. Samples were pulled and sent to the lab, but the plant seldom acted on the results. Reports noted contamination and gear wear with suggestions to “replace oil” and “investigate gear wear.” Unfortunately, the majority of the recommended actions were not completed. If the planner/scheduler had time, he would occasionally look at some of the issues and create work orders, but there was no consistency.

Streamlining Condition Monitoring

The first step to correct this was to reduce the amount of equipment being monitored. Previously, everything was monitored, including a $100 gearbox that wouldn’t shut down the process. The plant’s CMMS contained an ABC indicator with a cost-of-failure descriptor. Any asset ranked from six to nine was considered a critical piece of equipment. Of course, this would change over time, but it was a good starting point.

Specification sheets were created, and critical failure modes were determined for the equipment to be monitored. A large portion of the machines to be tested had some redundancy. However, just because a piece of equipment was to take the place of another didn’t mean it couldn’t be considered critical. Many of these setups weren’t cycled or maintained properly.

Once all the logistics were accomplished, such as determining routes, developing predictive maintenance work orders and installing vibration pads on machines, the training portion of the program began. The budget included thermography and vibration analysis certifications as well as Machine Lubrication Technician Level I certification through the International Council for Machinery Lubrication.

Once all the logistics were accomplished, such as determining routes, developing predictive maintenance work orders and installing vibration pads on machines, the training portion of the program began. The budget included thermography and vibration analysis certifications as well as Machine Lubrication Technician Level I certification through the International Council for Machinery Lubrication.

The main focus for the condition monitoring program was the development of the vibration analysis program. At first, no one at the plant knew how to analyze anything. Testing equipment was researched, and a piece of vibration equipment was purchased that could diagnose most of the plant’s issues without in-house analysis. The analysis equipment would also produce vibration spectrums and time waveforms.

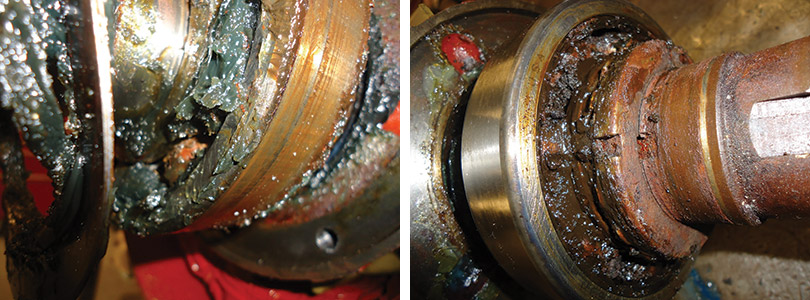

Two factors prevented success with this program. The first was the lack of repeatability in data acquisition. The second was not having a solid grasp of how the equipment worked in the processes. Plant personnel set out to gain this knowledge. They spent a great deal of time learning how to collect data, realizing that vibration pads worked best. Installing brass pads in the mounting locations allowed for repeatable data collection. The accelerometer screwed right into the mount, allowing for the same placement every time. Techniques were also developed to place systems into manual mode during the test in order to control loading. This wasn’t always perfect, and not every system could be switched to manual mode when needed. The work order was rescheduled for a later date if this was the case.

Initially, the plant adhered to the diagnosis from the testing equipment until it was noticed that some of the diagnoses weren’t always accurate. To continue the program’s progress, the decision was made to develop the ability to analyze spectrums. Certification training began soon afterward. This was a huge step. While personnel were accustomed to the idea of using test equipment to monitor machines for failures, they didn’t realize how important it would be to rule out certain repairs. They have since successfully used the equipment to identify flow noise and particular attributes of a system such as eccentric rotors.

Initially, the plant adhered to the diagnosis from the testing equipment until it was noticed that some of the diagnoses weren’t always accurate. To continue the program’s progress, the decision was made to develop the ability to analyze spectrums. Certification training began soon afterward. This was a huge step. While personnel were accustomed to the idea of using test equipment to monitor machines for failures, they didn’t realize how important it would be to rule out certain repairs. They have since successfully used the equipment to identify flow noise and particular attributes of a system such as eccentric rotors.

Frequently, work orders are generated to have a gearbox or motor repaired, only to discover that isn’t the issue at all. In one recent example, the work order stated, “There is a loud vibration and noise, which seems to be coming from the primary gearbox.” This wasn’t on the critical equipment list, so it wasn’t regularly monitored at this point. However, the gearboxes were expensive to replace, and a considerable amount of labor was required to complete the repair. A vibration test was performed. After analysis, it was determined that there were harmonics out to the tenth order of the motor speed. The technician was asked to lock it out, remove the belt and test the motor. The motor ended up being the issue. It had loose, out-of-tolerance end bells. A new motor was installed, and the entire system was retested. The new test results revealed no further problems.

Deploying Infrared Thermography

Prior to developing its infrared program, the plant outsourced this function. As the program was built and equipment was purchased, the first thing noticed was that many of the previously made repairs were still exhibiting the same hot spots. A number of steps were needed to get the program up and running. The image collection process was simplified by building templates for the camera. Now, whenever an area is to be surveyed, the templates for the area can be downloaded. Before, it took two predictive technicians to complete a survey - one to operate the camera and another to open and shut the motor control centers. Image analysis was performed once the images were downloaded to their respective folders.

The boundaries of the original infrared imaging route were expanded to include roof panels and some critical equipment subpanels that were not inspected initially. In addition, a standard operating procedure was developed to generate a work order for any deficiencies found. This included a follow-up infrared scan to ensure the anomaly had been corrected.

While infrared and vibration routes have been added, the plant is also in the process of re-evaluating its PMs to eliminate tasks that will be covered by infrared, vibration, oil analysis or motor analysis.

Recently, an offline motor tester was purchased. This provides the ability to find winding faults and grounded windings. It can also be used to test for broken rotor bars and eccentricity. The meter can measure impedance, phase angle, current-to-frequency response, etc.

During the last two years, the plant’s emergency work orders have trended down each year, while unplanned work orders have risen only slightly. However, the unscheduled work-order cost increase will involve maintenance and repairs only; no downtime will be incurred. Of course, the plant’s preventive maintenance program will continue to be adjusted. After all, a proactive mindset never stops.

About the Author

David Kintner Jr.