Ask the Experts

"What is the preferred method for minimizing the content of unwanted debris in lube oil? We are talking about diesel engines with up to 2,000 liters of oil in the sump. The oil is monitored regularly by the oil supplier, which tells us when to change. However, the manufacturer recommends an oil change every 1,000 hours. We installed an offline filter, and the oil company report said the oil was useable up to 3,000 hours."

"What is the preferred method for minimizing the content of unwanted debris in lube oil? We are talking about diesel engines with up to 2,000 liters of oil in the sump. The oil is monitored regularly by the oil supplier, which tells us when to change. However, the manufacturer recommends an oil change every 1,000 hours. We installed an offline filter, and the oil company report said the oil was useable up to 3,000 hours."

For a long time, we have used centrifugal purifiers, which have done a good job, but we also know they have their limitations when it comes to removing smaller and lighter particles from the oil. We are now looking into substituting the purifiers with offline filtration, which would be able to take out smaller particles along with water. Then we have glycol and fuel dilution to consider as well. We know we have to maintain the engines regarding these matters, but our main issue is to find out what is the best purification method of diesel engine lube oil. Is it a purifier or bypass filtration?"

First, you shouldn't allow oil suppliers to conduct the analysis and tell you when to change the oil. It is in their best interest for you to perform more frequent oil changes than may be required. Instead, use an independent lab test and change the oil based on the results. You may find that you are able to get more life from the oil. Remember, world-class lubrication programs use a condition-based approach rather than a time-based approach for lubricant change-outs.

Secondly, there is no mention of testing the oil upon receipt or prior to transfer. Studies have shown that it is 10 times more expensive to remove contaminants once they are in the oil. Your oil should be tested upon receipt to ensure that you are receiving clean oil from your supplier. In addition, every time the oil is transferred from one container to another it should pass through a filter. Use quick-connect fittings and a product-dedicated filter cart to fill and drain oil from sumps to stop particle ingression.

If you have issues with either fuel or glycol in your oil, removing those contaminants should not be your focus. Having fuel/glycol in the oil is only a symptom, so you must fix the problem. Once these fluids find their way into your oil, they are very difficult and expensive to remove. Check the system for coolant leaks and fix them. In the case of fuel, look for problems with injectors or air filters, which will affect the fuel/air ratio and can cause soot loading.

The best method of purification would be to use a combination of both purifiers and bypass filtration, since each has its limitations. Centrifugal purifiers are good at removing larger particles and water but not for removing the smaller organo-metallic particles, which a filter will remove. If you already have purifiers, keep them and add bypass filtration.

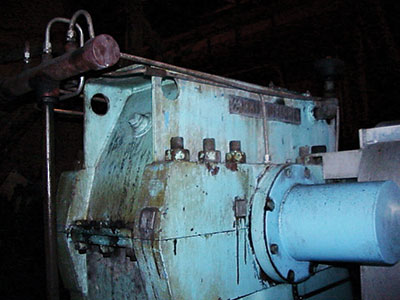

“My initial thought was that this could possibly be the residue from a rust-preventive fl uid. However, this gearbox has been used for a period of time. Is it possible that this is seal material or a sealant? If not, what could be causing this waxy residue and how can it be prevented?” Waxy residuals are not as prevalent as sludge or solid sediment but can be generated by several sources depending on the fl uids used, the contaminants present in the gearbox and the operating temperatures.

“My initial thought was that this could possibly be the residue from a rust-preventive fl uid. However, this gearbox has been used for a period of time. Is it possible that this is seal material or a sealant? If not, what could be causing this waxy residue and how can it be prevented?” Waxy residuals are not as prevalent as sludge or solid sediment but can be generated by several sources depending on the fl uids used, the contaminants present in the gearbox and the operating temperatures.

A common source is present in some mineral oils. When operating at low temperatures (0 to 30 degrees F), waxes existing in these lubricants may precipitate. Water contamination can also intensify this effect. Other precipitations may be produced by a variety of causes such as crosscontamination of different lubricants (including synthetics), the use of assembly oils, employing certain types of additives or even contaminants from the environment.

In order to determine the root cause of the waxy material, you may wish to analyze it using Fourier transform infrared (FTIR) or X-ray fl uorescence (XRF) spectroscopy and identify its properties. This information along with the machine’s maintenance/ operation history can help you pinpoint the origin. Also, you can fi lter the oil for patch tests and observe it under a microscope.

Regardless of the waxy material’s origin, there are ways to help prevent it. You should try to minimize crosscontamination among lubricants, assembly oils and additives used in the machine. Take steps to control contaminants in the oil that come from the environment or production processes. Before using an additive or assembly oil, or switching to a synthetic lubricant, ask the lubricant supplier about the potential effects of mixing different products. Also, be sure to limit lubricant contamination with water or process emulsions. In addition, if the equipment must work at low temperatures, verify that the lubricant formulation is appropriate for these operating conditions.

Most likely the waxy residue did not come from a sealant. When a seal or gasket is incompatible with a lubricant, the typical effects are gasket swelling or shrinking but not the generation of wax products.

If you have a question for one of Noria’s experts, email it to editor@noria.com.