Can Defoamant Additives Be Filtered?

The formation of foam is a common problem with lubricants, particularly those with more system turbulence. Foam becomes an issue when it is out of control or when it affects a machine’s operation. For this reason, lubricants are formulated with certain additives known as anti-foam agents or defoamants. These additives are larger in size and may be prone to separation in certain cases. As system cleanliness becomes more stringent, it raises the question of whether these additives can be filtered out of the oil.

What Are Defoamants?

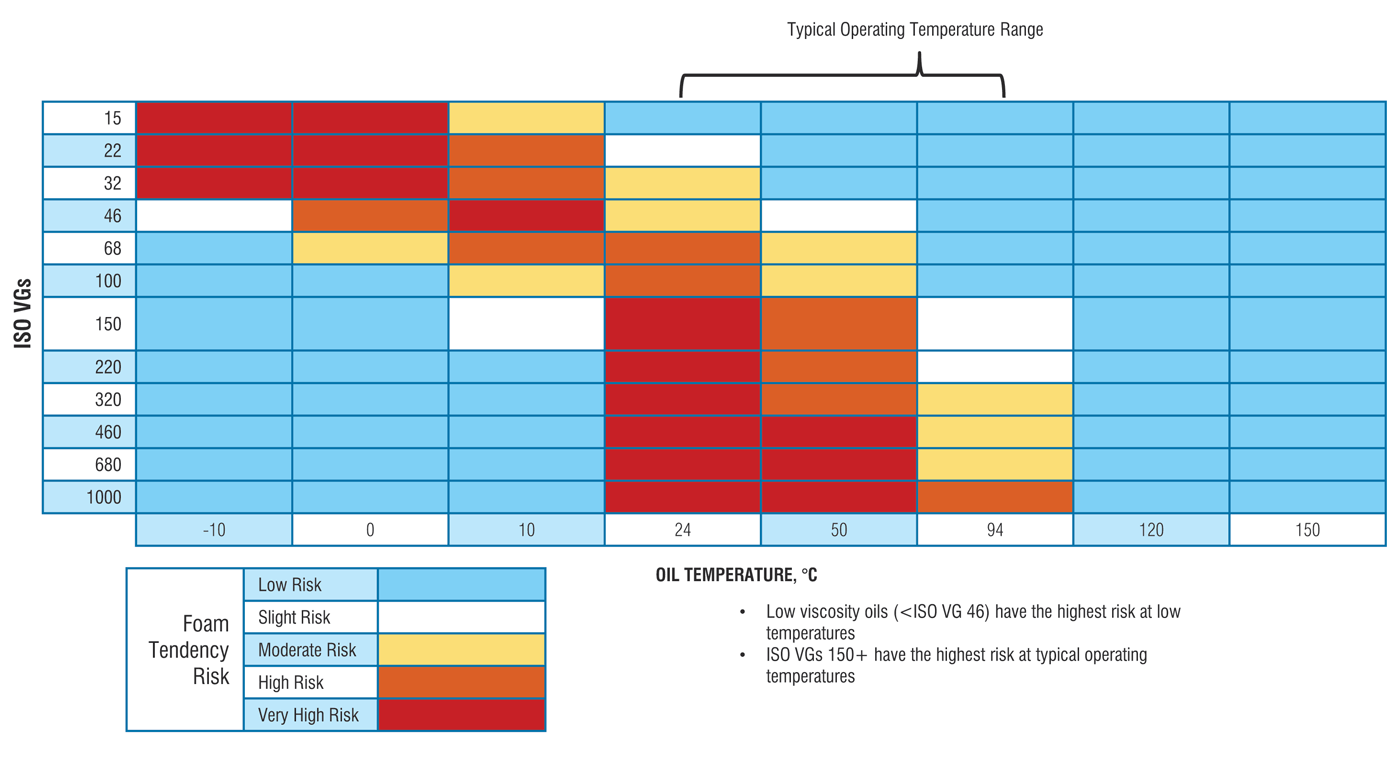

Defoamants primarily exist as one of two chemical compositions: methyl silicone and polymethacrylate. They are blended in oil at different concentrations based on the viscosity and other physical properties of the lubricant in which they are designed to work. Sometimes the application also makes a difference in the type of anti-foam agent to be used. For instance, gear oils with higher viscosities have more of a tendency to foam, due to the likelihood of air bubbles residing in the fluid longer, than a low viscosity turbine oil in which the air bubbles can rise more rapidly, accumulate on the fluid’s surface and break on their own.

Most lubricating oils are formulated with defoamants to minimize the risk of a stable foam occurring on the oil level’s surface. For the lubricant to have the best chance of performing its intended purpose, there must be a delicate balance between defoamants and all other additives blended in the lubricant. If the concentration of defoamants is too low, the machine may experience issues. If the concentration is too high, it could lead to excess foam due to a change in the oil’s surface tension, which impairs the oil’s air-handling characteristics.

How Defoamants Work

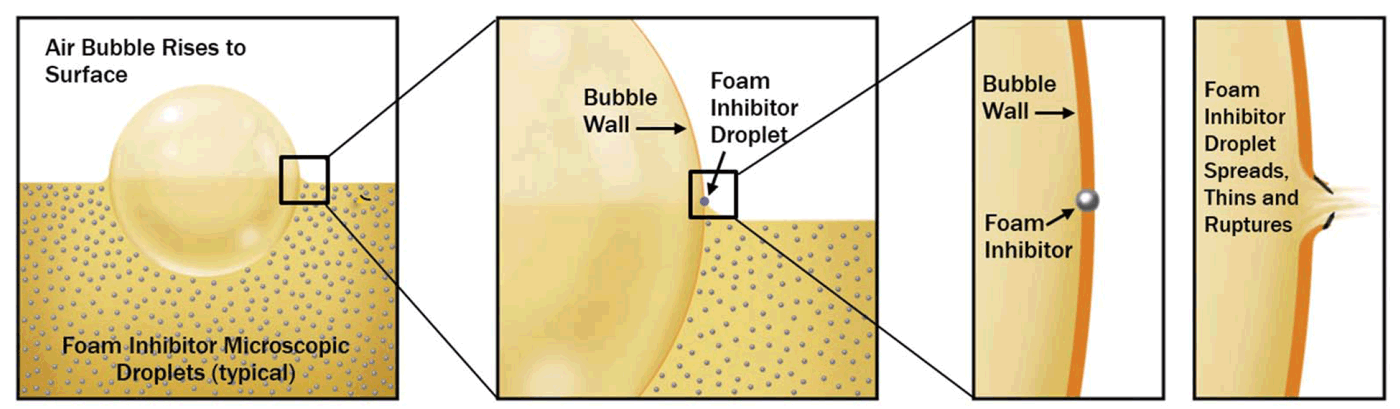

As air becomes entrained in oil, air bubbles attempt to rise to the surface. While a bubble is rising through the oil, it passes through and picks up any number of defoamant additives that are blended into the lubricant. Defoamants are a little different than most additives in that they are suspended in oil rather than dissolved. This is important because defoamants would lose their ability to minimize foam if they were in a dissolved state.

Once an air bubble traps some of these additives in the bubble wall and finally reaches the oil’s surface, the defoamant works to impair the film strength of the bubble wall. Think of it as providing a weak spot in a chain. The interfacial tension of oil is relatively high, but the interfacial tension between the oil and the defoamant droplet is much lower. At this point, the additive spreads and ruptures, allowing air to spill into the atmosphere as the bubble bursts and the stable foam on the oil’s surface is minimized.

In a perfect world, defoamants would do their job, and foam would never be a problem. However, these additives can lose their effectiveness as a result of a number of issues. Perhaps one of the most widespread is the contamination of the oil. Any contaminant that impairs the oil’s surface tension can diminish the performance of the defoamant. Water is one of the most common contaminants that reduces surface tension and leads to excess foaming. Other contaminants include detergents, solvents, fuels and oxidation byproducts. By keeping out contaminants and maintaining clean oil, you can proactively manage foaming.

Another reason defoamants become ineffective is because of their removal from the oil. This can occur due to filtration, which will be discussed later, or from the oil being stored for an extended period of time. Since these additives are suspended and not dissolved, they are prone to settling out of the oil. Without sufficient agitation, defoamants may not fully suspend when the oil is added to a machine, especially if the oil has been in storage for a considerable length of time. This is why performance testing of stored lubricants is highly recommended. It is also one of the many issues that can arise from lubricants exceeding their shelf life in storage.

Why Defoamants Are Needed

In most cases, oils will allow air to separate and keep foam at a manageable level. The problem comes with how quickly this must take place once the lubricant is applied to the equipment. Not all machines have adequate reservoirs to give the lubricant maximum dwell time to cool, shed contaminants and allow entrained air to rise and foam to settle. In fact, many machines don’t have reservoirs, so the oil is in a constant state of turbulence. This is most common in splashlubricated equipment such as pumps and gearboxes. In these applications, the defoamant must keep foam at a minimum so as not to impair lubrication for the rest of the machine.

Machines with circulating oil use defoamants to prevent foam in the reservoir and to reduce air-related issues such as vapor lock in other locations within the lubricant system. These additives greatly increase how fast foam settles and disappears so it doesn’t impair the function or health of the machine in which the lubricant is operating.

Risks Associated with Foam

While a certain amount of foam is acceptable, it can easily get out of control and lead to decreased lubrication. In splash-lubricated machines, excess foam can reduce the oil’s splashing ability and result in lubricant starvation for some components. In circulating systems, foam may restrict the oil’s ability to flow through piping and cause issues such as pump cavitation. Hydraulics may also experience spongy or erratic control if the fluid is foamy.

In terms of lubricant health, foam is detrimental to the overall life of the oil. The most common form of oil degradation is oxidation. Foam has a high percentage of air, which is the chief ingredient in the oxidation process. As foam progresses and limits the equipment’s lubricating tendency, the oil temperature begins to rise. With an increase in operating temperature and plenty of air intermingled in the oil, oxidation occurs at an increased rate. This directly impacts the lubricant’s health and how often the oil must be changed.

There is even some environmental impact associated with excessive foaming. If the oil level cannot be managed, it can lead to spillage as foam seeps out of open hatches, breather ports or seals. The oil then becomes a risk to personnel who could slip, trip or fall. It also becomes a hazard if it gets into a sewer system that is not contained to the plant. If this happens, not only must some type of secondary containment be placed around the machine to contain the spill, but action should be taken to correct the problem causing the foam.

Removal by Filtration

Studies have directly linked lubricant foaming issues with defoamants being stripped due to filtration. Indeed, it is possible to filter out these additives, and if they are no longer in the oil, they will not provide any benefit. Unfortunately, there is not a one-sizefits-all approach to ensure filters aren’t impairing additive levels, since there is variability in the formulation and concentration of defoamants required for equipment.

With standard depth media, there is inconsistency in the filter’s pore sizes. This allows certain additives to make it through while others are removed. Much of this will depend on the filter’s average pore size and how efficient it is at the selected micron size. Some defoamants aren’t solid and can even squeeze through smaller pore sizes.

How to Properly Size Filters

According to filter and lubricant manufacturers, defoamant filtration is most common when oil is “overfiltered” or when the selected filters are too aggressive for the fluid they are charged with decontaminating. While overfiltering can occur, it is rare. Most industrial facilities underfilter their oil or do not filter it at all.

To choose the proper filters for your equipment, you first must set the target cleanliness level. Once the target cleanliness has been set, you can identify a suitable filter to achieve that level. When in doubt, ask the oil or filter manufacturer for specifications.

The general consensus among oil companies is that the biggest risk of filtering out defoamants begins at the 3-micron level. The most widespread application of this type of filtration is in hydraulic and turbine systems, which demand the most stringent cleanliness. Gear systems usually don’t require super-clean fluids and thus don’t need this fine level of filtration. Therefore, it is important not only to consider machine requirements but also the ability to filter oil to this level without damaging additive levels.

How to Monitor

If a defoamant is silicon-based, it can be monitored through normal elemental analysis of the oil sample. When silicon levels drop, you know the additive is being depleted. The best way to monitor organic additives is to conduct performance testing such as the foam stability or foam tendency of the fluid. By comparing these results against new oil, you can judge the additive’s ability and function. Of course, checking for signs of foam in your daily inspection of equipment level gauges will offer the best indication of any potential issues.

Given proper attention and care, defoamants can work well for your equipment and lubricants. Just be sure to size filters accordingly and routinely monitor additive levels to ensure they are working properly and staying healthy.