Understanding and Troubleshooting Hydrostatic Systems

Hydrostatic drives are used in a variety of applications throughout all types of industries. They are sometimes referred to as hydrostatic transmissions. Anytime one or more hydraulic motors need to be driven at variable speeds with bi-directional capability, a hydrostatic drive is often used. Common applications include conveyors, log cranes, mobile equipment, centrifuges, chemi-washers and planers. Hydrostatic drives are some of the least understood systems because many of the components are located on or inside the hydrostatic pump assembly.

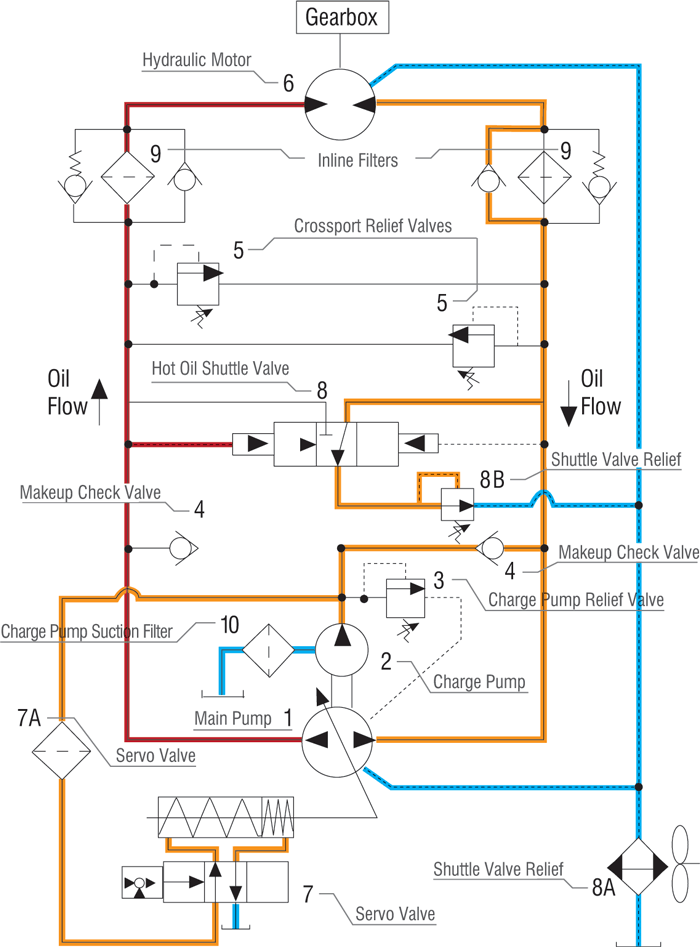

A schematic of a typical hydrostatic drive is shown in Figure 1. The bi-directional, variable displacement pump controls the direction and speed of the hydraulic motor. This type of drive is commonly called a closed-loop system. Notice how the pump’s two ports are hydraulically connected to the two ports on the motor, forming the closed loop.

Main Pump

Main Pump

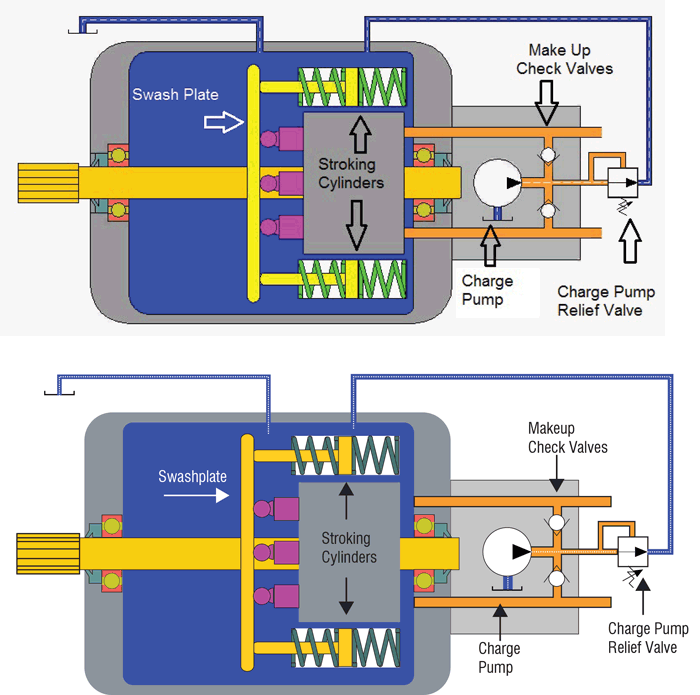

A piston-type pump is always used in a hydrostatic system. The pump volume can range from zero to the maximum amount. In Figure 2, the pump swashplate is in the vertical position, which means the pump output is zero gallons per minute (GPM). The swashplate is moved by two internal cylinders, which are controlled by a separate valve or manual lever.

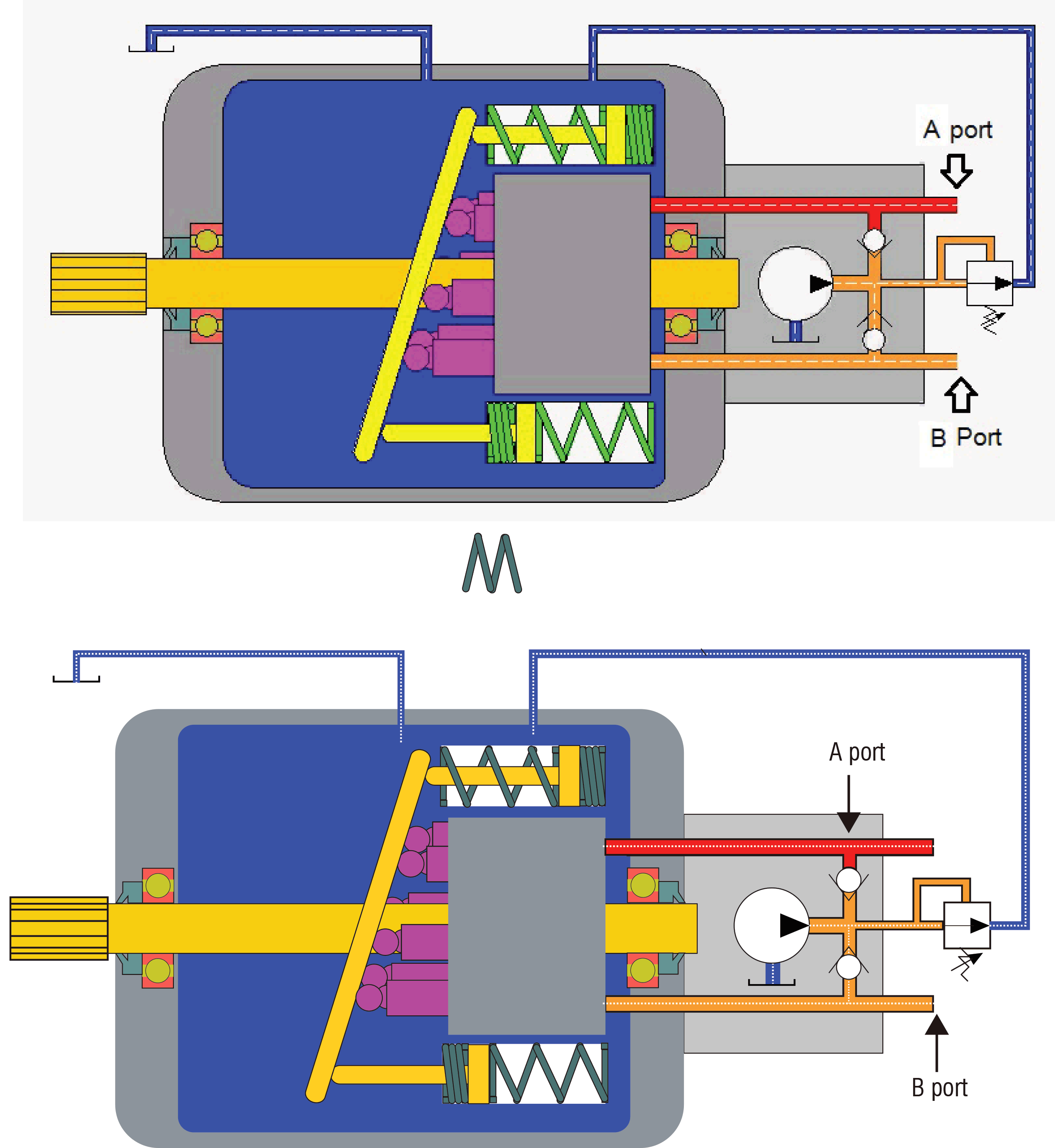

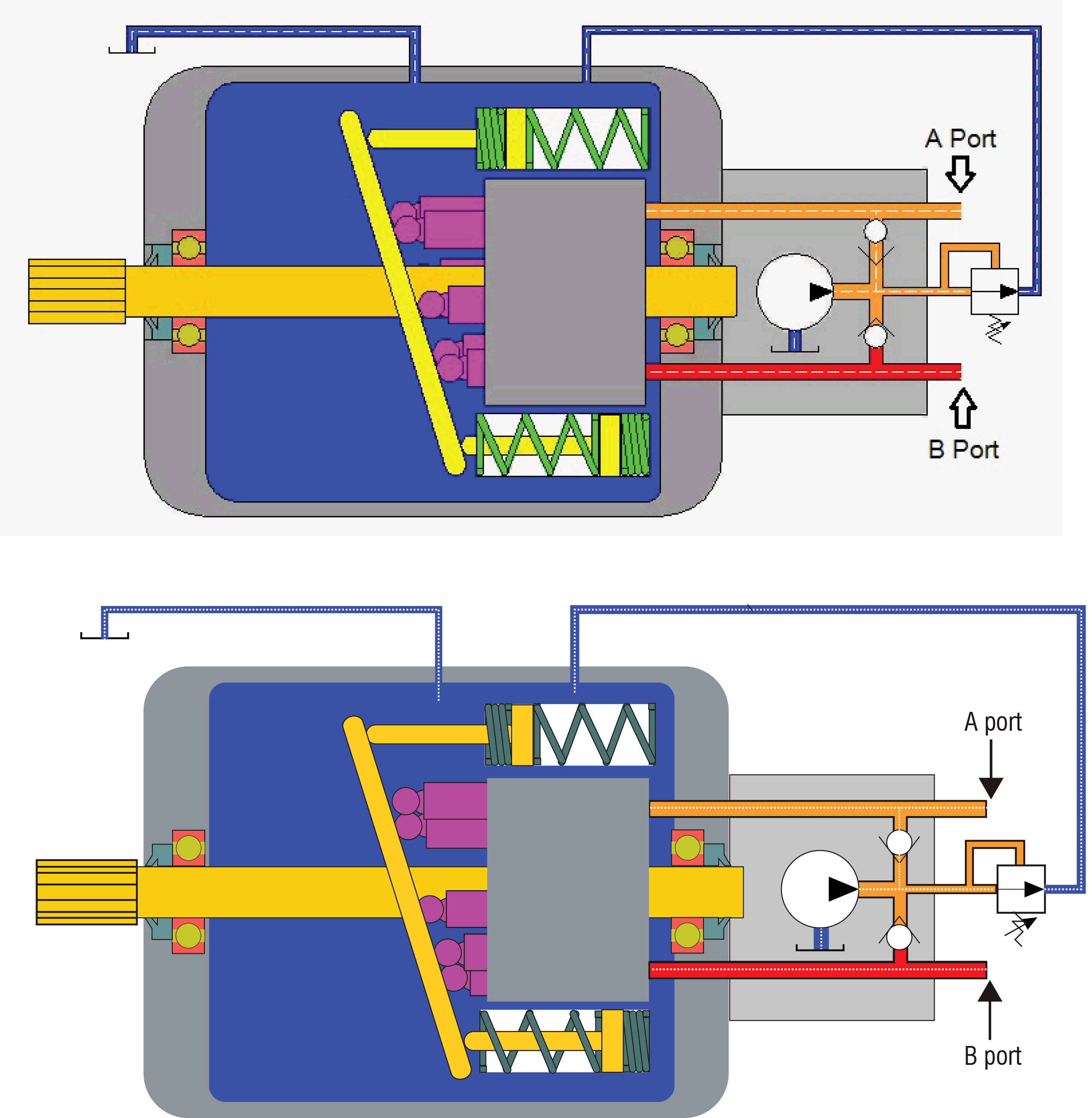

To drive the hydraulic motor forward (Figure 3), the bottom cylinder extends to angle the swashplate and deliver fluid out the “A” port. Oil flow is then directed to the motor for rotating the shaft. As the shaft rotates, the oil that flows out of the motor will return to the “B” port on the pump. This port will act as the suction port in this direction.

To drive the motor in reverse, the top cylinder will extend, allowing the swashplate to angle in the opposite direction (Figure 4). The “B” port will then serve as the pressure port, and the “A” port will be the suction port. The amount the swashplate angles in each direction will determine the flow from the pump.

Charge Pump

A charge pump is mounted on the back end of the main pump. This is sometimes referred to as a replenishing pump. In some cases, the charge pump is located inside the main pump assembly. The charge pump volume is normally 10-15 percent of the main pump volume. When the main pump is in idle mode, the charge pump volume prefills the “A” and “B” ports with fluid. The pressure will continue to build in both ports until the relief valve setting is reached. The charge pump relief is usually set between 200-300 pounds per square inch (PSI). Once the valve’s spring setting is reached, the charge pump volume will flow through the charge pump relief and into the pump case. The oil then returns to the tank through the case drain line.

A charge pump is mounted on the back end of the main pump. This is sometimes referred to as a replenishing pump. In some cases, the charge pump is located inside the main pump assembly. The charge pump volume is normally 10-15 percent of the main pump volume. When the main pump is in idle mode, the charge pump volume prefills the “A” and “B” ports with fluid. The pressure will continue to build in both ports until the relief valve setting is reached. The charge pump relief is usually set between 200-300 pounds per square inch (PSI). Once the valve’s spring setting is reached, the charge pump volume will flow through the charge pump relief and into the pump case. The oil then returns to the tank through the case drain line.

The purpose of the charge pump is to provide makeup fluid to the system during operation. There are tight tolerances between the pistons and the barrel in the pump and motor. This means that some of the oil inside the pump and motor will bypass the pistons and flow back to the tank through the case drain lines. Because of this bypassing, less oil flows out of the motor than what the main pump actually requires. The charge pump will supply makeup oil through the check valve, preventing pump cavitation. The charge pump is also used to supply oil to the spring-loaded cylinders for stroking the main pump.

Charge Pump Relief Valve

Charge Pump Relief Valve

The charge pump relief valve provides a flow path for the excess pump volume to return to the tank in idle mode. The relief valve is normally mounted on or near the charge pump. The outlet flow of this relief valve is usually ported into the pump case where it returns to the tank through the main pump’s case drain line. In the system shown in Figure 2, the relief valve setting determines the pressure in the system when in idle mode. This pressure is typically 200-300 PSI. On systems that utilize a hot oil shuttle valve, a shuttle relief valve determines the pressure on the low side of the loop when driving the motor.

Makeup Check Valves

Makeup check valves permit free flow from the charge pump to the low-pressure side of the loop. At the same time, oil in the high-pressure side is blocked to the low-pressure side by the opposite check valve. The check valves are normally accessed by removing the charge pump.

Crossport Relief Valves

Crossport Relief Valves

Crossport relief valves limit the maximum pressure in the system. If the motor should mechanically stall, the relief valve on the high-pressure side would open and dump fluid back to the low-pressure side of the loop, protecting the motor from overpressurizing. The valves also absorb shock spikes in the system. To best absorb the pressure spikes, the valves are generally mounted as close to the motor as possible. Depending on the system, the valves may be located on the pump, mounted in a separate block or on the hydraulic motor.

The valves typically are preset to 200 to 400 PSI above the maximum operating pressure. Some drives may have a maximum pressure override, which operates similarly to a pump compensator. When the pressure override setting is reached, the pump volume is reduced to an output of nearly zero GPM. The pump will only deliver enough oil to maintain the pressure override setting. On these systems, the pressure override is set below the crossport relief valve settings.

Hydraulic Motor

The speed and direction of the motor is determined by the variable displacement hydraulic pump. Maximum pressure to the motor is controlled by the crossport relief valve settings. The motor case drain flow should be checked and recorded for future troubleshooting purposes. On systems with hot oil shuttle valves, the tank port of the shuttle relief valve is sometimes ported into the hydraulic motor case drain line. With these systems, checking the case flow would not provide an accurate indication of bypassing. This occurs because excess flow in the system would combine with the bypassing in the hydraulic motor.

Regular Maintenance Checks

To effectively troubleshoot a hydrostatic drive, some preliminary checks should be made when the system is operating properly in order to establish a reference.

Record the charge pump relief valve setting. When the main pump is idle, the charge pump relief valve setting will be indicated on all gauges in the system. The exception is when a two-position hot oil shuttle valve is being used.

Record the shuttle relief valve setting. Check this pressure on the low-pressure side of the loop when driving the hydraulic motor.

Record the maximum operating pressure. Check when the drive has the heaviest load on the machine. Check in both forward and reverse directions.

Check the command voltage to the amplifier and the current to the servo valve. The motor’s revolutions per minute should be recorded for a specific DC signal to the servo valve. Speed problems in hydrostatic drives are usually related to either the incoming DC signal or the servo valve. Some pumps have a displacement indicator. The indicator position should also be recorded for a specific command voltage to the amplifier.

If the motor is a piston type, check the case drain flow. As the motor wears, more oil will bypass. Be sure to check when driving the motor, as excessive bypassing occurs when pressure is at the maximum level. This will not be an effective check if the shuttle relief tank line is ported back through the motor case.

Check the filter indicators. Filters typically have a color-coded or other visual indicator to show the element condition. If the elements are partially plugged on non-bypassing-type filters, the drive will slow down. The filters should be checked and changed on a regularly scheduled basis.

Pump Control

The most common method of varying the pump volume is either by a mechanical connection or a servo valve. The mechanical control is done with a cable or other mechanical linkage. In some instances, the mechanical connection shifts a valve on the pump, which ports oil to the spring-loaded cylinders inside the pump. In other cases, the mechanical control is connected directly to the swashplate. An operator will move a joystick or foot pedal to stroke the pump. The gallons per minute the pump delivers are directly proportional to the amount the joystick or pedal is moved. The direction of pump flow and thus the rotation of the hydraulic motor are determined by which direction the pedal or joystick is moved. If the pump is delivering fluid when the joystick or pedal is centered, then the mechanical linkage may need to be adjusted.

Most hydrostatic drives in industrial applications use a servo or proportional valve to control the main pump. The specific valve is usually mounted on the pump housing. The valve is controlled by an input signal into the valve amplifier (normally a positive and negative direct current voltage). The input signal can come from a potentiometer, joystick or programmable logic controller (PLC). A positive voltage generally will shift the valve into the “A” (straight arrows) position, while a negative voltage will shift it into the “B” (crossed arrows) position.

In Figure 1, the servo valve is shifted into the “A” position to port oil from the charge pump to the spring-loaded cylinder for stroking the pump swashplate. Once the swashplate moves proportionally to the amount the servo valve spool shifts, a mechanical feedback will block the oil flow out the servo valve. The pump swashplate will then stop moving and maintain the selected volume. To reverse the flow direction out of the pump, a negative direct current (DC) voltage is applied to the amplifier. The valve will then shift proportionally into the “B” position and deliver fluid out the opposite port to reverse the motor.

When there is no electrical signal to the valve, the pump volume output should be zero GPM. If the hydraulic motor is drifting, either the centering springs on the cylinders need adjusting or the valve needs to be nulled.

The oil flow to the valve is filtered by a non-bypassing 3- to 10-micron element. Most servo valves also contain a small pilot filter that has a 100- to 200-micron rating. If either filter plugs, the pump will stroke very slowly or not at all.

Troubleshooting Hydrostatic Drives

If the neutral position is difficult or impossible to find, check the control valve and linkage. Null the valve if possible.

If the system is overheating, check the oil level in the tank, inspect the heat exchanger, check the inline pressure filters, inspect the crossport relief valves, and check the pump and motor case drains for excessive bypassing.

If the drive only operates in one direction, check the crossport relief valves, the command voltage, the control valve and linkage, and the makeup check valves. Also, inspect the hot oil shuttle valve.

If there is a sluggish response, check the charge pump pressure, charge pump suction filter, charge pump relief valve, hot oil shuttle relief valve, control valve, crossport relief valves, charge pump suction filter and charge pump.

If the drive will not operate in either direction, check the oil in the tank, the control valve and linkage, the command and power supply voltages, the crossport relief valves, the charge pump pressure, the charge pump relief valve, the hot oil shuttle relief valve, the pressure override, and the pump and motor case drain lines for excessive bypassing.

Hot Oil Shuttle Valve and Shuttle Valve Relief

One of the disadvantages of hydrostatic drives is that the majority of the oil stays in the loop and doesn’t return to the reservoir for cooling. One way to return some of the oil back to the tank is by using a hot oil shuttle valve. The purpose of this valve is to direct a portion of the flow exiting the motor through a cooler before returning to the tank.

When the motor is driven in the forward direction, the shuttle valve is shifted so the oil in the suction side of the loop is ported to the shuttle valve relief. The charge pump will deliver more oil to the pump suction side than is needed to make up for the bypassing inside the main pump and motor. This causes the pressure to build up to the shuttle valve relief setting (150-220 PSI). The shuttle relief valve will then open and port a small amount of the oil that flows out of the motor through the cooler and back to the tank. The setting of the shuttle relief valve spring determines the pressure on the low-pressure side of the loop. Although not all systems utilize shuttle valves, they are highly recommended to reduce heat in the system.

It is important that the pressure of the shuttle relief valve be set below the charge pump relief valve. If set higher, the excess charge pump fluid will dump through the charge pump relief valve at all times, bypassing the cooler. This can cause the system to overheat. The hot oil shuttle valve and relief valve generally are bolted onto the hydraulic motor. They may also be mounted in a separate block along with the crossport relief valves.

Inline Filters

The fluid in a hydrostatic loop constantly recirculates, except for the oil flow through the shuttle relief valve. The best filter arrangement is to filter the fluid in both directions on each side of the loop. If filtering is not done in both directions, when the pump fails, the contamination from the pump can go directly into the motor or vice versa.

The fluid in a hydrostatic loop constantly recirculates, except for the oil flow through the shuttle relief valve. The best filter arrangement is to filter the fluid in both directions on each side of the loop. If filtering is not done in both directions, when the pump fails, the contamination from the pump can go directly into the motor or vice versa.

The filters shown in Figure 1 will filter oil as it flows into the motor. If the element becomes contaminated, oil will flow through the spring-loaded bypass check valve. Oil that flows out of the motor will flow through the non-spring-loaded check valve. The filters should have visual or electrical indicators to reveal when the elements are contaminated.

Charge Pump Suction Filter

This filter cleans the oil from the tank to the suction port of the charge pump. It usually is non-bypassing and has a 10-micron rating. The filter should be changed and cleaned on a regular schedule. If it becomes contaminated, the charge and main pump may cavitate.

Hopefully, by learning about the different components of hydrostatic drives, you now have a better understanding of these important systems and how they should function.