Understanding the Rights of Oil Analysis

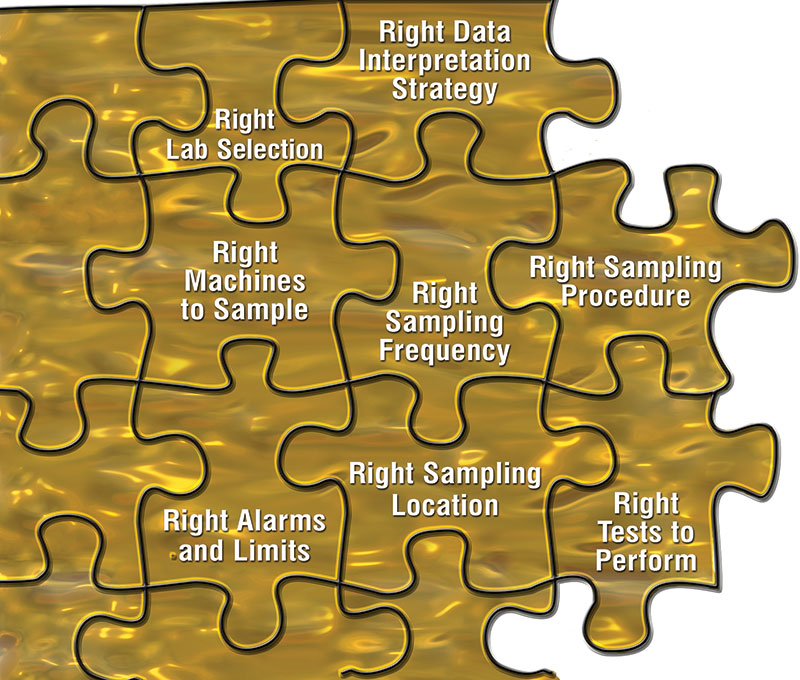

It has been said that oil is the lifeblood of a machine. By monitoring contaminants and additive health, you can keep this “blood” healthy and minimize the risk of a failure. But what are the necessary elements for establishing and maintaining a successful oil analysis program? Consider the eight “rights” of oil analysis.

It has been said that oil is the lifeblood of a machine. By monitoring contaminants and additive health, you can keep this “blood” healthy and minimize the risk of a failure. But what are the necessary elements for establishing and maintaining a successful oil analysis program? Consider the eight “rights” of oil analysis.

Right Lab

You must first decide whether to keep your oil analysis in-house or outsource it. Previously, having an onsite laboratory was cost-prohibitive. As technology has advanced and costs have decreased, this has become a viable option. If an in-house lab is the choice, it is important to select the proper test equipment and to have certified personnel performing the tests. Some organizations use an in-house laboratory for basic tests like viscosity, particle counts and moisture content but utilize an outside lab for exception testing.

If the decision is made to use an offsite laboratory, there are a couple of options to consider. Most lubricant suppliers will provide oil analysis as part of their service offering. The majority of these suppliers have excellent labs with qualified technicians performing the tests. Just be aware of the possibility of allowing the “fox in the henhouse.”

Many laboratories also offer excellent oil analysis services. However, as testing equipment becomes less expensive, a number of labs are springing up with technicians who are not certified and with equipment that may not be correctly calibrated.

Whichever option you choose, I suggest conducting random spot checks of the laboratory. Use blind samples to verify the lab’s accuracy. Send in two samples drawn at the same time from the same reservoir but marked as different pieces of equipment. If the results are not the same, it may indicate that you need a new lab.

Right Test Slate

Frequently, companies enter into a relationship with a laboratory without really knowing what they want. They rely on the lab to steer them in the right direction regarding the tests to run. In some cases, the “standard” test slate may not capture the information needed to make the best maintenance decisions. Therefore, it is imperative to work with your laboratory to determine your individual needs and develop the proper test slate.

Right Sampling Location

It is critical that samples are taken from the proper location, i.e., from a “live zone.” If a sample is drawn just below the surface of the oil in a gearbox, the particle counts will not be very accurate. The same holds true when sampling from a drain plug on the gearbox. Most of the particles will settle to the bottom of the reservoir.

If you have a high particle count when sampling from the top of the reservoir, there is a serious contamination issue. Likewise, if you are sampling from the bottom of the reservoir, you should expect elevated particle counts. Of course, neither of these locations will give you an accurate count of the particles at the gear mesh, which is where the damage is actually occurring.

In a circulating system, samples should be taken at an elbow on the return line prior to the filter. In the gearbox example, I recommend that a minimess sample connection be used in conjunction with a pitot tube to allow samples to be drawn consistently from a location near the gear mesh.

Right Frequency

If you are only sampling your equipment on an annual basis, I would surmise that in most cases this is not enough. Several factors should be considered when determining the sampling frequency such as the age of the equipment, the age of the lubricant, the machine’s criticality, etc.

Right Procedure

You also must ensure that each sample is representative of the fluid in the reservoir and not affected by outside contaminants. A minimess allows a sample to be drawn without opening the reservoir. In addition, by keeping the sample bottle in a plastic bag, you can prevent airborne contaminants from entering the bottle. Drawing a sample from a drain valve with the cap off the bottle enables airborne contaminants to enter the sample. Depending on the environment, this can lead to severely elevated particle counts, essentially rendering the sample useless.

Right Equipment

Sampling equipment should be kept in a clean environment and cleaned after each use and prior to storage. Use minimess sample connections and select sample bottles based on the cleanliness targets. Sample bottles come in three categories: clean, superclean and ultraclean. In every manufacturing process, a certain amount of particles is generated. A bottle’s cleanliness relates to its signal-to-noise ratio. Ultraclean bottles generally are made of glass and are shipped in hermetically sealed vacuum packaging.

Setting Alarms and Limits

The primary purpose for alarms or limits is to filter (funnel) data so that the technologist spends his time managing and correcting exceptional situations instead of laboriously perusing the data trying to find the exceptions. The alarm serves as a “trip-wire” to tell the analyst that a threshold has been passed and that action is required. Some data parameters have only upper limits such as particle counts or wear debris levels. A few data parameters employ lower limits like base number, additive elements, flash point and oxidation stability. Other data parameters like viscosity use both upper and lower limits. These generally relate to important chemical and physical properties of the lubricant where stability of these properties is desired.

Right Alarms and Limits

Many of the plants I visit have robust oil analysis programs. Sadly, several of these programs have improperly set alarms and limits. In the July-August 2011 issue of Machinery Lubrication, Jim Fitch explained how world-class organizations are taking charge of their own alarm settings to ensure that specific objectives are met. He also detailed how the advent of sophisticated oil analysis software has put this objective within reach of most anyone who desires it. To learn more about how to set both proactive and predictive limits for oil analysis, see Setting oil analysis limits.

Right Data Interpretation Strategy

Even if the right lab has been selected, the right test slate is chosen, the right sampling equipment is used, the right procedures are followed and samples are taken from the right location, if you don’t employ the right data interpretation strategy, it is the same as having an all-encompassing encyclopedia and never opening the book. To make the best use of your oil analysis data, you may need to do a bit of homework. Elemental analysis of the lubricant can give you an idea of the composition of the wear metals in a given sample, but if you aren’t familiar with the metallurgy and internal machine configuration, you are likely to suffer some confusion and have to guess as to where the wear material is being generated.

Keep in mind that the rights of oil analysis are all equally important. No one specific right takes precedence over another. Each of these rights must be addressed and applied correctly. Otherwise, your time, effort and money will be wasted. When used properly and combined with other condition monitoring technologies, oil analysis can enable your maintenance program to reach its full potential.