Cavitation or Aeration? How to Tell the Difference

Many maintenance technicians confuse cavitation and aeration. In fact, aeration is sometimes referred to as pseudo cavitation. While these two conditions have similar symptoms, their causes are entirely different.

What Is Cavitation?

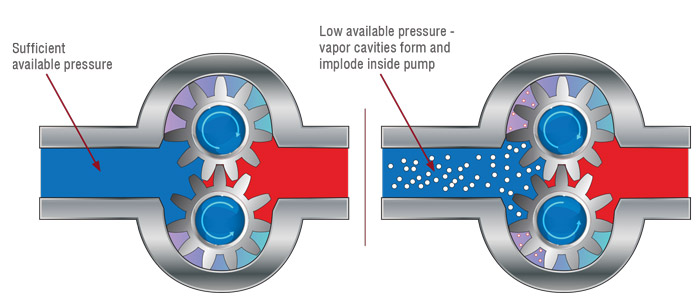

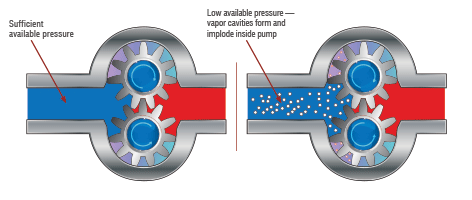

Cavitation is the formation and collapse of air cavities in liquid. When hydraulic fluid is pumped from a reservoir, a low-pressure drop occurs in the suction side of the pump. Despite what many people believe, the fluid is not sucked into the pump but rather pushed into it by atmospheric pressure, as shown in the left illustration below.

The movement of the rotating gears leads to a drop in pressure at the suction line. The resulting pressure difference between the reservoir and the pump inlet causes the fluid to move from the higher pressure to the lower pressure. As long as the pressure difference is sufficient and the flow path is clear, the operation goes smoothly, but anything that reduces the inlet flow can create problems. Whenever the pump cannot get as much fluid as it is trying to deliver, cavitation occurs, as shown in the right illustration below.

Hydraulic oil contains approximately 9 percent dissolved air. When a pump does not get enough oil, air is pulled out of the oil. These air bubbles travel into the pump and eventually collapse and implode when they reach an area of relatively high pressure. The ensuing shockwaves produce a steady, high-pitched whining sound and damage to the inside of the pump.

Causes of Cavitation

Any increase in fluid velocity can lead to cavitation. Fluid velocity is inversely proportional to the size of the hydraulic line. Most pumps have a suction line that is larger than the pressure line. This is to keep inlet velocity low, making it very easy for oil to enter the pump. Any blockage, such as a plugged suction strainer or filter, can result in the pump cavitating. A contaminated suction strainer is the most common cause of cavitation simply because it is underneath the oil level in the reservoir.

One of our consultants was recently called to a plant in Georgia that had changed five pumps on a machine within a week. The first thing that was noticed was a high-pitched whining sound, which was heard every 20 to 30 seconds. The millwrights had changed the suction line, and although a suction strainer was shown on the schematic, none was found in the line. The machine was then shut down, and the reservoir drained to be cleaned. Guess what was found in the reservoir? The suction strainer, which had been floating around in the oil, was occasionally blocking the suction pipe to the pump.

A plugged breather cap is another common cause of cavitation. It can lead to falling pressure in the reservoir. Suction pressure at the pump must drop very low to compensate for this, creating vapor cavities.

At a plywood plant in Oregon, a hose ruptured on the lathe, which resulted in a loss of 150 gallons of oil in the reservoir. After the hose was changed, the lubrication technician removed one of the breather caps to refill the reservoir. While filling the tank, a shift change occurred, and the second-shift lube tech took over. Once the reservoir was refilled, the lube tech installed a pipe plug on the threads where the breather cap was originally located. The result was that one of the pumps on the unit failed within a few hours after startup due to cavitation. After losing two pumps in 24 hours, the pipe plug on the breather opening was discovered.

Extreme oil temperatures can also cause cavitation. High temperatures allow vapor cavities to form with less of a pressure drop, while low temperatures increase the oil’s viscosity, making it harder for the oil to get into the pump. Most hydraulic systems should not be started up with the oil any colder than 40 degrees F or put under load until at least 70 degrees F.

In addition, cavitation may result if the drive speed is too high for the pump, as the pump tries to deliver more oil than it can get into its suction port. If the pump is positioned so fluid must be lifted a long way from the reservoir, atmospheric pressure may be insufficient to deliver enough fluid to the pump inlet, which can cavitate.

Systems at high altitudes are also susceptible to cavitation, as the available atmospheric pressure may be inadequate. It is for this reason that aeronautic hydraulics must use pressurized reservoirs.

Understanding Aeration

Aeration occurs whenever outside air enters the suction side of the pump. This produces a sound that is more erratic than that of cavitation. The whining noise may be augmented by a sound similar to marbles or gravel rattling around inside the pump. If the oil in the reservoir is visible, you may see foaming. Air in the oil can lead to sluggish system performance and even damage the pump and other components.

Aeration occurs whenever outside air enters the suction side of the pump. This produces a sound that is more erratic than that of cavitation. The whining noise may be augmented by a sound similar to marbles or gravel rattling around inside the pump. If the oil in the reservoir is visible, you may see foaming. Air in the oil can lead to sluggish system performance and even damage the pump and other components.

Causes of Aeration

Aeration is often caused by an air leak in the suction line. Pressure in the suction line is below that of atmospheric pressure, so if there’s a leak in the suction line, oil won’t leak out, but air will leak in. If you suspect an air leak, put oil on all the fittings and connections in the suction line. If the sound of aeration stops briefly, you have found your leak. An ultrasonic gun can also be used to detect leaks.

One of our consultants was asked to diagnose several pump failures on a system at an automotive manufacturing plant. When he arrived at the unit, he heard an erratic high-pitched sound. He also noticed that there were several fittings in the suction line. He had one of the millwrights fill a bottle with oil and squirt it around all the fittings. When oil was applied to one fitting, the pump momentarily quieted down. This fitting had vibrated loose after 12 years on the machine.

A bad shaft seal on a fixed displacement pump is another common cause of aeration. If you suspect a bad shaft seal, spray some shaving cream around the seal. If it is bad, holes in the shaving cream will develop as air enters the pump.

I was once called to a paper mill where foam came out of the log-kicker reservoir shortly after the fixed displacement pump was started. After performing the shaving cream test, I knew the shaft seal was badly worn. Upon further inspection, I found the pump elastomeric coupling was worn, which resulted in wear on the shaft seal.

Improperly tightened or aligned fittings in the suction line can also cause aeration. Check all the fittings and make sure they are torqued and aligned according to specifications.

Incorrect shaft rotation may not be an issue with all pumps, but some will aerate if they are turned backward. Most pumps have a direction of rotation stamped or located on a sticker on the pump housing. Many times when a pump is rebuilt, this sticker is removed. Always check the part number of the new pump to be installed with the old pump. Often a number or letter will indicate whether it is a right-hand or left-hand rotation. If you are unsure, remove the pump’s outlet line and secure it into a container. Never hold this line, as it could be a hazardous situation. Momentarily jog the electric motor. If the pump is rotating in the correct direction, oil will flow out of the outlet port.

Aeration may also result from a low fluid level. The oil level should never drop more than 2 inches above the suction line. If so, a vortex can form, much like when draining a bathtub. This allows air in the suction line, leading to aeration of the pump.

When troubleshooting hydraulic pump issues, make the visual and sound checks first, as these are the easiest to perform. Remember, aeration and cavitation produce different sounds. Usually you can determine the cause of the problem before the first wrench is turned.

Many maintenance technicians confuse cavitation and aeration. In fact, aeration is sometimes referred to as pseudo cavitation. While these two conditions have similar symptoms, their causes are entirely different.

What Is Cavitation?

Cavitation is the formation and collapse of air cavities in liquid. When hydraulic fluid is pumped from a reservoir, a low-pressure drop occurs in the suction side of the pump. Despite what many people believe, the fluid is not sucked into the pump but rather pushed into it by atmospheric pressure, as shown in the left illustration below.

The movement of the rotating gears leads to a drop in pressure at the suction line. The resulting pressure difference between the reservoir and the pump inlet causes the fluid to move from the higher pressure to the lower pressure. As long as the pressure difference is sufficient and the flow path is clear, the operation goes smoothly, but anything that reduces the inlet flow can create problems. Whenever the pump cannot get as much fluid as it is trying to deliver, cavitation occurs, as shown in the right illustration below.

Hydraulic oil contains approximately 9 percent dissolved air. When a pump does not get enough oil, air is pulled out of the oil. These air bubbles travel into the pump and eventually collapse and implode when they reach an area of relatively high pressure. The ensuing shockwaves produce a steady, high-pitched whining sound and damage to the inside of the pump.

Causes of Cavitation

Any increase in fluid velocity can lead to cavitation. Fluid velocity is inversely proportional to the size of the hydraulic line. Most pumps have a suction line that is larger than the pressure line. This is to keep inlet velocity low, making it very easy for oil to enter the pump. Any blockage, such as a plugged suction strainer or filter, can result in the pump cavitating. A contaminated suction strainer is the most common cause of cavitation simply because it is underneath the oil level in the reservoir.

One of our consultants was recently called to a plant in Georgia that had changed five pumps on a machine within a week. The first thing that was noticed was a high-pitched whining sound, which was heard every 20 to 30 seconds. The millwrights had changed the suction line, and although a suction strainer was shown on the schematic, none was found in the line. The machine was then shut down, and the reservoir drained to be cleaned. Guess what was found in the reservoir? The suction strainer, which had been floating around in the oil, was occasionally blocking the suction pipe to the pump.

A plugged breather cap is another common cause of cavitation. It can lead to falling pressure in the reservoir. Suction pressure at the pump must drop very low to compensate for this, creating vapor cavities.

At a plywood plant in Oregon, a hose ruptured on the lathe, which resulted in a loss of 150 gallons of oil in the reservoir. After the hose was changed, the lubrication technician removed one of the breather caps to refill the reservoir. While filling the tank, a shift change occurred, and the second-shift lube tech took over. Once the reservoir was refilled, the lube tech installed a pipe plug on the threads where the breather cap was originally located. The result was that one of the pumps on the unit failed within a few hours after startup due to cavitation. After losing two pumps in 24 hours, the pipe plug on the breather opening was discovered.

Extreme oil temperatures can also cause cavitation. High temperatures allow vapor cavities to form with less of a pressure drop, while low temperatures increase the oil’s viscosity, making it harder for the oil to get into the pump. Most hydraulic systems should not be started up with the oil any colder than 40 degrees F or put under load until at least 70 degrees F.

In addition, cavitation may result if the drive speed is too high for the pump, as the pump tries to deliver more oil than it can get into its suction port. If the pump is positioned so fluid must be lifted a long way from the reservoir, atmospheric pressure may be insufficient to deliver enough fluid to the pump inlet, which can cavitate.

Systems at high altitudes are also susceptible to cavitation, as the available atmospheric pressure may be inadequate. It is for this reason that aeronautic hydraulics must use pressurized reservoirs.

Understanding Aeration

Aeration occurs whenever outside air enters the suction side of the pump. This produces a sound that is more erratic than that of cavitation. The whining noise may be augmented by a sound similar to marbles or gravel rattling around inside the pump. If the oil in the reservoir is visible, you may see foaming. Air in the oil can lead to sluggish system performance and even damage the pump and other components.

A fitting (marked “A”) on this hydraulic pump suction

line vibrated loose after 12 years, leading to aeration.

Causes of Aeration

Aeration is often caused by an air leak in the suction line. Pressure in the suction line is below that of atmospheric pressure, so if there’s a leak in the suction line, oil won’t leak out, but air will leak in. If you suspect an air leak, put oil on all the fittings and connections in the suction line. If the sound of aeration stops briefly, you have found your leak. An ultrasonic gun can also be used to detect leaks.

One of our consultants was asked to diagnose several pump failures on a system at an automotive manufacturing plant. When he arrived at the unit, he heard an erratic high-pitched sound. He also noticed that there were several fittings in the suction line. He had one of the millwrights fill a bottle with oil and squirt it around all the fittings. When oil was applied to one fitting, the pump momentarily quieted down. This fitting had vibrated loose after 12 years on the machine.

A bad shaft seal on a fixed displacement pump is another common cause of aeration. If you suspect a bad shaft seal, spray some shaving cream around the seal. If it is bad, holes in the shaving cream will develop as air enters the pump.

I was once called to a paper mill where foam came out of the log-kicker reservoir shortly after the fixed displacement pump was started. After performing the shaving cream test, I knew the shaft seal was badly worn. Upon further inspection, I found the pump elastomeric coupling was worn, which resulted in wear on the shaft seal.

Improperly tightened or aligned fittings in the suction line can also cause aeration. Check all the fittings and make sure they are torqued and aligned according to specifications.

Incorrect shaft rotation may not be an issue with all pumps, but some will aerate if they are turned backward. Most pumps have a direction of rotation stamped or located on a sticker on the pump housing. Many times when a pump is rebuilt, this sticker is removed. Always check the part number of the new pump to be installed with the old pump. Often a number or letter will indicate whether it is a right-hand or left-hand rotation. If you are unsure, remove the pump’s outlet line and secure it into a container. Never hold this line, as it could be a hazardous situation. Momentarily jog the electric motor. If the pump is rotating in the correct direction, oil will flow out of the outlet port.

Aeration may also result from a low fluid level. The oil level should never drop more than 2 inches above the suction line. If so, a vortex can form, much like when draining a bathtub. This allows air in the suction line, leading to aeration of the pump.

When troubleshooting hydraulic pump issues, make the visual and sound checks first, as these are the easiest to perform. Remember, aeration and cavitation produce different sounds. Usually you can determine the cause of the problem before the first wrench is turned.