A New Approach for Determining the Acid and Base Number of Used Oils

The acid number and base number of in-service oils are considered key indicators of oil quality and are used to monitor the accumulation of acid and the depletion of the base additive package. A significant rise in acid number or decrease in base number may reflect a deterioration in oil quality either due to chemical reactions, oxidation, incorrect oils, additive depletion and contamination. Tables 1 and 2 summarize common acid number and base number methods.

ASTM methods, including D664, D974, D2896 and D4739, are the current industry standard methods for measuring the acid and base number. These titration-based methods are slow and expensive to execute, require significant volumes of sample and solvent, and are prone to interferences. As a result, these methods have relatively wide repeatability and reproducibility limits, accounting for their significant inter-laboratory variability. The high cost and poor accuracy of these methods limit their usefulness and application to routine oil monitoring.

The acid number and base number are also sometimes reported using a variety of partial least squares (PLS) direct-read Fourier transform infrared (FTIR) methods, which estimate the acid and base number of used oils by directly measuring the spectrum of undiluted oil.

uantitative FTIR Spectroscopy

uantitative FTIR Spectroscopy

FTIR spectroscopy has been touted as a potential alternative means of obtaining quantitative acid number and base number data. However, there previously had been no solid evidence that FTIR was viable or reliable in commercial practice. FTIR has predominantly been utilized as an automated fingerprint-based survey technique, as per ASTM D7418-07 or the Joint Oil Analysis Program, which is typically used for screening and trending changes in lubricant parameters such as moisture, glycol, soot, oxidation, antioxidants and wear additives. As such, FTIR condition monitoring analysis provides a rapid, automated means of screening a large number of oil samples, in part to determine if additional quantitative analyses, such as acid or base number determinations, are required.

Types of FTIR Calibrations

Currently, there are three distinct quantitative approaches available for acid number or base number analysis by FTIR. One is based on direct neat-oil analysis solely using partial least squares (PLS) chemometrics. Another is based on the use of ASTM-like acid/base stoichiometric reactions. A third approach, called a mixed-mode calibration, combines the advantages of both the PLS and stoichiometric calibrations.

PLS-only Calibrations

A PLS-only calibration is created by comparing ASTM D664 and D4739 data to the undiluted FTIR spectra of a representative set of in-service oils. Partial least squares is then used to correlate variations in these spectra to the acid number and base number results measured by titration. The spectrum of unknown samples can then be used to predict or estimate the acid number or base number result.

PLS-based spectral methods rely solely on non-specific spectral changes that can become problematic when dealing with used oil samples because they have significant and tricky interferences that can be difficult to model adequately. These older direct-read methods have trouble accounting for real-life variables such as soot, water, incorrect lubricant or mixtures of lube and oil degradation products.

| Acid Number Method | Type | Reagent | Calibration | Notes |

|---|---|---|---|---|

| ASTM D664 | Titration | Potassium hydroxide | Stoichiometric | Slow, high uncertainty |

| ASTM D974 | Titration | Potassium hydroxide | Stoichiometric | Dark oils interfere with measurement |

| PLS-FTIR | FTIR direct read | None | PLS calibration | Subject to interferences |

| Stoichiometric-FTIR | FTIR acid/base reaction based | IR active base | PLS and stoichiometric | Improved precision over ASTM D664 |

| Base Number Method | Type | Reagent | Calibration | Notes |

|---|---|---|---|---|

| ASTM D2896 | Titration | Perchloric acid in glacial acetic acid | Stoichiometric | Slow, labor-intensive, used for new oil quality control |

| ASTM D4739 | Titration | Hydrochloric acid | Stoichiometric | Slow, high uncertainty |

| PLS-FTIR | FTIR direct read | None | PLS calibration | Subject to interferences |

| Stoichiometric-FTIR | FTIR acid/base reaction based | IR active acid | PLS and stoichiometric | Improved precision over ASTM D4739 |

| FTIR Calibration Type | Calibration Samples | Notes |

|---|---|---|

| PLS (partial least squares) | In-service oil samples with corresponding ASTM acid number or base number data | • Fast analysis

• Easy-to-set-up calibration • Subject to interferences • Estimate ASTM D664 and D4739 |

| Stoichiometric – linear fit | Gravimetrically prepared standards of organic acid/base diluted in mineral oil | • Accurate and precise

• Calibration is anchored to stoichiometric chemical reactions • Results cannot be directly compared to ASTM D664 or D4739 |

| Mixed mode = PLS + stoichiometric | Gravimetrically prepared standards and samples of used oil with corresponding ASTM D664 or D4739 data | • Results are a direct match to

ASTM D664 and D4739/D2896

• Accurate and precise • High initial development cost |

Stoichiometric Calibrations

The stoichiometric calibration relies on acid/base reactions that are directly measured using the absorbance of infrared light. This is made possible through the use of weaker but “IR active” organic acids and bases rather than stronger inorganic potassium hydroxide (KOH) or hydrochloric acid (HCl), as per ASTM methods. With this approach, the analytical principles are similar to the ASTM methods, e.g., acid/base reactions, but instead of titrating to determine the end point, the acid/base reaction is monitored and measured spectrally.

One of the consequences of using weaker organic acids and bases is that the predicted analytical FTIR acid number/base number values obtained will be significantly lower than those obtained using the titration methods. Until recently, this divergence of FTIR acid number and base number values from those obtained using titration procedures was a major impediment to laboratories wishing to make use of the stoichiometric approach. Oil analysis and reliability clients are naturally reluctant to change their familiar analytical frame of reference, and a shift in expected acid number and base number values could lead to confusion. This problem was solved by the development of a “mixed-mode” stoichiometric calibration with the concurrent implementation of PLS.

| ASTM D664 | FTIR Acid Number | ASTM D4739 |

FTIR Base Number |

|

|---|---|---|---|---|

| Sample preparation time | 120 seconds per sample | 60 seconds per sample | 120 seconds per sample |

120 seconds per sample# 60

seconds per sample |

| Samples per hour | 4-6 | 60 | 4-6 |

60 |

| Daily startup and preventative maintenance time | Variable (up to 1 hour) | < 15 minutes | Variable (up to 1 hour) | < 15 minutes |

| Waste disposal volume | ~130 ml | ~25 ml | ~90 ml | ~25 m |

| Base Number | Mixed-Mode Base Number FTIR Reproducability | ASTM D4739 Reproducability | Acid Number | Mixed-Mode Acid Number FTIR Reproducability | ASTM D664 Reproducability |

|---|---|---|---|---|---|

| 6 | 1.3 | 3.55 | 1 |

0.20 |

0.44 |

| 10 | 1.3 | 4.52 | 2 |

0.20 |

0.88 |

| 15 | 1.3 | 5.46 | 3 |

0.20 |

1.32 |

Mixed-mode Calibrations

The mixed-mode method combines the advantages of both types of FTIR calibration. This calibration is anchored using gravimetrically prepared ideal standards to define the fundamental acid/base relationship. Hundreds of in-service oil samples are then used to further account for the spectral variability induced by real samples and to align the data with the corresponding ASTM method. PLS serves only to refine the measurement and to ensure that the results match the ASTM reference method used in its development.

A variety of mixed-mode PLS calibrations were recently developed and assessed. The bulk of the samples analyzed for the PLS component of the base number calibration were in-service engine oils covering most major lubricant suppliers and representing a wide range of equipment applications (mining, transport, generators, marine, etc.), with nearly 70 percent using diesel fuel and the balance natural gas. In the case of acid number, a mix of new and in-service oils covering a wide range of suppliers and grades was considered, including oils from engines, compressors, hydraulic systems, turbines, transmissions and gearboxes.

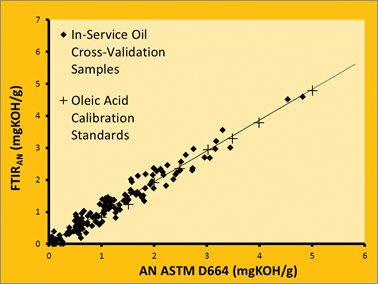

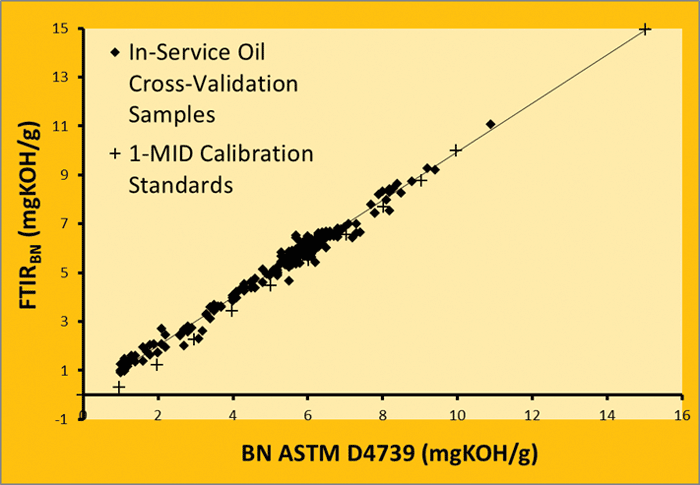

Figure 2. A cross-validation chart of the mixed-mode calibration comparing acid number data for in-service oil samples analyzed by ASTM D664 and the FTIR acid number method Figure 3. A cross-validation chart of the mixed-mode calibration comparing base number data for in-service oil samples analyzed by ASTM D4739 and the FTIR base number method Figures 2 and 3 illustrate the typical cross-validated FTIR calibrations obtained for acid number and base number, respectively.

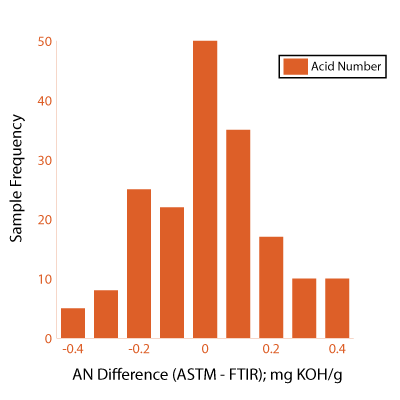

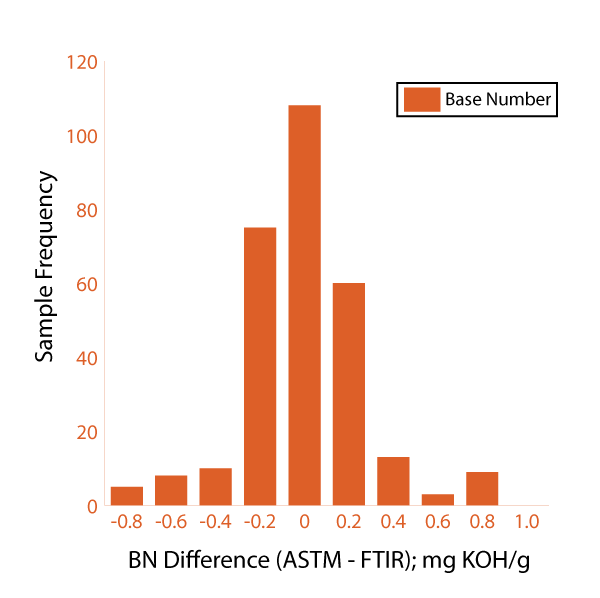

The performance of the mixed-mode calibrations was monitored over a six-month period. Some 177 acid number samples and 284 base number samples were analyzed using both the FTIR method and the corresponding ASTM titration methods (D664 and D4739). Samples included a mixture of new and used oils from a wide variety of components, including hydraulic systems, gearboxes, transmissions, engines, turbines and compressors.

Figures 4 and 5 show the differences between the individual ASTM and FTIR results for acid number and base number, respectively. The analytical differences between the two methods are normally distributed in both cases, with each having an overall mean difference of almost zero. This indicates on-average similarity in their results, with the variability around the mean difference reflecting the reproducibility of the ASTM reference methods. These extended production results clearly demonstrated that the FTIR acid number/base number methods are capable of delivering ASTM-identical results.

FTIR Calibration Pros and Cons

Based on the recent two-year assessment, the mixed-mode calibration can deliver statistically ASTM-identical data at rates roughly equivalent to operating nine to 10 dedicated titrators for each analysis type. Tables 4 and 5 summarize and compare the key variables of the two analytical approaches (ASTM and FTIR). With one analyst capable of analyzing nearly 500 samples by FTIR per 8-hour shift, the advantage is clearly in favor of the FTIR system.

Although the mixed-mode calibration was developed to produce results statistically identical to ASTM D664 and D4739, accuracy is intrinsically limited by the uncertainty of these reference methods. The uncertainty and bias in the FTIR methods can be minimized by using a large set of in-service oil samples (more than 200). The FTIR methods also benefit from excellent precision in contrast to the more complicated indirect titration-based methods.

While the stoichiometric approach was found to be superior in accuracy relative to the neat-oil PLS-only approach, this does not mean the PLS-only method should be completely discounted as a potentially useful procedure. It is possible that this method may serve to provide adequate tracking estimates of ASTM parameters in more limited situations. Unfortunately, there is no published information or performance data available for the chemometric PLS-only approach. The advantage of this method is that it can make use of FTIR instrumentation that many laboratories already have in place.

Neither the FTIR PLS-only nor the stoichiometric acid number/base number approaches are sanctioned by any governing bodies, ASTM or otherwise. Therefore, any laboratory using either of these methods can only present the results to their clients as an accurate, precise and cost-effective means of obtaining acid and base number data.