Lube-Tips

Tip for Replacing Oil Filters

Tip for Replacing Oil Filters

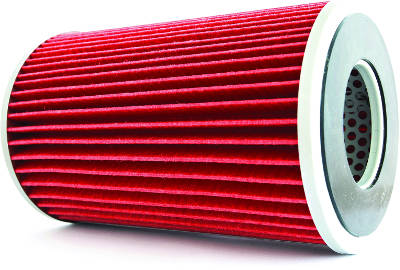

When replacing top-suspended spin-on or threaded canister-type filters, fill them with fresh oil before installation. This will reduce the amount of time that the engine or machinery undergoes dry start-up by having an extra amount of oil available. In some cases, it could also prevent filter damage when a gush of high-pressure fluid hits a dry element

How to Speed up Oil Changes

Use your circulation pump to speed up oil changes in large circulation systems. Install a tee and two isolating shut-off valves downstream of your circulating pump. When draining your reservoir, connect the hose to this tee and use your pump to move the oil from your reservoir to the scrap oil truck. This is especially helpful for large, below-ground level systems

Pay Attention to Your Oil Level Indicator

Pay Attention to Your Oil Level Indicator

When rolling-element bearings are lubricated from oil held in a sump, attention to the oil sump level indicator will not only bring savings in terms of extended bearing life, but also will lead to reduced bearing temperatures due to churning and metal-to-metal contact resulting from possible oil starvation. As a general rule, the lowest rolling element should be half covered with oil when the bearing is stationary. This may seem like a simple rule to observe, but it is surprising how often it is completely overlooked.

Did You Know?

Additional tips can be found in our Lube-Tips email newsletter. To receive the Lube-Tips newsletter, subscribe now at MachineryLubrication.com

If you have a tip to share, email it to editor@noria.com.