Lube-Tips

The “Lube-Tips” Section of Machinery Lubrication magazine features innovative ideas submitted by our readers. additional tips can be found in our Lube-Tips email newsletter. if you have a tip to share, email it to editor@noria.com. To receive the Lube-Tips newsletter, subscribe now at www.machineryLubrication.com/page/subscriptions.

Sampling Refrigeration Compressor Oils

When sampling refrigeration compressor oils, particularly some synthetics such as polyalkylene glycols (PAGs) and polyolesters (POEs), it is of paramount importance that the lubricant is exposed to the air for as little time as possible. This applies particularly in humid environments. The reason for this is that these lubricants are hygroscopic, which means they absorb uncondensed water vapor directly from humid air. An accurate moisture content reading is vital for the analysis of most refrigerant system lubricants. It is for this reason that the lubricant should be given as little exposure to the atmosphere as possible. Likewise, it is important that your laboratory take equal care not to expose the oil to the air when it carries out its tests. Ideally, the moisture content test should be the frst one performed.

When sampling refrigeration compressor oils, particularly some synthetics such as polyalkylene glycols (PAGs) and polyolesters (POEs), it is of paramount importance that the lubricant is exposed to the air for as little time as possible. This applies particularly in humid environments. The reason for this is that these lubricants are hygroscopic, which means they absorb uncondensed water vapor directly from humid air. An accurate moisture content reading is vital for the analysis of most refrigerant system lubricants. It is for this reason that the lubricant should be given as little exposure to the atmosphere as possible. Likewise, it is important that your laboratory take equal care not to expose the oil to the air when it carries out its tests. Ideally, the moisture content test should be the frst one performed.

Advice for Sight Glass Inspections

If there is a sight glass for the reservoir of your bearing lubricant, make sure there is a line that marks the level of the lubricant when the bearing is running and a line that marks the level of the lubricant when the bearing is stationary.

Timing Diesel Engine Oil Changes

Users of large diesel engines should consider changing oil and oil sampling based on the gallons of fuel burned versus calendar or work hours of the driver. The driver may not actually drive all the hours for which he is paid. Likewise, some days using the calendar method will be weekends and holidays.

Filter Change Tip

When changing a flter element inside a housing, drain all the oil from the flter housing frst. There should be a drain port near the bottom of the housing as well as a port on the top to let in air. This procedure will eliminate debris that was trapped in the flter element from rinsing out when pulled through the oil in a flled housing. This debris will get a free run at your system when restarted because it is already on the downstream side of the new flter.

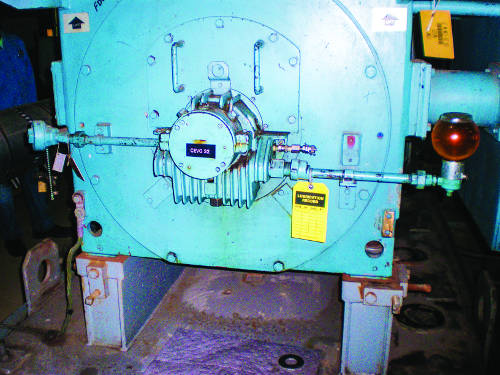

How to Take Care of Idle Machinery

If electric motors are to be stored for a period of time, the vibrations created by the plant could cause false brinelling of the bearings. False brinelling occurs when the protective flm of a lubricant is worn away by vibration and there is metal-to-metal contact between the edge of the rolling element and the bearing race. To prevent false brinelling, turn the shaft of the stored motor with your fngers a minimum of once a month. The same principle applies to idle machinery. The idle machine needs to be “bumped” to ensure that there is a flm of the lubricant between the rolling element and the race.

Avoiding Bearing Contamination

Most large motors that have bearings with oil reservoirs are topped off through pipe plugs located on the top of the bearing housing. The problem is that as the top-off oil is added to the reservoir, it frst passes over the threads for the pipe plug, washing any dirt, metal or other contaminants into the reservoir. To cure this, try screwing a short pipe nipple into the opening and capping it off with a pipe cap. Now when oil is added, it no longer passes over the active threaded area, helping to keep your top-off oil contaminant-free.