Ask the Experts

“Which would be the best application of oil: an oil lifter (ring and collar) or oil circulation in a ventilator (large roller bearing with medium speed)?”

Oil application methods vary based on a number of variables such as speed, size, lubricant viscosity and ambient conditions. You must match the lubricant delivery mechanism with how the machine is expected to operate. Otherwise, large amounts of wear can be generated, causing downtime and potentially excess energy consumption.

Oil application methods vary based on a number of variables such as speed, size, lubricant viscosity and ambient conditions. You must match the lubricant delivery mechanism with how the machine is expected to operate. Otherwise, large amounts of wear can be generated, causing downtime and potentially excess energy consumption.

It is important to understand the benefits and weaknesses of each method. Oil lifting devices are among the oldest lubricant delivery mechanisms. They utilize the machine’s rotational movement to pick up oil and transport it to the component that needs to be lubricated.

The biggest difference between a ring oiler and a collar oiler is how it is affixed to the shaft. Ring oilers are not attached to the shaft but simply ride on it (sometimes in grooves) and lift the oil where it needs to go. Collar oilers are firmly attached to the shaft and rotate with it accordingly. Both ring oilers and collar oilers must operate at a defined shaft speed and be sized appropriately to lift the proper oil volume to lubricate the machine.

While these devices are simple and generally require little maintenance, there are some inherent drawbacks in their use. Perhaps the biggest potential problem involves insufficient oil levels. The oil level inside the machine must be continually inspected to ensure the lifting device can function properly. An oil level that is slightly too high or too low can greatly impact the effectiveness of these devices.

In cold conditions, there is also a risk of channelling, which means the lubricant viscosity is too high to be lifted. During start-ups and shut-downs, rings and collars may simply not lift enough oil to lubricate the machine. This can lead to boundary conditions and increased wear of the internal machine parts.

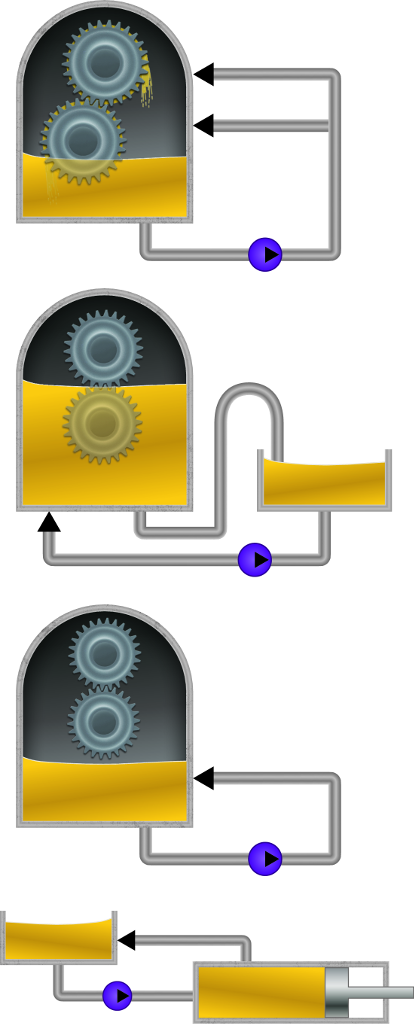

Circulating oil systems are common for large, complex equipment, but they can be adapted to work on most oil-flled housings. Machines operating with circulating oil tend to run cooler. Te lubricant also tends to last longer in these systems.

Circulating oil systems typically have a larger volume of oil, and the additional piping and pumps allow you to better condition the oil with filters and heat exchangers built into the oil loop. Of course, there is added cost for these systems, and they must be monitored for leaks and to ensure the pump is working properly.

If feasible, it would be best to go with a circulating system, as its benefits far outweigh the negatives. While this will cost more, you can better lubricate your machine if the circulating system is installed correctly. To help prolong the life of the machine and potentially the lubricant, be sure to include filtration in this type of system. Over time, this may pay for the upgrade of the system.

“What could cause a substantial reduction in the specific lubricating oil consumption (SLOC) value for a gas engine?”

There are some instances in which we have seen a sharp decline in the daily top-up of lube oil. What are the probable causes? Is crankcase ventilation pressure the culprit?”

There are some instances in which we have seen a sharp decline in the daily top-up of lube oil. What are the probable causes? Is crankcase ventilation pressure the culprit?”

To understand the reduction in oil consumption, you must first determine where the oil is going. This will help diagnose the reason for the measured decline. Some degree of oil consumption is to be expected in all engines. What is considered normal or acceptable will vary based on the application and the design of the engine.

Some engines consume oil by design from the very first time they are started. Te consumption may be as much as one quart per 1,000 miles and yet still be considered acceptable.

Speed and load also affect oil consumption. The higher the revolutions per minute, the more oil will be consumed. Te added pressure on the seals and gaskets allows some of the oil to find its way around and get burned away in the combustion chamber. In addition, the condition of the seals and gaskets should be considered. The older and more worn the seals are, the more oil will be consumed.

High operating temperatures can also impact oil consumption. Te hotter the engine runs, the lower the viscosity will be. Once again, it will be easier for a thin oil to reach the combustion chamber and get mixed and burned with the fuel. Keep in mind that there is a point at which the oil’s smaller molecules will evaporate. If the oil being used has a viscosity that is below the recommendation of the engine manufacturer, oil consumption will occur for the same reason.

High volatility is another factor in oil consumption. Usually found with lower quality base oils, the volatility is the evaporation of smaller oil molecules. This oil vapour reaches the crankcase head-space and is often pulled into the intake and consumed by the combustion process.

So, what could cause a sharp decline in oil consumption? With so many variables, it can be difficult to pinpoint a single offender. It may be just the right combination of a few factors. Te most likely causes are simple things like a viscosity change, a lubricant quality change, a seal that was once leaking but has now stopped or operational severity changes.

If you have a question for one of Noria’s experts, email it to editor@noria.com.