Accessorise your Equipment for Enhanced Reliability

When it comes to accessories, there is a common misconception among industrial fraternity that the accessories supplied by manufacturer along with the equipment are sufficient for machine inspection and its maintenance. However, it is not always true. Fact is that the most of the manufacturers usually provide only basic accessories along with the equipment to perform its intended functions. This is primarily because of its competitiveness, as every supplier wants to supply equipment as cheap as possible. They mostly focus on the basic requirement of the customer. For example, the main function of a gearbox is to achieve required torque and speed ratio. For such requirements, supplier’s main objective would be to fulfill these needs first. The gearbox might not include the required breather to avoid contamination in a dusty and humid environment, best level indicator to assist in inspection, standard oil sampling hardware to collect representative oil sample, nor proper drain arrangement required for lubrication excellence. Applying this to our real life, on purchase of an automobile in its basic form, one gets only the essential things required to drive it. For user’s superior experience and better convenience, one needs to additionally buy accessories. One can buy better Seat Cover, advanced navigation system, Dash Camera, Fog Light, Luggage Holder, etc, as the case may be. In a similar way, for predictive maintenance, better inspection, improved reliability and best lubrication practices, there is always a need to replace or modify those basic accessories supplied along with the equipment. This article is intended to provide a walkthrough of the common, useful and low cost accessories available in the market and its features that can help in enhancing the reliability of critical equipments. The accessories can help in prolonging asset life, preventing breakdown and thereby reducing maintenance cost.

Grease Nipple Cap

Grease Nipple Cap

Grease Nipple Cap is a low-cost effective solution to protect grease nipples from external contamination. It helps in guarding the grease nipple against dirt and moisture. These are available in variety of colors thus it can also help in identifying the grease to be applied on the machine, through color codification system. It thereby avoids the cross contamination of the lubricant. It can also provide an option for frequency indication. Re-greasing frequency can be indicated on the top of these caps by using different symbols. Plastic material also reduces any chance of corrosion over a period of time. Ease of availability, extreme low cost and ease of installation makes it a perfect piece of accessory that can be fitted to any manually greased application.

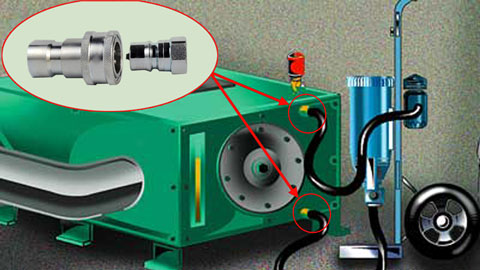

Quick Connect

Quick Connect

Quick connect provides secure and quick connection of hoses to machines that can be conveniently attached or detached. It provides speed and convenience to repeatedly connect and disconnect fluid lines. It enables ease of oil filtration, ease of oil transfer and ease of drain through portable filter cart. It has affordable price. In many equipments, there may already be a provision to install the quick connect, the equipment just needs slight modification to fit it. Also, by sizing the quick connects corresponding to different lubricant types, chances of cross contamination (due to wrong filter cart use) can be avoided.

Bottom Sediment and Water (BS&W) Bowl

Bottom Sediment and Water (BS&W) Bowl

Bottom Sediment and Water (BS&W) Bowl is made of very tough and durable change in oil color and can indicate corrosion of internal parts. Moreover, it does not cause downtime and work disruption for its inspection.

Magnetic Plug

Magnetic Plug

Magnetic plug is similar to straight thread drain plug but it has permanent magnet fastened to the plug body. While machine is in operation this magnet attracts and holds abrasive ferrous metal particles preventing their circulation through the lubrication system. These abrasive, ferrous metal particles are generated in lubricating system primarily as a result of wear and tear. Magnetic plug also facilitates in capturing vital information about the major wear occurring in machine without actually opening the machine and helps in detecting abnormal wear of machine components.

Standard Breather

Standard Breather

Breather ensures only clean and dry air enters inside the reservoir during breathing. During breathing process, depending on the operating environment, fine atmospheric debris and moisture along with the air can get inside the system. If this contaminated air is allowed to enter inside the system, it can lead to degradation of lubricant and machine components.

Breather can be classified into two major categories: spin on type filter breather and desiccant media breather. Spin on filter breather has filter media that can filter the solid contaminants coming along with the air. Whereas, desiccant breather has silica gel media along with the filter. Silica gel media allows the breather to absorb the moisture from incoming air.

While selecting a breather it is very important to consider, cleanliness and dryness requirements of the system. One type of breather does not fit all the applications. It is also important to have proper ‘close circuiting’ of the reservoir, by avoiding any open vent, to ensure breather’s effectiveness. Also, in order to indicate service requirement, it should be equipped with vacuum service indicator. Color changing type silica gel media should be preferred to indicate its saturation point.

Oil Sampling Hardware

Oil Sampling Hardware

Getting representative oil sample is a primary factor in achieving consistency and accuracy of oil analysis result. One of the steps to achieve this is to install a right sampling valve at the right location. As discussed earlier, most of the machines (except a few modern hydraulic machine supplied by major Original Equipment Manufacturers (OEMs)) are not equipped with any kind of sampling valve. If user wants to get the representative oil sample, they must modify their machine to install sampling hardware. In certain complex machines, one may also require to install secondary sampling valve(s).

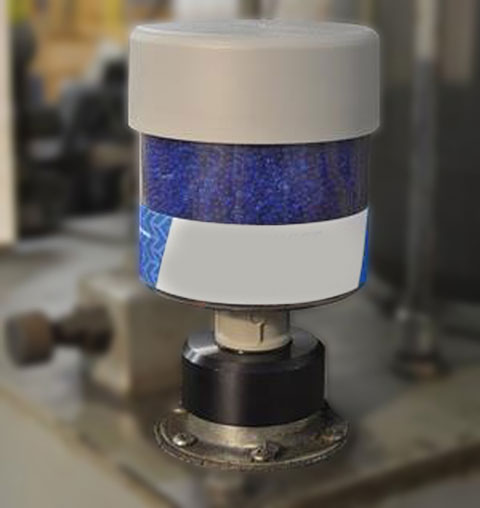

Condition Monitoring Pod (CMP)

Condition Monitoring Pod (CMP)

Condition Monitoring Pod is early fault detection, multi-parameter machine inspection tool that consists of a combination of 3-D sight glass, corrosion indicator, magnetic plug, as well as, oil sampling valve. This all in one pod lets inspection technician quickly observe oil level, color and clarity, oil aeration and foaming, corrosion, varnish and wear debris.

With one time modification, it can provide long term benefits. It facilitates oil sampling, magnetic plug inspection, serves as an oil level gauge to check oil level, detects foaming, detects signs of corrosion and indicates oil color change. One can quickly identify root causes and symptoms of failure that would have previously gone undetected.