Total Lubrication Management (TLM): A new viewpoint

Usual Approach

Usual Approach

The lubrication responsibilities at plant were assigned to unskilled and untrained workforce or to machine operator. Anyone who needed oil or grease could order any type or amount of lubricant to complete the task at hand. The result is an excessive amount of oil and grease stashed in every corner of the plant. A few people want to change their lubrication practices but they are not able to implement it on the ground level. Tese people need to understand that they will need dedicated & trained team to develop and run the lubrication program. Tis will involve understanding issues and needs of the plant’s lubrication. Starting from Inventory to disposal of discarded lubricants, the reason for lubrication failure was found to be poor quality control and poor lubrication practices resulting in increased lubricant consumption, followed by unexpected equipment downstream issues.

A number of common incorrect lubrication practices (described below) are responsible for this condition.

- Use of open contaminated galvanized top up container

- Use of single container for multiple oil grades

- Use of single barrel hand pump for multiple oil grades

- Lack of written procedures for lubrication task

- Improper handling and storage

| Under-lubrication | Over-greasing |

| Poor labelling system | Cross-contamination |

| Time/production based oil change | Lack of onsite condition monitoring |

| Unscheduled oil fltration | Flushing & cleaning of tanks |

The equipment for contamination control (flter carts/breather) is in poor condition and has not been checked and changed since equipment’s installation. As we all know that an effective lubrication program with oil analysis can provide longer equipment life, detect early signs of contamination and degradation, reduce equipment downtime and ultimately save money. In the POLARIS Laboratories OUTLOOK 2015 Benchmark Study for the Oil Analysis Industry, the following facts were determined by companies utilizing oil analysis in their preventive maintenance program:

- 80% maximized equipment uptime by using oil analysis.

- 69% optimized oil drain intervals up to twice that of standard drain intervals.

Beside the above fact, it has been observed that most plants do not have a lubrication program with oil analysis. Some of the plants have an onsite testing as well as third party testing facility but they are not aware of the importance of proper sampling procedure and lack of oil analysis report interpretation skills. The oil analysis reports are only used for audit purpose. In my opinion, it is just because of a limited knowledge on the subject and no standard training program & certifcation course available.

Modern Approach

The plants with Best in Class levels focus at great length on the management of their lubrication activities as they understand the importance of lubrication on equipment life. Lubrication practices within a plant have a direct effect on plant and equipment reliability. When a lubricant is working effectively in a machine with no chemical degradation and with limited contamination within it, wear will be reduced and equipment reliability will improve.

Lubrication management is not only topping up the oils into machine. Tis concept takes holistic approach for lubrication from cradle to grave. It starts the day the lubricant arrive onsite, and ends the day the oil is drained from the machine and disposed of safely. The industries are now focusing on the management of their lubrication activities which includes lube survey, proper storage and handling, schedule equipment inspection, oil topping up & re-greasing, onsite condition monitoring, online or ofine fltration, condition based oil change and Data analysis & interpretation. In the past few years, there has been a growing trend in establishing lubrication management services, and these organizations have been reaping handsome rewards.

Implementations

Implementations

The following new implementation at plant is being done:

- Introduce a cross check of quality of lubricants received

- Focus on contaminant exclusion at every stages

- Introduce Specialized cleaning machine

- Best sampling practices

- Interpretation of Oil analysis

- Condition based oil change

- Proper segregation of waste oils

- Lubrication Training Program

Industries focus on contaminant exclusion at every state from reception to during usage as well as they have specialized fltration machine to exclude the contaminant and maintain the required cleanliness level in the machines. Tis helps to increase drain interval, improve system performance and lower downtime & maintenance cost. They also have the standard procedure of lubrication activities like tank cleaning, sampling, oil drain, disposal etc.

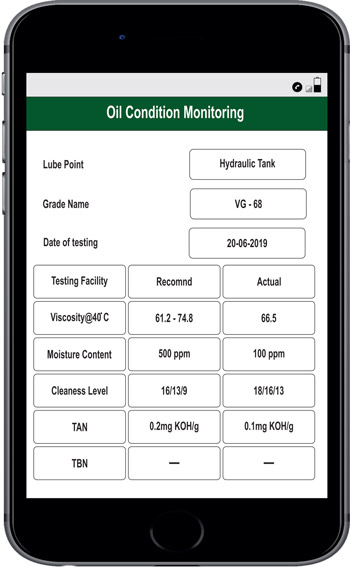

The importance of oil analysis & its interpretation has been stated. Set up an onsite laboratory at plant to get the immediate result of oil condition to take necessary action during the preventive maintenance.

Benefits

Benefits

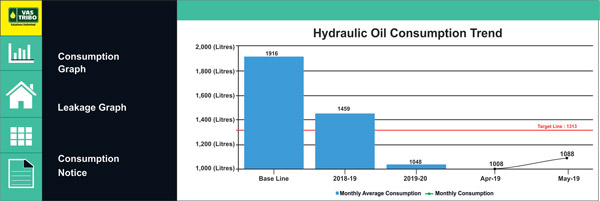

The lubrication team focused on each and every key area of lubrication and transformed the old practices into world class. Tey have overcome many lubrication challenges with a reliability focused approach and achieved 20% to 40% reduction in lubricant consumption and other improvements like reduction in spare cost, tool cost, reduction of machine downtime and improved machine availability for production service.

IT Tools (Lubrication Management Software)

Previously, the data collection, recording, segregation and reporting was done manually which could result in an error. By the introduction of mobile and web based lubrication management software, which is a great tool to collect data, manage the schedule and see the various types of trend analysis at your fngertip. The software can deliver various information such as –

- Machine criticality

- Number of lubrication points

- Lubricant being used

- Consumption trend

- Abnormality alert, Leakage Alert & stock out situation messages

- Live consumption & leakage status on display

- Schedule alarm and automatic daily report

Operational process of the software is very simple. Once you perform the lube task you need to scan the QR Code that is pasted on each machine (each lube point) with the help of mobile based application and fll & submit the task performed details. Customer having secure login ID and password can access both the application to see their lubrication activities, machine information and lubrication history of specifc machine etc.

About the author

Praveen Kumar is Head of Operations at TFM (Total Fluid Management) Services vertical of VAS Tribology Solutions, India. He has over 7 years of practical experience in the feld of TFM. He is certifed Level I Machine Lube Tech through International Council for Machinery Lubrication (ICML). Contact: praveenkumar@tribologysolutions.com