Advertorial: Particle Contamination & Measurement

Particle contamination can be described as any dirt (silica), metal, soot or soft insoluble material that is not designed to be present, but which gains access to the lubrication system. It has the potential to damage the lubricant and the component’s lubricating surfaces.

Particle contamination can be described as any dirt (silica), metal, soot or soft insoluble material that is not designed to be present, but which gains access to the lubrication system. It has the potential to damage the lubricant and the component’s lubricating surfaces.

There are several ways, where the contamination gets entry in to the lubrication system, mainly transportation, storage, handling and machine itself. Particles begin to cause different types of wear and drastically affect the additive depletion rate. Wear can occur on the lubricating surface through mechanical wear, chemical wear or surface fatigue.

Mechanical wear happens through a variety of different mechanisms. Adhesive mechanical wear, also known as galling, scuffing or seizing, Abrasion, erosion, chemical wear, surface fatigue etc. takes place in different types of applications like heavily loaded, sliding- contact, rolling element bearing, gears, hydraulic systems, cylinders etc.

Mechanical wear happens through a variety of different mechanisms. Adhesive mechanical wear, also known as galling, scuffing or seizing, Abrasion, erosion, chemical wear, surface fatigue etc. takes place in different types of applications like heavily loaded, sliding- contact, rolling element bearing, gears, hydraulic systems, cylinders etc.

Contamination is the cause of approximately 90% of all hydraulic system failures. If the systems are maintained at the desired cleanliness level, which will provide you high efficiency, longer equipment life, more runtime.

How to Plan an Action?

Data availability & trending is the base of every action plan. If we have a reliable meaningful data, then only we can take an action & get the desired results. Data will give us direction, what & where we need to take the action. Action without data is meaningless & waste of resources.

Reliable/Meaningful Data?

There are many different type of analysis instruments available in the market to check the particle contamination, but are they really giving you a meaningful or correct data? Many industries using cheap LED particle monitors, because their customers/authorities have asked them to have particle counters. These monitors are not fulfilling any requirements of ISO1171 & ISO4402, which is primary requirement of measurement. They are not calibrated & data authenticity is zero. To find out the particle contamination level, we need an instrument of high accuracy, high reliability, repeatability & traceability.

There are many different type of analysis instruments available in the market to check the particle contamination, but are they really giving you a meaningful or correct data? Many industries using cheap LED particle monitors, because their customers/authorities have asked them to have particle counters. These monitors are not fulfilling any requirements of ISO1171 & ISO4402, which is primary requirement of measurement. They are not calibrated & data authenticity is zero. To find out the particle contamination level, we need an instrument of high accuracy, high reliability, repeatability & traceability.

Why PAMAS?

Why PAMAS?

Only a reliable instrument can provide you reliable data with accuracy. PAMAS GmbH particle counters are well-known for its quality & performance. A volumetric sensor design gives you the power to analyze 100% of the sample taken by instrument. Sensor which can handle particle concentration of 24000/ ml & a viscosity range up to 1000cst @40 degree Celsius Two independent separate Calibrations as per ISO 4402 & ISO11171 standards. Only a meaningful data can lead you towards a successful & effective lubricating management system. Data authenticity is the base for planned action.

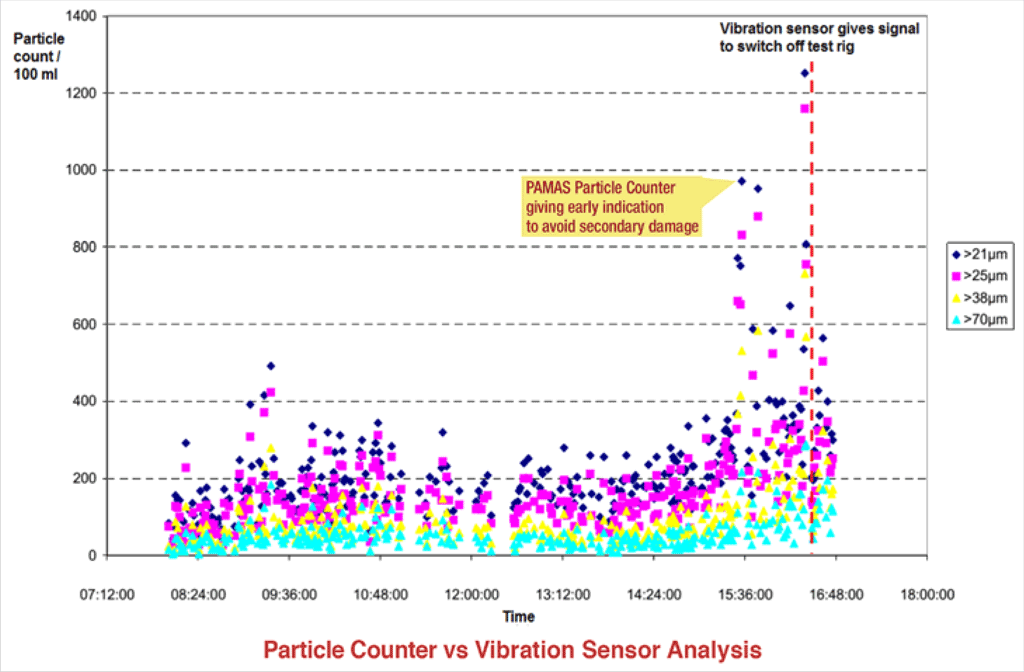

Avoid secondary damage by using PAMAS reliable particle counter, which will give you early indication of problem by providing you correct data for your lubrication condition.

Benefits of the only particle counter system with both ISO4402 (ACFTD) & ISO11171 (ISO MTD) calibration.

- Reduce Breakdown

- Reduce Maintenance Cost

- Reduce Oil Consumption

- Increase Machine Life

- Increase Efficiency

Pioneer in the field of liquid application, produces the particle counter for every liquid applications like Oils, Lubricants, Fuels, Water, Water Glycol, Hydraulic Oils, Pharmaceutical, Chemicals and many more.

We have solutions for every liquid application

Book your free Demo now.

Contact: +91 9992843648 / +91 8041150039

Email: harveer.singh@pamas.in / info@pamas.in