Selecting Lubricants Based on Specifications

Effective lubricant selection must strike a balance between quality, application and affordability. In order to achieve and maintain this balance, lubricant specifications should be created to serve as a guideline for what to purchase and how to use it. This article will discuss the necessary steps for creating lubricant specifications and how they can lead to sustained machine reliability.

What Are Lubricant Specifications?

Lubricant specifications are internal documents that contain the technical standards, performance requirements and industry approvals for every lubricant used in the facility or fleet. They may include information on product safety, proper disposal or alternative products available on the market. Among the lubricants typically found in these specifications are gear oils, turbine oils, hydraulic fluids, compressor oils, greases, solid lubricants, multi-purpose bearing oils, engine oils, cutting fluids, total-loss lubricants and others.

For small facilities or fleets, creating lubricant specifications can be a relatively simple exercise. However, the complexity often increases according to the facility’s equipment diversity or the number of sites involved. The more complex the facilities or the higher the number of sites involved, the greater the value of creating specifications.

Elements of Lubricant Specifications

Depending on the needs of the plant or fleet, lubricant specifications may consist of the following elements:

Scope of Application

This defines the lubricant’s general function or purpose as well as the material type. It also describes specific applications within the facility. For example, the lubricant defined by this specification is an API Group II mineral gear oil containing extreme-pressure additives. It is intended for use in gearboxes operating at temperatures up to 160 degrees F and which are lubricated by bath or circulation systems.

Physical and Chemical Properties

These are the intrinsic physical and chemical properties of the lubricant. Here it is important to identify not only the testing parameters used but also the expected test results. An ASTM or appropriate test method should also be referenced. Examples include ISO viscosity grades (ASTM D2422), minimum viscosity index (ASTM D2270), aniline point (ASTM D611), flash point (ASTM D92) and thickener type.

Performance Properties

These refer to bench and laboratory tests that the lubricant formula should pass at a minimum level. Examples include copper corrosion protection (ASTM D130), demulsibility (ASTM D1401) and dropping point (ASTM D2265).

Product Compatibility

Product Compatibility

This describes the concerns or characteristics of the product’s compatibility with other lubricants as well as with synthetic materials existing in machine lubrication systems, such as seals and gaskets. This section may have added importance when the standard refers to synthetic lubricants or special formulas, since they may require specific procedures when switching to other lubricants. For example, this product is manufactured with polyalkylene glycol (polyglycol) base stock, which is not compatible with mineral oils and other synthetics such as polyalphaolephins.

Product Approvals

These are the lubricant approvals or endorsements required by the specific machine(s) in which the product is intended to be used. They may come from original equipment manufacturers (OEMs) or other industry organizations, such as the American Gear Manufacturers Association (AGMA), the National Lubricating Grease Institute (NLGI), etc. Please note that some lubricants may claim a certification or approval for certain technical standards or OEM specifications, while others may only “comply with” the standard or requirement but are not necessarily approved or certified. This may be particularly significant when complying with equipment warranty requirements.

Potential Restrictions and Hazards

This section describes any undesired ingredients or product properties as well as toxicological or safety aspects to be considered when buying or handling the lubricant. For example, the product must not have mutagenic or carcinogenic compounds.

Lubricant Identification System

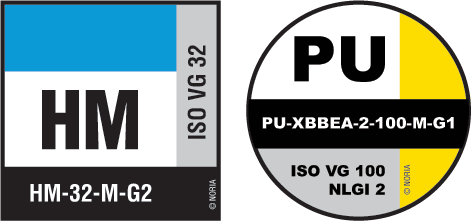

Lubricant Identification System

Every lubricant to be used in the plant should have a unique identification code to prevent mislabeling or misapplication. The classification should be independent of the brand name. In a proper identification system, every product will have unique visual and written codes. For example, a hydraulic oil may have a square lube identification tag, while a grease may have a round tag.

Quality Control at Reception

This element specifies the tests to be conducted on lubricants entering the facility in order to verify product quality. Here it is necessary to define laboratory or field tests as well as the acceptable results or limits. ASTM methods, test equipment, field test kits and product inspections may be referenced. See the example below.

Supplier Requirements

This section identifies the requirements for the lubricant supplier relating to product quality. For example, the supplier should be ISO 9000-certified, or every batch of lubricant should be sent with a certificate of analysis. The lubricant supplier approval process can provide more detailed information about the supplier.

Lubricant Disposal

This element provides general or specific requirements for lubricant disposal based on the product type, formula, contaminants and lubricant volumes. These requirements should be defined according to local regulations and corporate policies.

Supporting Information

This information supplements the specifications’ technical descriptions. It may include a glossary of terms, ISO viscosity grades, NLGI classifications and ASTM standards.

| Test or Property | Base | Min. | Max. |

|---|---|---|---|

| Viscosity at 20°C (cSt) |

Field viscometer |

170 | 200 |

| Acid number (mg KOH/g of oil) |

Field test kit | 1.1 | 1.4 |

| Particle count | Particle counter / ISO 4406:99 |

- - - | 19/16/13 |

| Moisture analysis (ppm) |

Calcium hydride kit |

- - - | 500 |

Creating Lubricant Specifications

The process of creating lubricant specifications should first begin by developing or updating the database of machines, lubrication points and lubricants in the plant or fleet. Product recommendations will come primarily from OEMs, lubricant suppliers, consulting companies or internal experience. Other technical references may also be consulted, such as the AGMA, ISO, NLGI and others. For critical machines, additional validation may be needed to ensure the selected lubricant fulfills the lubrication requirements based on the equipment’s current operating conditions.

Once the database of lubricants and lubrication points has been completed, it is time to consider product consolidation. The goal is to minimize the number of lubricants used in the plant while still maintaining appropriate lubrication of all machines. The consolidation process should help identify products that are equivalent, lubricants that have similar specifications, machines that can utilize multi-purpose lubricants and when it is practical to use a higher quality lubricant.

At this point, a consolidated list of lubricants can be generated, including all equipment applications for each product. The next step is to create specifications for every lubricant or lubricant family. Whenever possible, the information should be categorized by product family, i.e., all lubricants that have similar properties but differ only by viscosity grade. If there is a single lubricant with special properties for a specific application, a lubricant specification document should be produced just for it.

Creating these specifications may involve several different departments such as engineering, maintenance and purchasing. Lubrication knowledge will be required as well as access to equipment manuals and lubricant requirements. Expert outsourcing support can be employed when internal resources are limited.

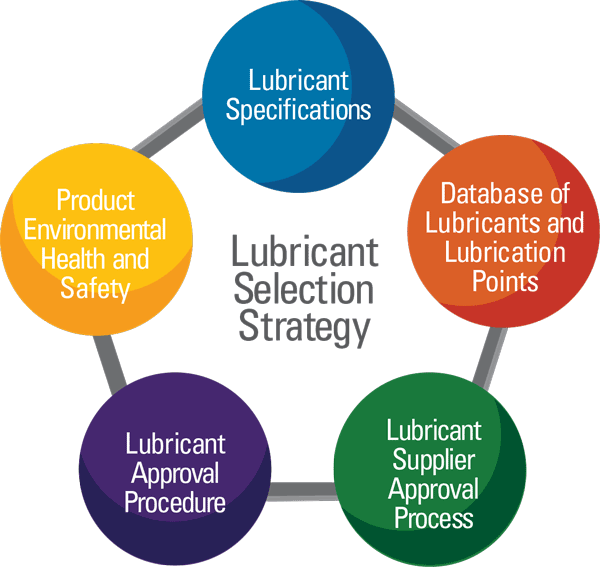

Keep in mind that the specifications as well as the database of lubricants and lubrication points must be updated whenever there is an equipment change or new product option. An overall review of the system should also be conducted on a yearly basis. This system may be part of an overall lubricant selection initiative as illustrated above.

In conclusion, lubricant specifications are effective guidelines for selecting and using the right lubricants in the right applications. These documents not only can help ensure quality products are acquired at the best possible price, but they can also provide guidance to lubricant suppliers, simplify lubricant handling and application, improve lubricant management, and reduce costs at different levels of your organization.

Noria Corporation helps companies optimize lubrication programs. Learn more.