Real-Time Oil Monitoring: The smarter way to clean your oil

During the two decades that we have been serving the Marine Industry, we have observed that Engineers, in general, do not pay enough attention to oil cleanliness. Oil samples, for Lab analysis, are drawn without much care and attention to detail, samples stay on board for days or weeks before they are landed ashore and once the samples are analysed by the laboratory, it might be weeks before the report reaches the vessel. The story does not end there. The apathy to oil continues. The Chief Engineer at best may spend a couple of minutes before his eyes rest on the ‘fit / unfit for further use’ advice and then files the report. Rarely do the other engineers ever study it or treat it as a diagnostic tool. Oil sample analysis should be a valuable tool for the ship’s engineer to take proactive steps in preventing failures. Getting a report a month after the sample is drawn is akin to telling a dead patient that he had a bad heart!

It is our experience, and this is backed by field tests and independent research data, that keeping your oil super clean ensures a 30-40% savings in Opex cost (oil changes, oil filters and savings in the cost of overhauls). The reliability of the equipment is significantly enhanced.

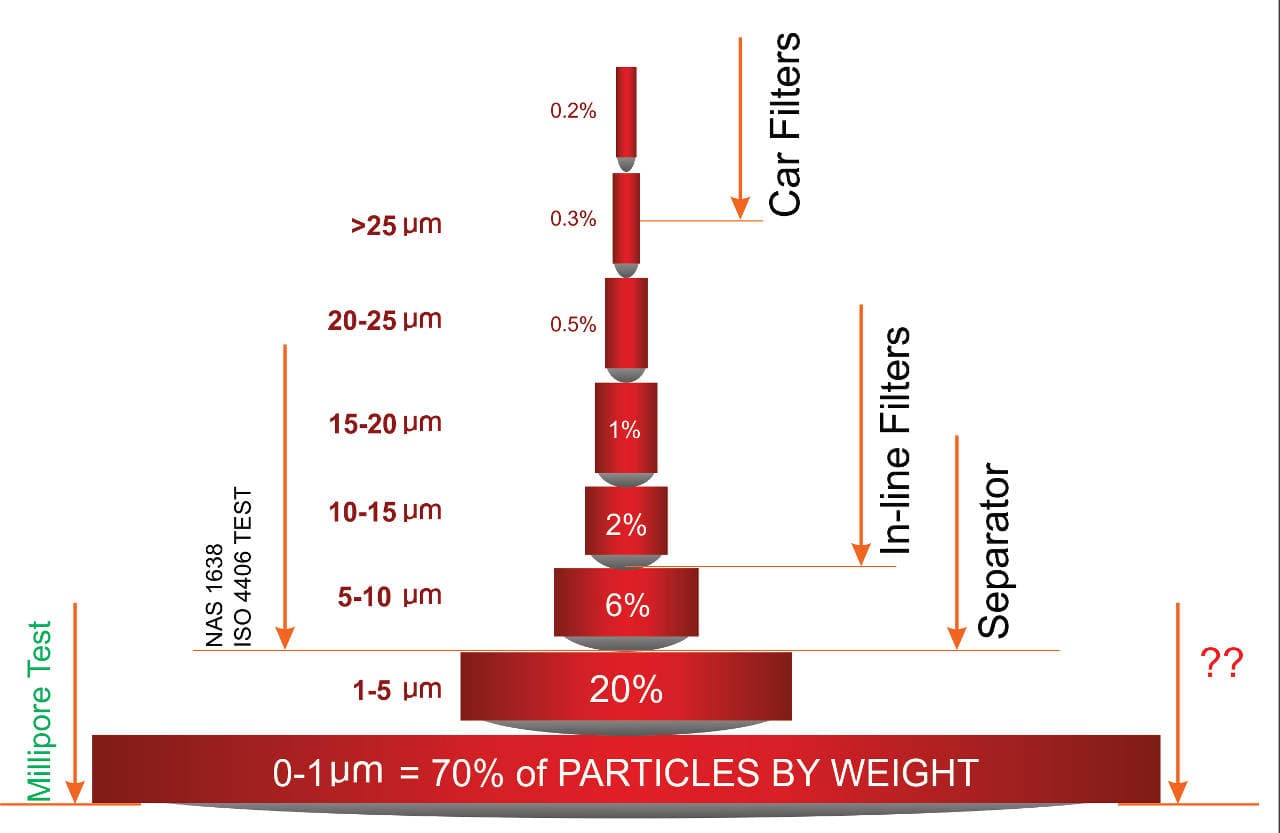

99% of wear and contaminant particles in oil are below 5micron in size. Online filters in Diesel engines (and most equipment) are about 8-10 microns. Return line filters on hydraulic systems are typically 8 microns. These filters are adequate in protecting moving parts from the ingress of wear particles between rubbing surfaces to prevent abrasion damage. That is their primary purpose. The millions of particles which are 5 micron and less in size are the cause of concern. In the presence of heat, oxygen, and pressure they act as a catalyst and promote rapid oxidation of the oil. The products of oil oxidation are acids, sludge, and varnish. The brown grime you see at the bottom of a hydraulic oil tank is varnish. It reduces the load-bearing capacity of the oil film, promotes accelerated wear, which in turn produces more wear particles and the cycle continues. Varnish, in turn, causes hydraulic control valves (spools, flow control, proportionate control valves etc.) to stick and leads to malfunction of hydraulic systems.

99% of wear and contaminant particles in oil are below 5micron in size. Online filters in Diesel engines (and most equipment) are about 8-10 microns. Return line filters on hydraulic systems are typically 8 microns. These filters are adequate in protecting moving parts from the ingress of wear particles between rubbing surfaces to prevent abrasion damage. That is their primary purpose. The millions of particles which are 5 micron and less in size are the cause of concern. In the presence of heat, oxygen, and pressure they act as a catalyst and promote rapid oxidation of the oil. The products of oil oxidation are acids, sludge, and varnish. The brown grime you see at the bottom of a hydraulic oil tank is varnish. It reduces the load-bearing capacity of the oil film, promotes accelerated wear, which in turn produces more wear particles and the cycle continues. Varnish, in turn, causes hydraulic control valves (spools, flow control, proportionate control valves etc.) to stick and leads to malfunction of hydraulic systems.

The Solution: Bypass Kidney Loop Filtering Systems

The solution is ‘offline’ or ‘kidney loop filtering systems’. The flow rate generally is calculated to give one pass of the sump volume in about 24 hours. Typically for a sump of 2000 litres, the flow rate in the bypass filter should be 1.5 LPM with a suitable filter size. The flow rate may vary depending upon the ingress of contaminants in the system. There are two types of offline systems – those systems which draw the oil from the main lubricating system and pass it through the offline filters before returning it to the sump, the other being completely independent systems having their own motor-driven pumps. The latter are costlier but are easier to install. Personally I prefer independent systems (with integrated pump and motor) over those that draw oil from the main lubricating oil system. My main concern is that when the equipment is starting or stopping (Diesel engines) lubrication conditions are most severe (maximum wear occurs in moving parts until hydrodynamic lubrication conditions are established), and diverting any amount of oil to the offline filters can only adversely affect the quality of lubrication in the main bearings. The other disadvantage is that when the equipment is stopped the offline filtration is also stopped. In systems with independent pump and motor, purification of oil is a 24X7 process.

The solution is ‘offline’ or ‘kidney loop filtering systems’. The flow rate generally is calculated to give one pass of the sump volume in about 24 hours. Typically for a sump of 2000 litres, the flow rate in the bypass filter should be 1.5 LPM with a suitable filter size. The flow rate may vary depending upon the ingress of contaminants in the system. There are two types of offline systems – those systems which draw the oil from the main lubricating system and pass it through the offline filters before returning it to the sump, the other being completely independent systems having their own motor-driven pumps. The latter are costlier but are easier to install. Personally I prefer independent systems (with integrated pump and motor) over those that draw oil from the main lubricating oil system. My main concern is that when the equipment is starting or stopping (Diesel engines) lubrication conditions are most severe (maximum wear occurs in moving parts until hydrodynamic lubrication conditions are established), and diverting any amount of oil to the offline filters can only adversely affect the quality of lubrication in the main bearings. The other disadvantage is that when the equipment is stopped the offline filtration is also stopped. In systems with independent pump and motor, purification of oil is a 24X7 process.

Filter Rating: The Importance of the Beta Ratio

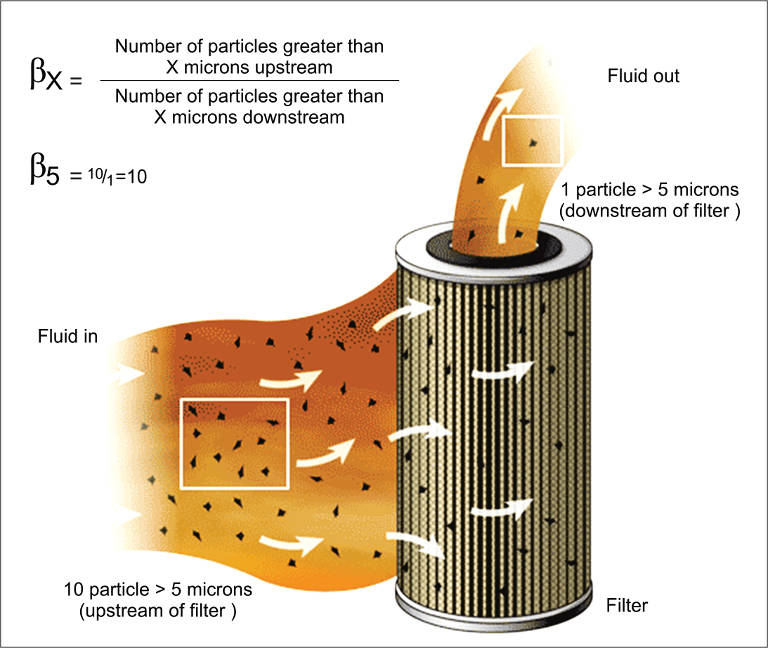

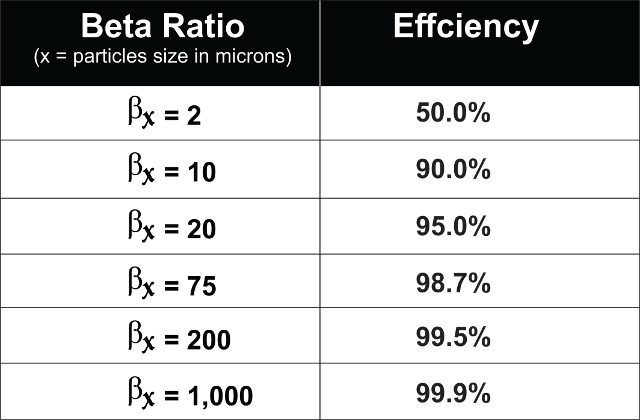

Filter manufacturers use ‘Nominal rating’ to describe the filter efficiency. Most online filters have a nominal rating of 8 or 10 microns. This may mean ‘most’ particles of 8 microns can be trapped by the filter. In reality, both Nominal rating and Absolute rating are meaningless terms. They can be quite misleading. A 10 micron ‘nominal rating’ filter may allow particles several microns larger to pass through it. Probably the best indicator of filter efficiency is the beta ratio.

Filter manufacturers use ‘Nominal rating’ to describe the filter efficiency. Most online filters have a nominal rating of 8 or 10 microns. This may mean ‘most’ particles of 8 microns can be trapped by the filter. In reality, both Nominal rating and Absolute rating are meaningless terms. They can be quite misleading. A 10 micron ‘nominal rating’ filter may allow particles several microns larger to pass through it. Probably the best indicator of filter efficiency is the beta ratio.

For example, β3= 230 implies that for every 230 particles of 3 micron or more particle may pass through the filter. A β3=500 is obviously a better filter as only 1 out 500 particles, 3 microns or more will pass through the filter. The dirt-holding capacity of the filter defines, in grams, the number of contaminants it can hold before it is clogged. Filters made from cellulose material can also hold some amount of water. This is particularly useful in trapping water in hydraulic or Diesel engine applications.

Oil Analysis

The results of an oil analysis can be accurate (and therefore useful as a maintenance tool) if the oil sample is consistent. That means it must always be drawn from the same sampling point, preferably where there is a flow of oil. The sampling bottle must be clean (and sealed) prior to use. Drain a few hundred ml of oil before filling the sampling bottle. Unless the label is accurately filled with information, the data is useless. The minimum information required is the identification of the machine, the grade of oil, machine running hours, hours since change. Most engineers do not bother to record the quantity of top-up oil used. This vital information is vital to assess the rate at which oil is deteriorating.

Particle Count

One of the ways of determining the quality of the oil is by understanding the contamination by measuring the sizes of the particles in the respective size brackets as defined by international standards like ISO 4406 or NAS 1638. The NAS 1638 standard gives the engineer an easy way to determine the particle contamination of the oil by the use of a single integer from 0-12. ISO 4406 is considered to be a better standard to gauge particle contamination in oil by specifically accounting for particles between 4μ-6μ, 6μ-14μ and above 14μ. It is important to understand that the NAS level or ISO 4406 standard can only give a partial understanding of the overall oil condition

Online Oil Monitoring

The results of the Oil Analysis can be useful if the report is delivered to the vessel as quickly after the sample is drawn. A 100 hours is the most ideal situation. However, the reality is different due to the logistics challenges that a vessel or offshore installation faces. Very often the oil report finally comes to the vessel weeks after the sample is drawn. Any useful benefit that the Ship’s engineer may have had by analysing the report, if it arrived on time is diluted. How useful is it to know that your oil is diluted with fuel oil several weeks after it has been changed?

The results of the Oil Analysis can be useful if the report is delivered to the vessel as quickly after the sample is drawn. A 100 hours is the most ideal situation. However, the reality is different due to the logistics challenges that a vessel or offshore installation faces. Very often the oil report finally comes to the vessel weeks after the sample is drawn. Any useful benefit that the Ship’s engineer may have had by analysing the report, if it arrived on time is diluted. How useful is it to know that your oil is diluted with fuel oil several weeks after it has been changed?

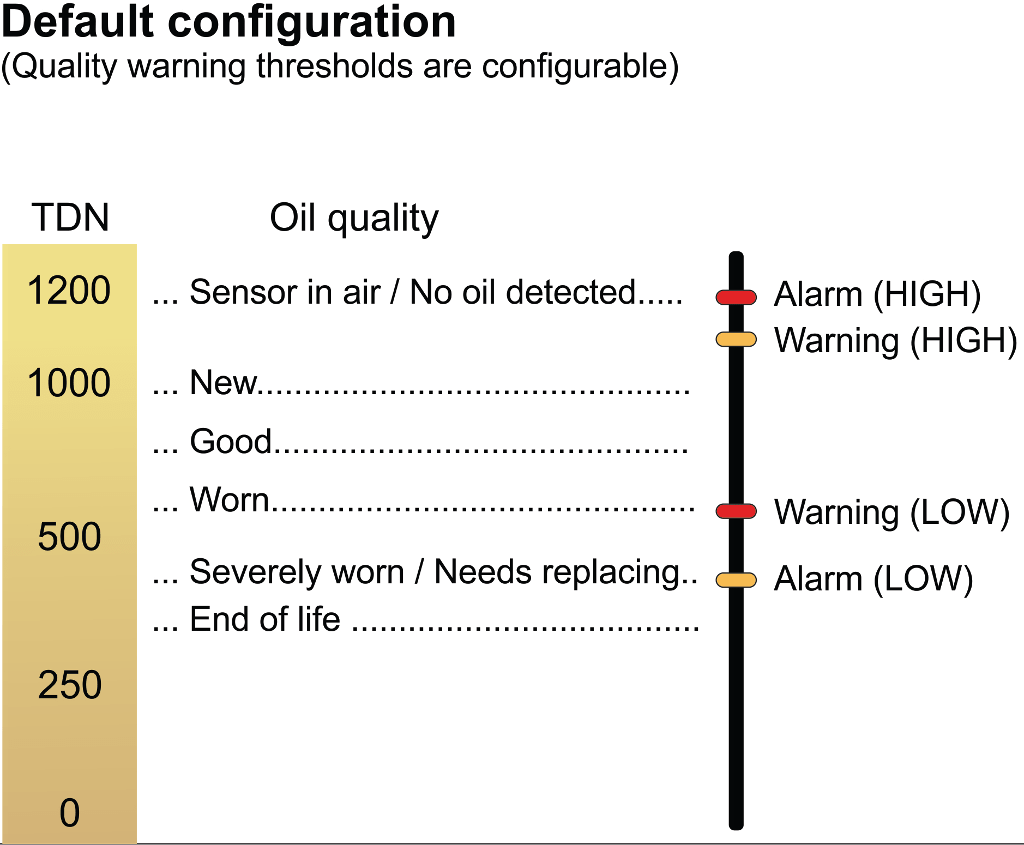

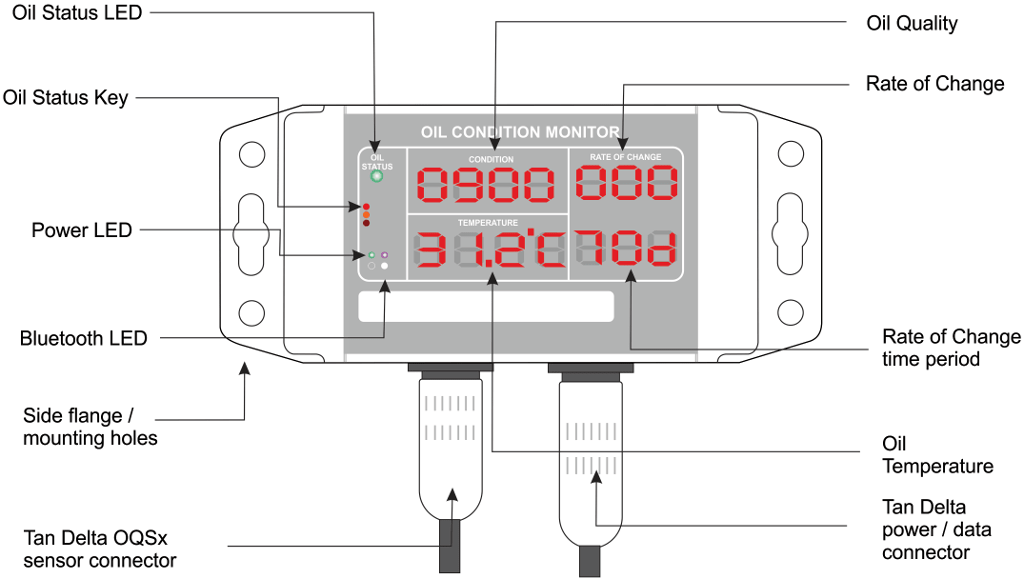

Online oil monitoring systems appear to be the answer and are now affordable. They give the user a visual indication of the quality of the oil, all in real-time. The more advanced systems now display a rate of oil deterioration and the estimated useful life of the oil. This means that if there is a sudden fuel leakage into the sump or ingress of water, an alarm can alert the Engineer and corrective action can be initiated before the oil is unfit for further use.

Another important reason to install online monitoring systems is that oil change can be extended to extract the maximum useful life of the oil. Often, especially in high-speed engines, an oil change is based on running hours of the equipment and not on the actual condition of the oil. Since the Ship’s Engineer now has real-time data of the condition of the oil he can extend oil change intervals. That saves a lot of money to the ship-owner and optimizes the usage of resources. Most of these systems can be integrated with either the ship’s control panels or can be connected to the ship’s internet for remote monitoring at the head office.

Field Tests with Offline Filter Systems

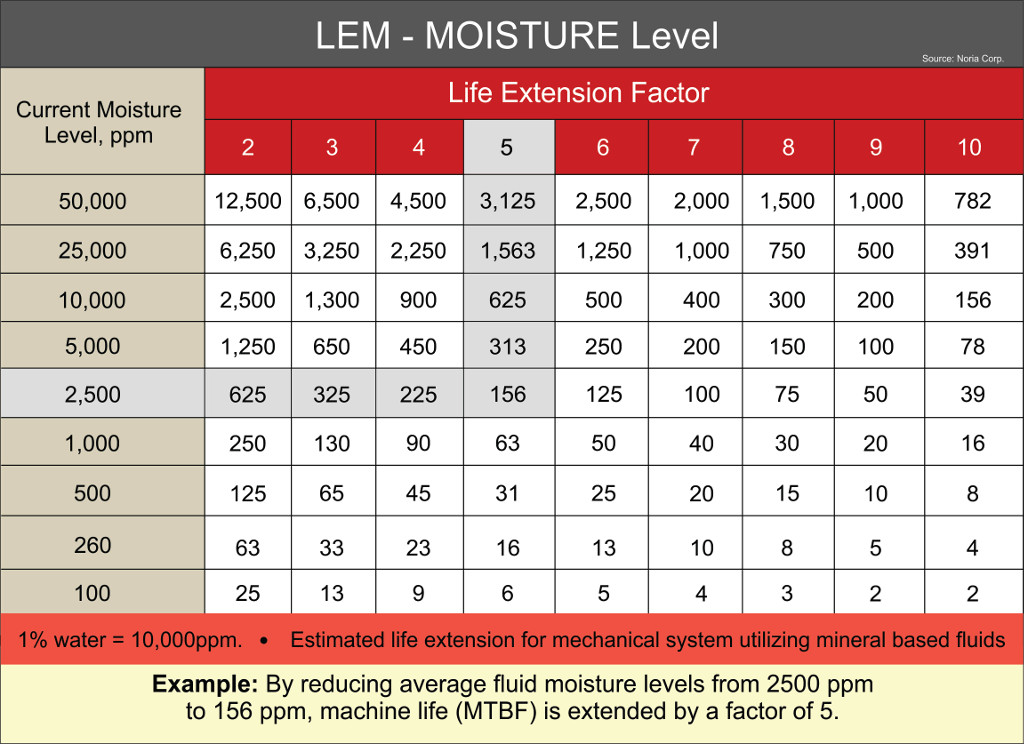

Choosing the proper bypass filtration system is important. Certain electrostatic bypass filters become ineffective in the presence of even small quantities of water in the oil. Those without inbuilt motor and pump are idle when the main equipment is not working negating the very purpose of having bypass filters. Certain other types clog easily in the presence of moisture in the oil. Our experience is that we have been able to extend the life of the oil by a factor of 5 to 10 times using a properly designed bypass filtration system. That means that the payback period of the additional filtration system is very often less than a year. But our experience indicates that the main advantage of using bypass filtration systems is the prolonged MTBO.

The clean oil ensures ideal lubrication conditions and this, in turn, increases the life of components by at least 25%.

And finally a word on Oil filling. Most of us presume that new oil is clean, that oil from a sealed drum is fit for use directly in a system. This is far from the truth. New oil has a high particle count, often it is more contaminated than the oil in your hydraulic system. Oil filling into the system must be done through an online oil filling filter no less than 5 micron in size. Ensure that you keep your system tight and leak-free, prevent the ingress of air and dirt. Bypass filtration with online oil monitoring is the best bet to keep your equipment in ship- shape and save big bucks on maintenance costs.MLI