What If You Observe Diesel Smell in Open Gear Lubricant

While passing by cement plants, you must have noticed rotary kilns. These can be clearly identified from quite far by their shape – long horizontal cylinder slightly inclined at one end. And those who have visited cement plants are aware that to enable them to rotate, they are provided with gears mounted on their outer surface, at one end. And since they are not enclosed hence the name – open gear.

While passing by cement plants, you must have noticed rotary kilns. These can be clearly identified from quite far by their shape – long horizontal cylinder slightly inclined at one end. And those who have visited cement plants are aware that to enable them to rotate, they are provided with gears mounted on their outer surface, at one end. And since they are not enclosed hence the name – open gear.

These open gears are lubricated by open gear lubricants (OGL). This is a pumpable grease. The application is usually by spray lubrication and a lot of expertise is involved in the manufacture of these OGL and fixing the quantity i.e., quantity sprayed per minute.

The incidence dates back to when I was working with one of the manufacturers of open gear lubricants. We received a complaint from one of the reputed cement manufacturers that their OGL drum was having diesel. The actual complaint was that the grease was not stable to temperature and on application was becoming thin and smelling like diesel.

Since I was directly involved with the manufacturing of the grease, I was confident that diesel could not have entered the OGL drum at manufacturing end except for deliberate sabotage. Also the formulation was time tested for such application. Over the years it was being used in cement industries around the world with no complaints of thinning. So a quick but systematic investigation was carried out at our end.

- The batch log-sheet was verified to ascertain whether specified procedure was followed and all parameters maintained as specified.

- The batch retainer sample was checked and found to be OK.

- Drums from same batch at another customer had no complaint.

Since the cement company had been a long-standing customer, we decided to visit their plant to investigate the issue.

As soon as we arrived, we were taken to their maintenance workshop. And there, we were shown one of their drums which was without lid. The customer representative had a meter long steel pipe by which he stirred the contents and showed us. It did not require any testing to see that it was a low viscosity product (but more viscous than diesel) and also smelled like diesel.

Further, he went on to show us their record sheets to convince us that the temperature of kiln had not increased beyond recommended range.

We asked them to show a sealed drum, so we were taken to their warehouse. We got the drum opened in our presence and we evidenced to the customer’s representative that the content was perfectly like usual OGL grease and not thin. We offered to take a sample and get it tested in our lab and send them the report. But he was not satisfied saying that the OGL was not of good quality and would get thin on application and hence damage the gear. [Rectification cost of a damaged girth gear runs into lakhs of rupees]. Now this was quite puzzling, there seemed to be no logical explanation for the thinning of grease and the diesel smell.

At our wit’s end, we re-sealed the drum and requested him to show us point of application i.e. the spray system on the girth gear. So, we climbed up to the top platform of the rotary kiln; inspected the girth gear and spraying system. Everything seemed to be in order. We climbed down and with sad faces asked for cotton waste to wipe our hands.

At our wit’s end, we re-sealed the drum and requested him to show us point of application i.e. the spray system on the girth gear. So, we climbed up to the top platform of the rotary kiln; inspected the girth gear and spraying system. Everything seemed to be in order. We climbed down and with sad faces asked for cotton waste to wipe our hands.

The customer’s representative directed a helper to give us cotton waste and then take us back to his office. We went into the room which houses the OGL pumping station. We took some cotton waste kept there and were wiping our hands and noticed diesel smell in the room. On enquiring, the helper showed us an open drum with diesel. Out of curiosity, we asked why diesel was kept there. And then the story unfolded.

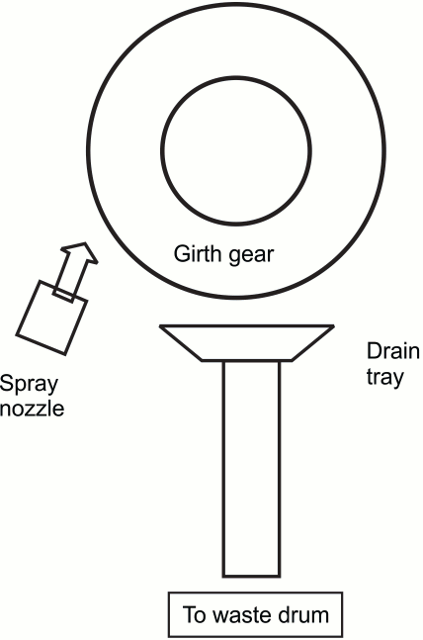

A couple of days ago, shut down for maintenance was planned for the kiln. The girth gear was completely cleaned using diesel. The arrangement at girth gear is shown in the sketch. It has spray nozzles which sprays OGL on the girth gear. Due to rotary motion, some portion of the OGL gets thrown due to centrifugal force. There was a tray below the girth gear to collect this and a wide pipe attached to allow it to drop down to a collecting drum, which was kept in the OGL pumping station room.

So, when the girth gear was cleaned, a mixture of OGL and diesel got collected in the drum. It went unnoticed and was not shifted out from there during maintenance. When the kiln was started someone noticed this drum and the thin OGL with diesel smell issue went right up to the senior plant management. And from them the complaint was passed on to us.

We concluded our visit by meeting the senior engineering manager who thanked us for the investigation.

In our report, we recommended that the waste OGL should not be collected in branded drum. This would avoid confusion and also prevent its use by someone attaching it to OGL pumping station. In fact, this is also a requirement as per ISO standards.