How Far is India’s EV Dream?

India has boldly announced its intention to move towards 100 percent electric vehicles (EVs) by 2030, following the Paris Agreement 2015. The Paris Agreement is a landmark environmental accord that was adopted by nearly every nation to address climate change and its negative impacts. As per the data, India has a long way to go. For example, the number of electric cars grew by about 300 percent in the last decade. However, the absolute number is only around 4,000 electric cars on Indian roads, which is just about 0.1 percent of around 3.5 million cars sold in 2019.

India has boldly announced its intention to move towards 100 percent electric vehicles (EVs) by 2030, following the Paris Agreement 2015. The Paris Agreement is a landmark environmental accord that was adopted by nearly every nation to address climate change and its negative impacts. As per the data, India has a long way to go. For example, the number of electric cars grew by about 300 percent in the last decade. However, the absolute number is only around 4,000 electric cars on Indian roads, which is just about 0.1 percent of around 3.5 million cars sold in 2019.

India is a market that provides an incredible opportunity in the EV space—just like it does in petrol and diesel car segments. Recently, the GST Council reduced the taxes on EVs from 12% to 5%. Similarly, Phase 2 of the Faster Adoption and Manufacturing of Hybrid and Electric vehicles (FAME) scheme is now gathering momentum. The government is looking to tighten the Corporate Average Fuel Economy (CAFE) norms, in a bid to push automakers to increase production of electric vehicles. Even at this year’s Auto Expo, electric vehicles were clearly the show- stoppers.

Though Government is doing commendable work in creating an empowering environment for EVs, most of the manufacturers are yet to establish a proper ecosystem for developing and manufacturing electric vehicles in India. Let’s put some light on the challenges EVs are facing in India.

Requirements of EV Charging Stations

To meet the charging requirement for 20 Lakh electric cars, India needs about 4 Lakh charging stations installed by 2026. Currently, India is said to have around 300 public EV chargers compared to 57,000 petrol pumps. A joint venture under the ministry of power, the government of India, Energy Efficiency Service Limited (EESL) is a public service energy and infrastructure provider that focuses on implementing energy efficiency programmes for public projects and public-private partnerships.

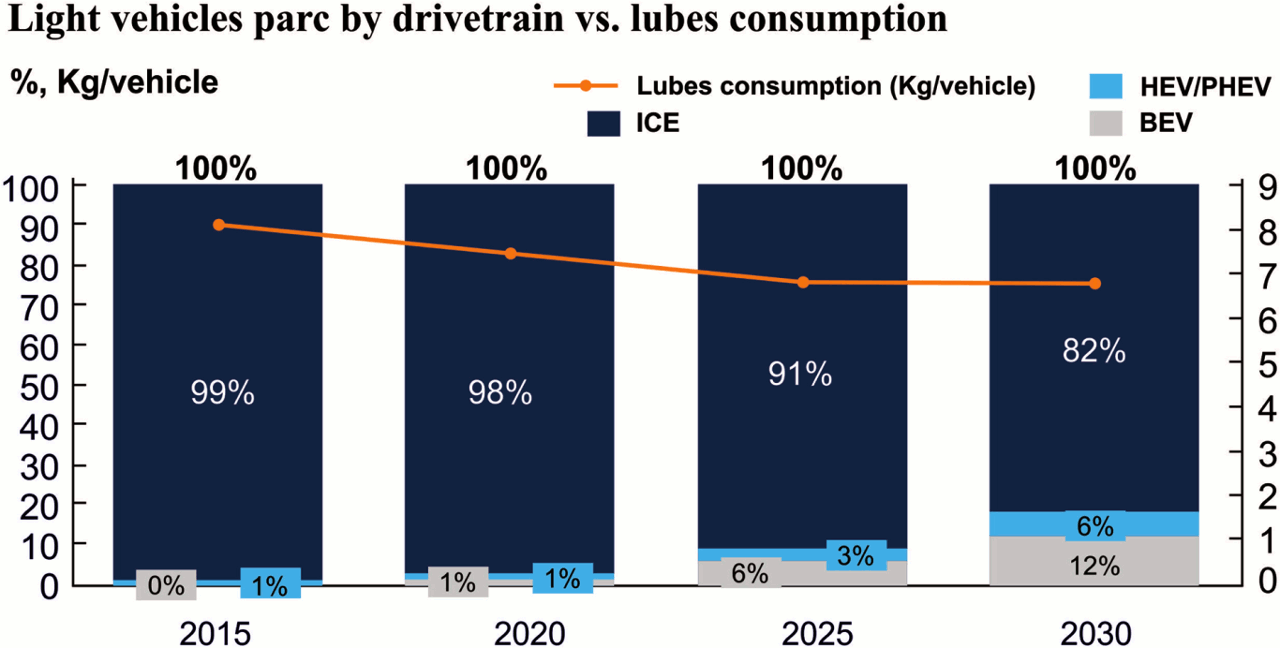

Lubrication Challenges

All the Original Equipment Manufacturer (OEM) companies are trying out different solutions. They themselves are in a learning phase when it comes to which concepts are reliable and suitable for the future. As the future demands completely electric vehicles, the development of engine oil must continue. When the development of completely electric vehicles intensifies, other product groups will also be affected. Whole new demands will be placed on gear oils, coolants and greases, partly because they will be in contact with electric modules, sensors and circuits, and will be affected by electrical current and electromagnetic fields.

Moreover, motors in electric cars also emit a lot of heat, which will need to be led away from the electric module. Here, effective cooling concepts will be increasingly important. It is also likely that the electric motors will be driven at higher speeds in order to increase efficiency. Already brand new motors are being designed, and different lubrication and cooling concepts are being discussed. With high- speed electric motors, the Revolutions per minute (RPM) in the drivetrain will need to decrease. New reduction gears with less gear steps are therefore being implemented, with potentially higher input speeds. Since the reduction gears can be combined with electric modules, their gear oils too must work well with the chosen module materials. This transition is a major challenge for developers of lubricants, since it involves a considerable change in lubricant specifications.

There are two pressing issues which India should focus on. First, get prepared for the coming disruption in the automobile industry. Fully adopted EVs will kill most of the auto component firms. Survivors will have to move to an industry 4.0 format. India would also need to reskill a large number of motor mechanics. They cannot repair EVs because of the sophisticated electronics. Second, and, more important, India should use the next ten years frame to become a leader in next-generation battery technology. This is an honourable way to pursue EV dreams without being critically dependent on any country.

Price: The Biggest Challenge For EVs

According to BloombergNEF (BNEF), electric cars won’t achieve price parity with gasoline-powered cars until the early 2030s. “Mass adoption of electric cars in India will not happen unless the gap in upfront prices of electric and ICE vehicles is brought down," said Shantanu Jaiswal, head of research for India at BloombergNEF.

“The Budget is not quite favourable for us. While the government is pushing manufacturing of EVs in India within set guidelines and urging everyone to go eco-friendly, a huge amount of taxes is being slapped on the import of batteries and other important components needed to assemble an EV. All this has delayed the aim of making EVs the future of our country”, says Srinivas Reddy, director of a Pune-based start-up.

While the companies are ready to electrify the automotive market in India, we can say that EV ecosystem is yet to take shape. Though 100 percent electrification seems to be a far-fetched concept, 2020 will in all prospect be a turning point for the automobile market. Over to the EV manufacturers.