Micro-Ceramic Technology: Pushing the Limits of Lubrication

Lubricants are responsible for helping the world move and it is accurately stated that “Lubricants are the blood and lifeline of all machinery” and for this reason lubricants are an important element of study in tribology and machine maintenance. In fact, one of the primary reasons for machine failure is improper and inadequate lubrication, which results in major industrial shutdowns. Industrial shutdowns not only severely affective commercial profitability they also negatively affect the GDP of country, especially, when the demand/availability of high quality lubricants is not adequate and improper lubrication is common. For this reason lubricants are one of the fastest evolving and most researched technologies in the world.

Global industrial growth and increased demands are forcing lubricant evolution as said growth and demand have been accompanied by tightening environmental regulations, depletion of fossil fuels, occupational safety concerns, and tightening mechanical tolerances. These challenges have forced lubrication engineers and researchers to seek and develop a new generation of lubricants with a heavy focus on additive technology. Additives are one of the main building blocks of lubricants and now in an attempt to meet new demands focus is shifting from standard additive to Nano- additives. One of the newest additives being researched, especially for use in greases, is hexagonal boron nitride (h-BN), commonly called micro ceramic or white graphite. Advances in the field of nanotechnology have now allowed lubrication engineers and tribologists to better compare the effects of h-BN to conventional mineral oils and additive packages. h-BN nanotechnology has specifically been improved to a point where h-BN, an environmentally neutral additive, can be emulsified with high quality engine and gear oils. [1]

As mentioned, h-BN has been the focus of several major lubrication studies and its potential has become very clear. Some studies for reference include:

-

Wan et al. [1] dispersed Nano h-BN in SE15W40 and reported a synergistic reduction in friction coefficient of 27.7%-76.7% ̴ in comparison to SE 15W40 without h-BN.

-

Abdullah et al. [2] also dispersed h-BN and Al2O3 in engine oil (SAE 15W40) and reported better friction and wear reduction properties of h-BN dispersed oil as compared to Al2O3 dispersed engine oil.

-

Celik et al. [3] on the wear performances of AISI 4140 in the presence of Nano h-BN dispersed in SAE 10W, a significant wear reduction of 65% and an improvement of 14.4% coefficient of friction was observed. Additionally, it was reported that the surface roughness of the mating pairs were lower in case of h-BN added oil.

-

Pawlak et al [4] dispersed h-BN in grease and compared the tribological properties with a other commercial greases. It was observed that at 5% and 10% vol h-BN dispersed grease samples exhibited less scar depth, surface damage and a better frictional coefficient than the existing commercial greases tested.

-

Kimura, Y., Wakabayashi, T., Okada, K., Wada, T., & Nishikawa, H. (1999). Boron nitride as a lubricant additive. Wear, 232(2), 199–206.

-

Gachechiladze, A., Tsagareishvili, O., Margiev, B., Rukhadze, L., Darchiashvili, M., & Chkhartishvili, L. (2018). Nanopowdered h-BN as a Wear-Reducing Eco-Friendly Material. Handbook of Ecomaterials.

-

Erdemir, A. Solid lubricants and self-lubricating films, Chapter 22, Handbook of Modern Tribology,CRC Press, 2001, pp. 787-818

While the benefits of h-BN are clear it is important to compare it to the existing and common dry lubricants/additives: molybdenum disulfide, Teflon (PTFE), and graphite. It is important to recall that while commonly called “white graphite” h-BN exhibits many different properties than graphite in regard to thermal stability, oxidative stability, and electrical conductivity. The main isolating benefit of h-BN is its high thermal stability. One study by [5] Kimura et al [6] confirmed that h-BN is quite favorable in high temperature applications. After conducting tribological tests, they reported that h-BN dispersed paraffinic mineral oil exhibited better anti-wear properties than the oil without any h-BN particles at high temperatures. While Graphite and molybdenum disulfide provide lubricity up to 400°C h-BN is able to provide added lubricity up to 1000°C [7].

h-BN in Comparison to Moly, Graphite, and Teflon

1. Temperature Stability

a. Micro-Ceramic Max Working Temp 1000°C (1832°F) over 2x higher than molybdenum disulfide, Graphite, and Teflon

| Solid Lubricant | Max Working Temperature |

|---|---|

| Micro Ceramic | Over 1,000° Celsius |

| Graphite | 450° Celsiu |

| Molybdenum Disulfide | 350° Celsius |

2. Oxidative Stability

a. h-BN has an extremely high oxidative stability (over 1000°C in open air)

3. Chemical Stability

a. h-BN is chemically inert and environmentally neutral, making it an ideal oil additive

b. h-BN does not produce toxic byproducts or emissions

4. Insulating properties

a. h-BN has applications as Semiconductors and has a significant insulating property

b. Prevents electrical transfers [ex. electric motors] between conducting metallurgical surfaces by forming a non-conductive film

c. Minimizes raceway damages caused by fluting (Electric Arcing) in rotating components.

5. Adhesion

a. h-BN is highly adhesive to metallic surfaces and forms a protective film on the contacting metal surfaces.

Tribological properties of micro ceramic added into mineral oil:

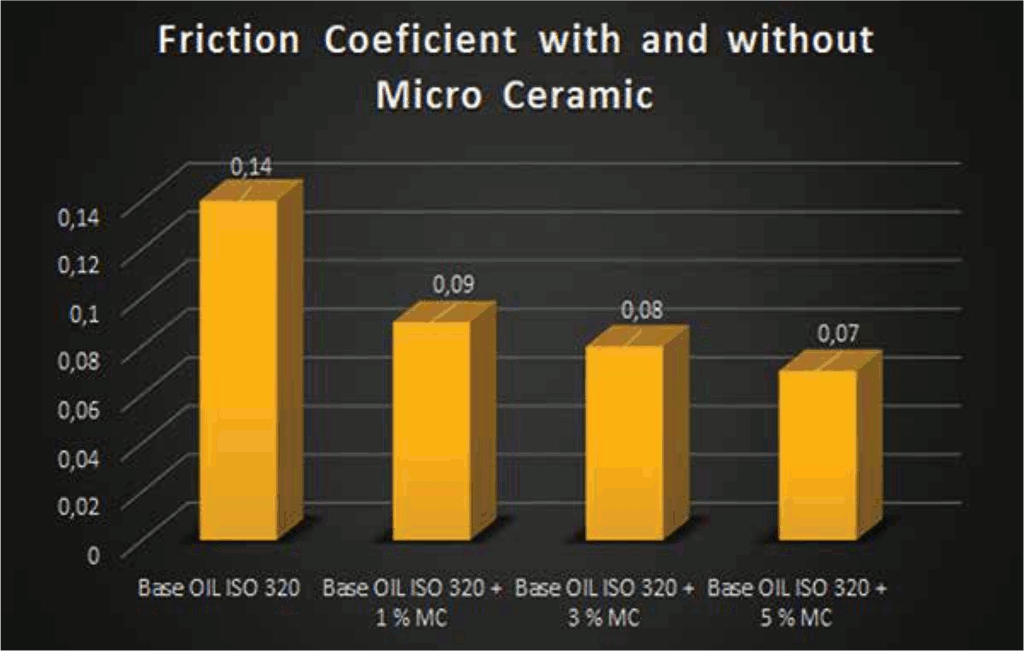

Figure 1 shows the friction coefficient of micro ceramic (h-BN) dispersed in ISO 320 base oil. Nearly a 50% reduction in friction coefficient was observed with the presence of 5% micro ceramic particles. Tribological studies of these Micro Ceramic Nano sized solid lubricants as an additive for greases exhibited a reduction in wear by 30 – 70 % at various loads. Further results obtained using a 4 ball bearing and a pin on a disc tribometer showed a reduction in wear scar of up to 20 % proving micro ceramics ability to reduce wear and withstand the stringent demands of new mechanical equipment. The advantages of h-BN (micro ceramic) as a grease additive are especially clear in high temperature applications where greases are used and commonly fail to provide adequate lubrication.

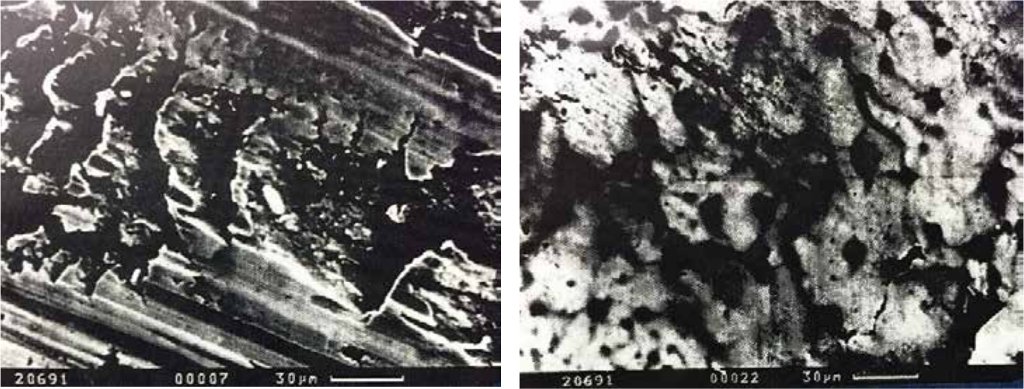

The high affinity of the micro ceramic particles and their ability to form stable lubricity films under extreme pressures aid in reducing the friction and wear between the contacting metal surfaces. Figure 2 indicates the magnified bearing surfaces treated with/without micro ceramic dispersed oil. With boring and honing the surfaces still only have about 20-25% surface to surface contact, which results in both wear and friction (Figure 2a). However, Figure 2b shows how micro ceramic adheres to the porous surface structure and increases surface to surface contact. With the introduction of a micro ceramic additive, surface to surface contact is increased to nearly 75-85% and friction and wear are reduced as the surface contact is h-BN on h-BN, not metal on metal.

Why the structure of h-BN is so effective?

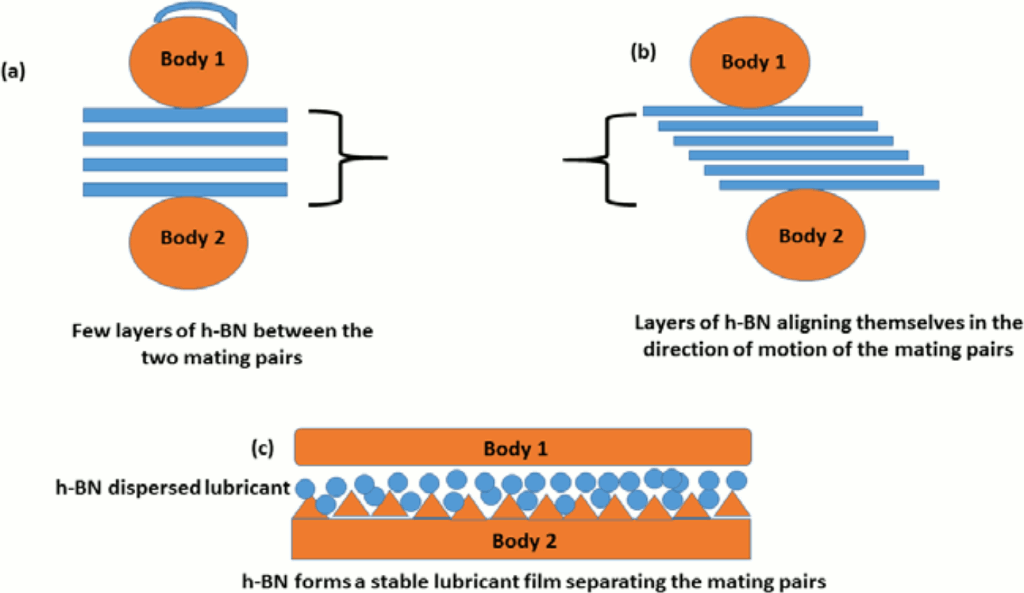

The molecular structure of h-BN is that of layered lattice, covalently bonded hexagonally with the different layers having weaker Van der Waals bonds. The two types of bonds composing h-BN make it a dynamic lubricant. The covalent bonding holding each layer together makes h-BN extremely durable and able to withstand high pressures and high temperatures. The weaker Van der Waals bonds are not as durable as covalent bonds, however, they benefit h-BN by allowing it to “shed” layers and fill porous metal surfaces without changing surface dimensions. The weaker Van der Waals bonds also allow layers of h-BN to slide past one another freely with very minimal resistance. This is shown visually in the tribological pairs as seen in Figure 3a and Figure 3b. Further to that, h-BN forms a stable lubricant film on the tribo pairs and provides low friction during operation (Figure 3c). This, in combination with its high thermal rating make h-BN an excellent additive for greases, especially in industrial applications where a wide temperature range is experienced. The potential of h-BN as an industrial grease additive is further confirmed by Pawlak et al [4]