When and How to Adjust a Load-sensing Hydraulic Pump

Variable-displacement pumps are used in hydraulic systems where the flow requirements vary. This usually means the system has several actuators and, depending on the current cycle of the machine, the number of actuators moving at a given time will fluctuate. The most common type of variable-displacement pump is the pressure-compensating pump.

Pressure-compensating Pumps

Pressure-compensating pumps are designed to deliver only the amount of flow required by the system to maximize efficiency and avoid heat generation. The compensator is adjusted to a pressure somewhat higher than that required to move the system’s heaviest load.

A pressure-compensating pump will deliver its maximum flow until the system pressure reaches the compensator setting. Once the compensator setting is reached, the pump will be de-stroked to deliver only the amount of flow that will maintain the compensator setting in the line.

Whenever more flow is demanded by the system (such as would occur when an additional actuator begins to move), the pump will increase its stroke to meet the new flow demand. Whenever the system flow needs to decrease (such as when one or more actuators are stopped), the pump stroke is reduced.

When the system is stopped completely, the pump stroke is reduced almost to zero. It will stroke only a very small amount or whatever is required to maintain the compensator setting in the line, overcoming any system bypassing or leaks. While a pressure-compensating pump is efficient, the standby pressure remains high.

Adjusting Pressure-compensating Pumps

Adjusting a pressure-compensating pump is quite simple. With all flow blocked and the system idle, the compensator valve is adjusted to the desired pressure. However, some pressure-compensating pumps have two valves mounted on the pump body.

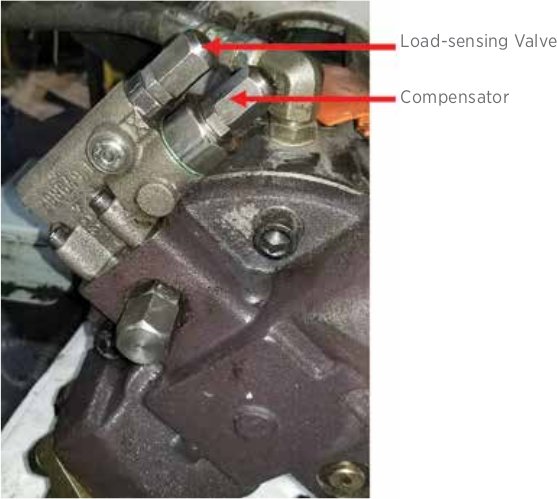

Adjusting a pressure-compensating pump is quite simple. With all flow blocked and the system idle, the compensator valve is adjusted to the desired pressure. However, some pressure-compensating pumps have two valves mounted on the pump body.

The two adjustments can look nearly identical. This type of pressure-compensating pump is called a load-sensing pump. The second adjustment is called either a “load-sensing” valve or “flow-compensator” valve.

A load-sensing pump is designed to reduce its pressure to a much lower standby level whenever the system is idle. This can conserve energy and reduce heat and wear in systems that spend a significant amount of time in an idle condition.

The two separate pressure adjustments allow setting the compensator valve to the required maximum system pressure and the load-sensing adjustment to a much lower standby pressure.

Whenever the system is moving a load, the high-pressure adjustment limits the system pressure. For instance, as a cylinder is extended, pressure in the system will build as necessary to move the load. Eventually, the cylinder reaches the end of its stroke, and flow is blocked.

When the flow is blocked in this fashion, the system pressure can build no higher than the setting of the compensator, but until another load is to be moved, there is no need for the system pressure to be kept so high.

When the flow is blocked in this fashion, the system pressure can build no higher than the setting of the compensator, but until another load is to be moved, there is no need for the system pressure to be kept so high.

Most load-sensing systems have a pump-loading directional-control valve of some sort that can place the system in an idle condition until it is necessary to move another load. When the pump-loading valve is shifted, the system pressure drops to the much lower load-sensing valve setting.

A load-sensing valve usually is smaller than the compensator valve and typically mounted directly on top of the compensator. The compensator valve is closer to the pump. The load-sensing valve is factory preset and normally does not need to be adjusted during the initial pump setup. In most pumps, the factory preset is approximately 200-300 pounds per square inch (psi).

The most common reason to adjust a load-sensing valve is because someone unfamiliar with the pump has mistakenly attempted to set the maximum system pressure by adjusting the load-sensing valve instead of the compensator. This not only can result in unstable system pressure but in some cases can also void any warranty on the pump.

The most common reason to adjust a load-sensing valve is because someone unfamiliar with the pump has mistakenly attempted to set the maximum system pressure by adjusting the load-sensing valve instead of the compensator. This not only can result in unstable system pressure but in some cases can also void any warranty on the pump.

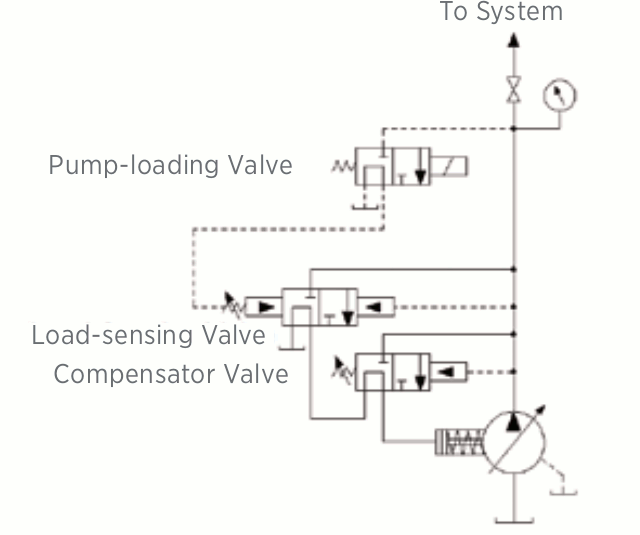

A typical configuration of a pressure-compensating pump is shown in Figure 1. A pump-loading valve is used to determine whether the system is idle or prepared to move a load. The pump-loading valve is de-energized whenever the system is idle.

Pilot pressure on the left-hand side of the load-sensing valve is then released to the tank. The pilot line on the right-hand side of the load-sensing valve is connected to the pressure line at the pump outlet. System pressure shifts the load-sensing valve and directs pressure to reduce the pump stroke so that system pressure drops to the load-sensing setting of 300 psi, as illustrated in Figure 2.

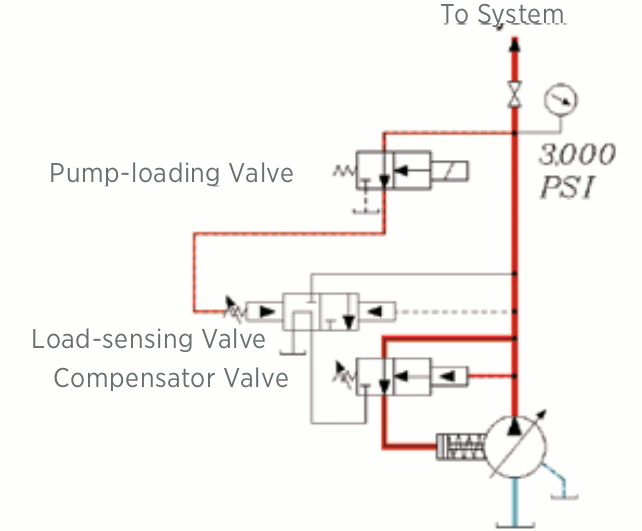

When a load is to be moved, the pump-loading valve is energized. This directs pilot pressure to the left side of the load-sensing valve, keeping it from shifting. System pressure shifts the compensator valve to de-stroke the pump exactly the amount necessary to limit system pressure to the compensator setting, 3,000 psi as shown in Figure 3.

When a load is to be moved, the pump-loading valve is energized. This directs pilot pressure to the left side of the load-sensing valve, keeping it from shifting. System pressure shifts the compensator valve to de-stroke the pump exactly the amount necessary to limit system pressure to the compensator setting, 3,000 psi as shown in Figure 3.

To make the pressure settings, always adjust the load-sensing valve first. The pump should be deadheaded by closing the manual hand valve. With the pump-loading valve de-energized, pressure will build only to the current setting of the load-sensing valve. Adjust the load-sensing valve to the desired pressure.

Once the load-sensing valve is set, energize the pump-loading valve. System pressure will then build to the current compensator setting. Adjust the compensator to the desired setting. Open the manual valve, and the system can be placed back into service.

There are several variations of this design. Sometimes a throttle valve will be used to determine if a load is available. The pressure drop that results when oil moves through the throttle valve signals the need for higher system pressure.

Another common variation is to use the load-sensing valve in conjunction with a proportional relief valve connected in series. Standby pressure will then be determined by the sum of the load-sensing pressure and the electronically controlled setting of the proportional relief.

In more complex arrangements such as this, hand valves should be installed that can be opened or closed to deadhead the load-sensing valve and also to release its pressure to the tank to enable setting the pressure.