You Earn What You Learn

2020 will be known as the year when the world was forced to shelter to protect human lives and to stem the spread of a potent, invisible enemy ... COVID-19. The dire economic consequences of this virus are affecting us too. Is it possible there is a silver lining?

Some have used this life-disrupting period to find and leverage key opportunities, both personal and professional. This includes planning and making ourselves, our careers and businesses ready for the time when we emerge at the other end of chaos.

Honestly, there could hardly be a better time to prepare and adapt for the future that lies ahead. View it as a time to reload and recalibrate. We are transitioning through both forced and necessary changes to a new normal. Things will never be quite the same. The opportunity is there to become stronger and wiser. Of course, this includes the field of lubrication and reliability.

Training organizations worldwide are scrambling to advance educational options that align with this new normal. These include various forms of distance and e-learning that include virtual and mobile device deliverables. Lack of mobility from this pandemic does not have to mean a lack of productivity from lost time and wasted resources. It is our choice to be people of action and purpose. More now than before.

What follows are common questions and challenges related to the concept of training and its true value relative to actual and perceived costs. Is training a want or a need? Are the benefits real or imaginary? What is the tangible connection of training to machinery reliability, maintenance costs, productivity and profitability? Read on...

1. Question: What if We Train Our People and They Leave?

Answer: What if We Don't Train Our People and They Stay!

Noria is a training organization, among other things. Since our inception, we have heard people question the wisdom of training and certification. One common argument is the concern that a trained workforce would result in higher turnover (employees marketing their new skills). From my experience, this is more myth than reality.

People have an innate need to do good work. When people do bad work, they feel bad about themselves and their job. They look for other job opportunities. Conversely, when people do good work, they feel good about themselves and their job. Training enables good work, job satisfaction, and workforce retention.

New call-to-action

Additionally, job skills, knowledge and good work propagate. People teach each other. This knowledge permeates and lasts long after the originally trained persons have moved on through attrition or retirement. This is especially true when advanced training concepts are used to update task procedures and tools. When training leads to sustained change with real value, then training should be viewed as an asset. After all, the definition of an asset is something that has future value.

On the other hand, without transformational training, old-school ideas and methods remain entrenched. Although their intentions are good, the teachings of many old-timers propagate the use of substandard methods and impair opportunities for change and improvement. Sadly, this induces and sustains a state of unreliable asset performance and high maintenance costs.

Training both impacts and attracts good quality employees. Imagine that your people leave, what will they say about their experience at your plant? Let's face it, social media is a megaphone. If people leave do you want the message to be "they didn't develop or care about their people," or "it was one of the best experiences of my career if you can get a job there, do it!"

2. Training Drives Overall Workforce Effectiveness (OWE)

Most of us have heard of overall equipment effectiveness (OEE). This widely used metric is the arithmetic product of three factors: machine availability, machine performance, and product quality. It's a great "big picture" snapshot of a plant's general reliability program.

Improving OEE requires improving one or more of the three factors. Looking at each of these three factors, from an operations and maintenance viewpoint, requires improvement in such things as work methods, skills, tools, culture, etc.

Workforce training seems to drive most anything that is desired, including OEE improvement. We do what we learn and understand; the what, the how, the why, the when, the where. The opposite is equally true. In fact, you may have heard of overall workforce effectiveness (OWE) (aka overall labour effectiveness).

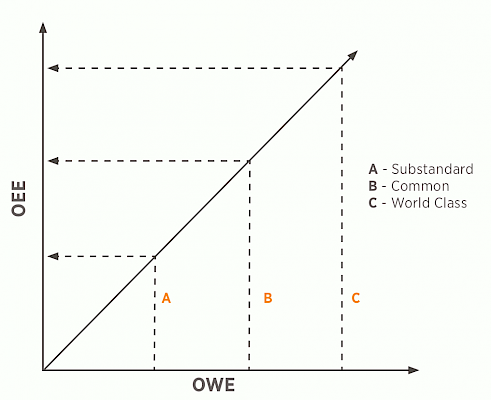

Like OEE, the same three factors apply for OWE. Moving the needle on OEE means we must move the needle on OWE; they are in lock-step (Figure 1). Look at these OWE factors in the context of people skills, awareness, and standardized work:

Availability. A well-run maintenance program may also be known as precision maintenance and planned maintenance. This is the opposite of breakdown maintenance. Maintenance personnel are available because of planned work, not emergent work, and doing the right things right, the first time every time. Under a planned maintenance program with skilled workers, increasing workforce bandwidth does not need to require increasing your workforce headcount or even hours worked. Precision and efficiencies make time and free up resources.

Performance. Effective, up-to-date training can increase performance by improving the skills that directly impact the productivity of work performed. A skilled maintainer, technician, millwright, analyst, operator, etc. should know the correct procedure, the correct tools, etc. to perform a task quickly and efficiently. You've heard of the Optimum Reference State. Doing the optimum is enabled by knowing the optimum (through training and standardized work).

Quality. While performance is productivity related, quality influences the sustainability and effectiveness of work performed. There are right and wrong ways that affect performance and right and wrong ways that affect quality. Precision lubrication relates to the precise selection of lubricants, the right amount, the right frequency, the right method, the right location, the right cleanliness, the right inspection method, and so much more.

There are so many choices that technicians and operators face in performing maintenance tasks. The same is true with reliability and lubrication engineers. We don't know these things by instinct. The life expectancy of lubricants and machinery components directly relates to the choices we make and the choices we don't make. For instance, let's connect this to oil analysis - who in your organization is going to answer these questions and, most importantly, get it right?

- Right machines to sample

- Right sampling frequency

- Right sampling location

- Right sampling procedure

- Right lab selection

- Right tests to perform

- Right alarms and limits

- Right data interpretation strategy

Training drives change in workforce availability, performance and quality. A penny saved - by not investing in training - is not a penny earned, but rather hundreds of dollars forfeited all for the quest of a penny.

3. The "Unlearning" Component of Real Education

Not so many years ago, people put particles of cork and wood pulp in automobile engines because they believed it improved lubrication and reduced noise. This is just one example of many outlandish ideas that still endures in the lubrication world. You've probably heard a few yourself. You know what I mean, those ridiculous claims about lubricants and lubrication, that over time, evolved into urban legends.

Much of this folklore has surfaced from a single exaggerated or misinterpreted fact and spread from there. Many stories have been scientifically discredited but still linger in the lubrication community.

For instance, can you distinguish fact from fiction from the statements in this list?

-

Although more expensive, engine oils make superior hydraulic fluids due to the more advanced additive packages and base oils.

-

Most grease products readily absorb water in service, which is actually a design feature to improve lubrication.

-

Sludge in the bottom of a sump is harmless unless disturbed.

-

Lubricants are considered clean if you don't see particles or feel a gritty texture.

-

Most all gear oils lose critical additives if filtered below 10 microns.

-

Grease is better than oil at controlling friction and wear in rolling-element bearings. This is the reason far more bearings are lubricated with grease compared to oil.

-

Oil analysis is generally a waste of time and resources for lubricants coming from small compartments (e.g., less than 4 liters).

-

Particle counting by oil labs is unnecessary for diesel engine lubricants.

-

The capture efficiency of oil filters always gets better over time in typical service.

-

The best way to control water contamination in industrial equipment is to keep the oil hot.

-

Different brands of quality turbine oils can be mixed safely, without loss of performance.

Of the 11 statements, how many did you think were true? Perhaps five or eight? Each of these statements have been reported to be true by people who claimed they knew their facts. The reality is that none of these statements are true. Even worst, today, people still make maintenance decisions based on many false assumptions and outdated information. Training is an excellent means to clear up misconceptions of what's fact and what's fiction.

4. Training Fosters a Nurturing and Productive Maintenance Culture

Warren Buffett once said, "Confidence is like oxygen. When you have it, you don't think about it. However, when it's gone, you know it immediately, and you want it back." Culture is much the same way.

Culture is a critical plant asset. Some plants have it, and many plants do not. Culture decides who we hire and who we don't. Culture advocates continuous learning and exceptional job skills. Culture says yes to right tools, machine improvements and right procedures. The culture celebrates proactive successes and purges reactive maintenance habits. The list goes on.

A prosperous plant culture is a learning culture. Education, when effective, takes people out of their comfort zone. It not only builds intellectual capital but, over time, fosters a behavioural desire to do good, quality, sustainable work.

It also builds team loyalty and dedication to achieving business goals. People learn differently, so don't assume knowledge is only acquired in a classroom. Certification instils pride and should be the capstone to each learning stage by providing visible recognition of skill competency.

Let's get trained!

What great companies do

By Chris Christenson Director of Education, Noria

As I have been ‘sheltering in place,’ I am reminded of what successful companies do in times like this; they invest! I believe Tim Collins discovered this concept when interviewing company leadership for his book, Good to Great. He identified that great organizations use downturns to invest in the process and their people and prepare for the future.

We have quickly developed our Live Online Training courses as an excellent solution to help you invest in your teams at this time.

Don’t let current events prohibit investment in your team. For all the challenges that event-based training can pose for learners and organizations, live online training provides convenient flexible, and results-oriented options to solve unique situations. As we have developed the live online training, we considered these advantages:

- Multisite access – Train team members in multiple locations, even in their homes.

- No travel costs – Training comes to you.

- Close to the plant – Keep your team available; flexible options allow team members to connect with the daily activity of the plant while attending a live course. Training can be scheduled once a week, multiday training.

- Public training online – Monthly hosted events are available for smaller groups of students

- Interactive improves engagement – Each live online training, includes demonstrations, interactive polling, chat and question-and-answer sessions.

Invest in your team now because when the world gets going again, you will be ready!