Sustainability through Transparent Girth Gear Lubricants

The Ecological Footprint and Handprint

Emerging measurements of human impacts on the planet are gaining mainstream credibility. The Ecological Footprint has been developed by an international coalition called the Global Footprint Network as a measure of our use of the planet’s biocapacity. Te Ecological Handprint measure seeks to build upon the Footprint measure and reframe the concept of sustainability by looking not just at ecological impacts but also ensuring sustenance for those in need.

The ‘ecological footprint’ of humanity is gaining attention as a way of measuring the amount of resources we consume and the waste we produce against the planet’s ability to produce those resources and ‘digest’ our waste. Currently, every year we are exceeding the planet’s ‘biocapacity’ to perform these functions by about 50%.

The ecological footprint calls this an ‘overshoot’. In 2014, overshoot day – that is the day we used up 100% of the planet’s biocapacity – fell on August 19th. But in 2016 we will have reached overshoot day even earlier, on August 8. We use more ecological resources and services than nature can regenerate through overfishing, overharvesting forests and emitting more carbon dioxide into the atmosphere than forests can sequester.

Ecological Handprints bring a social dimension to the issue of measuring our Footprint and recognize the need for people’s needs to be met as part of the sustainability agenda. This concept suggests that we can achieve a high level of human development without compromising the ecological systems upon which all life depends.

Cement Plants

Cement Plants

Cement plants have cement mill for raw material grinding and further clinker formation, the Kiln girth gear drive for clinker formation. Typically these drives are rotated with the help of pinion and girth gear. Maintaining pinion and girth gear in good condition is a must for uninterrupted running of the plant. But maintenance and monitoring do not only help sustain these pinion and girth gear. Here lubrication plays a vital role in enhancing the life of girth gear drives.

Problem

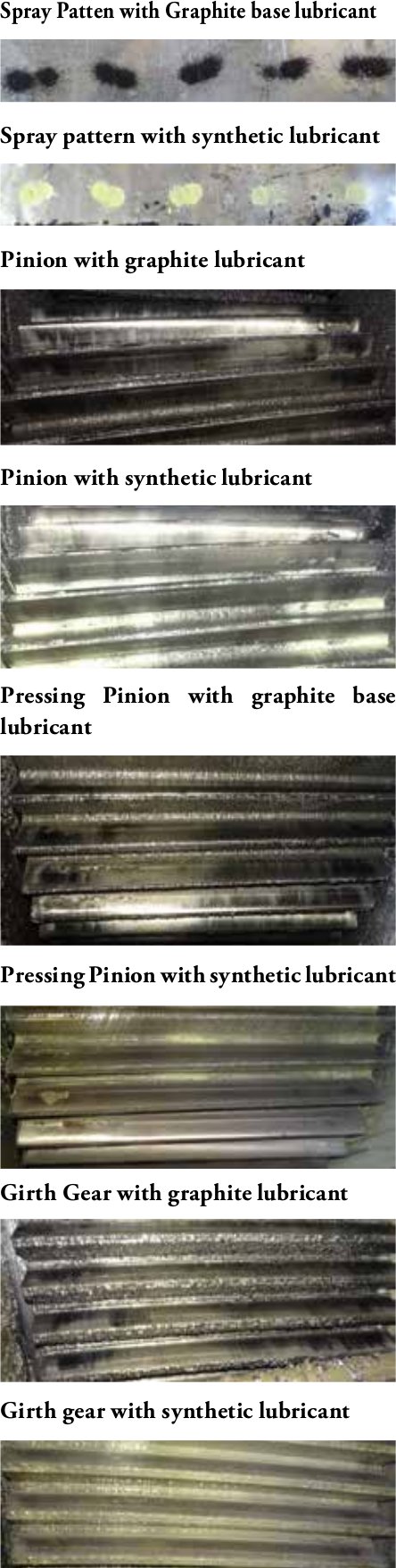

Primarily, girth gear drives were running with graphite as a main constituent in the grease, In the longer run, with use of graphite based open gear lubricants, pitting, scuffing, root step, side fins observed on gear and pinion tooth flank because the gear is mostly in the mixed friction zone. In this condition, gear requires additional work like root step removal, side fins removal, polishing of the teeth etc.

To carry out these jobs, the stoppage of Mill or Kiln is required and production hours are also lost. A lot of safety guidelines and formalities need to be furnished while carrying out these jobs, this adds on the work to already occupied Safety Officers. Carrying out these jobs need lots of cleaning activity to remove the grease manually, manpower, skilled manpower, grinding tools are required.

Solution

Now with new synthetic transparent lubricants, the wear is almost negligible because of the higher lambda values and the rotating parts being in Elasto Hydrodynamic Lubrication (EHL). You can see the tooth flank clearly, the amount of lubricant required for running the equipment is almost half of the graphite based lubricants. Less wastage and a substantial increase in the life of Girth Gear.

Sustainability

This helps us in minimizing footprint and maximizing handprint.

Case Study on Cement Mill Girth Gear Lubrication

Abstract

Te report emphasises on the condition of Cement Mill open gear drive after putting Synthetic Lubricant. In comparison with our Graphite based product. Here we will try to present the condition of the open gear drive in terms of temperature difference, tooth flank condition and optimization of grease consumption from day one.

Equipment Details

Gear OEM: Fuller

No. of Pinion: 2

Tooth Flank Width: 750 mm

Lubrication System: Spray (2 X 5 Nozzles)

Lubrication System OEM: Lincoln

Helios ( Pneumatic operated)

Objective

Enhancing the Girth gear life with Introduction of transparent Open Gear Lubricant

Enhance the life of Pinion and Girth Gear.

Tooth flank condition is clearly visible.

With the higher viscosity, it was possible to Optimize Consumption from existing 14.39 Kg per day to 6.5 Kg per day with stable parameters.

Vis-a-vis it is observed that with synthetic lubricant, measurable parameters Temperature, Vibration, Tooth flank temperature wrt Shell temperature ambient temperature observed stable.

No further propagation observed on the tooth flank and tooth flank condition is clearly visible, which helps the customer in monitoring the condition of the tooth flank.

Efforts / Major Activities to achieve the objective

To fulfil our objectives as mentioned above we have taken these steps:

Consumption optimization (Grease) without a change in the condition of the drive

Condition monitoring at regular intervals & optimization

Stable parameters even half of the lubricant consumption

Saves money

Easy inspection

Less disposal helping in minimizing footprint and maximizing handprint

Help reduce CO2 emission

| Date | DE to NDE 1 | DE to NDE 2 | DE to NDE 3 | DE to NDE 4 | DE to NDE 5 | ∆ T |

|---|---|---|---|---|---|---|

| 06.05.2019 | 55.2 | 55.1 | 55.9 | 56.4 | 56.5 | 1.4 |

| 07.05.2019 | 51.2 | 51 | 51.5 | 52.1 | 52.2 | 1.2 |

| 07.05.2019 | 53.1 | 52.8 | 53.6 | 54.1 | 54.2 | 1.4 |

| 08.05.2019 | 52.8 | 52.6 | 53.2 | 53 | 52.4 | 0.8 |

| 25.05.2019 | 52.3 | 52 | 52.6 | 52.7 | 52.2 | 0.7 |

| 25.05.2019 | 56.1 | 56.4 | 56 | 55.4 | 55.8 | 1 |

| 26.05.2019 | 52.1 | 53.6 | 54.1 | 53.5 | 53.3 | 2 |

| 25.06.2019 | 53.9 | 53.6 | 53.5 | 53.4 | 52.5 | 1.4 |

| 26.06.2019 | 53 | 52.9 | 52.6 | 52.5 | 51.6 | 1.4 |

| 18.07.2019 | 52.7 | 53.6 | 54.2 | 53.7 | 53.8 | 1.5 |

| 19.07.2019 | 52 | 53.2 | 53.3 | 52.8 | 52.3 | 1.3 |

| 20.07.2019 | 53.1 | 53.5 | 53.6 | 52.6 | 52.1 | 1.5 |

| Date | DE to NDE 1 | DE to NDE 2 | DE to NDE 3 | DE to NDE 4 | DE to NDE 5 | ∆ T |

|---|---|---|---|---|---|---|

| 06.05.2019 | 53.8 | 54.7 | 56.2 | 57.5 | 57.9 | 4.1 |

| 07.05.2019 | 49.5 | 50.2 | 51.2 | 52.3 | 52.7 | 3.2 |

| 07.05.2019 | 49.6 | 50.7 | 52.6 | 54.2 | 54.9 | 5.3 |

| 08.05.2019 | 50 | 51.1 | 53.6 | 54.4 | 54.6 | 4.6 |

| 25.05.2019 | 52.5 | 51.8 | 51.8 | 51.2 | 50.1 | 2.4 |

| 25.05.2019 | 55.5 | 54.9 | 55.8 | 54.5 | 53.3 | 2.5 |

| 26.05.2019 | 53.9 | 53.6 | 54.1 | 53.1 | 53 | 1.1 |

| 25.06.2019 | 51.3 | 50.6 | 50 | 49.6 | 48.9 | 2.4 |

| 18.07.2019 | 53.3 | 52 | 53.2 | 51.8 | 50 | 3.3 |

| 19.07.2019 | 52.3 | 50.7 | 49.3 | 49.8 | 48 | 4.3 |

| 20.07.2019 | 52.7 | 52.3 | 52.4 | 51.1 | 49.5 | 3.2 |

| Date | DE to NDE 1 | DE to NDE 2 | DE to NDE 3 | DE to NDE 4 | DE to NDE 5 | ∆ T |

|---|---|---|---|---|---|---|

| 06.05.2019 | 51.6 | 52 | 52.3 | 52.6 | 53.3 | 1.7 |

| 07.05.2019 | 48.8 | 49.8 | 49.8 | 48.8 | 49.9 | 1.1 |

| 07.05.2019 | 48.2 | 48.5 | 48.8 | 48.8 | 49.5 | 1.3 |

| 08.05.2019 | 48.1 | 48.5 | 48.5 | 48.5 | 48.6 | 0.5 |

| 25.05.2019 | 49.6 | 49.3 | 49.2 | 49.3 | 49 | 0.6 |

| 25.05.2019 | 52 | 52.1 | 52.5 | 52 | 51 | 1.5 |

| 26.05.2019 | 49.8 | 50.1 | 50.5 | 50 | 49.7 | 0.8 |

| 25.06.2019 | 50.1 | 50.0 | 49.7 | 49.4 | 48.5 | 1.6 |

| 26.06.2019 | 50.0 | 49.9 | 50.0 | 49.3 | 49.0 | 1.0 |