Ask the Experts

“What are lubricant churning and bearing torque, and how do they affect gears, bearings and the lubricant?”

“What are lubricant churning and bearing torque, and how do they affect gears, bearings and the lubricant?”

Bearings and gears require a certain amount of force to begin turning and to continue turning once they are set in motion. The measure of this force is commonly referred to as torque. Running torque is usually less than starting torque. These forces are variable depending on several parameters.

Lubricant churning is one of the more common factors that affect both bearings and gears. It occurs when the bearing or gear must churn through the lubricant as it performs its regular task. The majority of these machines are splash-lubricated, which means they must operate at the proper lubricant level to be able to lift and splash lubricant to all surfaces inside the machine. This is where lubricant churning can become an issue.

If the lubricant level is too high, either because too much oil has been added or the bearings have been over greased, the machine must work harder to push through the added lubricant. This is the basis of that churning condition.

It can be compared to walking along the beach. If you reach ankle-deep water, it is still fairly easy to move (equivalent to running torque). However, if the tide comes in or you venture out into deeper water, it becomes much more difficult to walk. This requires you to work harder and causes you to tire out quicker.

The same thing happens to a machine when the lubricant level is too high. It works much harder to push through the added lubricant, which results in higher operating temperatures, decreased efficiency and a reduction in the life of both the lubricant and the machine.

Besides the lubricant level, another variable is the lubricant being used. Since the most important physical property of a lubricant is viscosity, the proper viscosity must be selected according to the speed, load, temperature and general running conditions of the machine. If the viscosity is too thin, then excess friction due to metal-on-metal friction is generated, causing machine wear and premature failure. If the viscosity is too thick, this leads to viscous drag, which causes very similar issues as having a lubricant level that is too high. Neither of these situations is desirable for the equipment.

By choosing the right lubricant as well as ensuring the appropriate lubricant level, you can give your equipment the best chance for error-free operation.

“I would like to perform optical particle analysis. Do you have any suggestions or recommendations for this? I have some particles and a microscope, but I am looking for information that describes this oil analysis method so I can try it for myself.”

“I would like to perform optical particle analysis. Do you have any suggestions or recommendations for this? I have some particles and a microscope, but I am looking for information that describes this oil analysis method so I can try it for myself.”

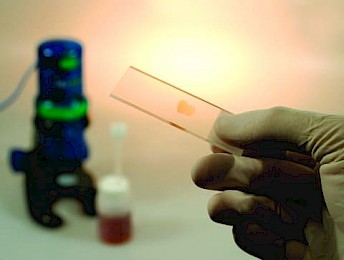

Implementing a procedure to characterize contaminant particles found in lubricants and becoming proficient in this technique will require considerable study and practice. First, you should set goals for the analysis, like determining the particle size, metal type and wear failure modes. This information can be obtained from a particle characterization sample such as a ferrogram, filtergram or patch test.

With a ferrogram, wear particles are captured on a glass surface, which is placed in a magnetic field. For this reason, it has a bias toward ferromagnetic particles from iron or steel, but it also can capture non-ferrous particles. This is frequently referred to as analytical ferrography. Engines, most gearboxes, rolling-element bearings and most hydraulics are among the types of equipment that are most likely to produce magnetic wear particles.

A ferrogram is easy to heat-treat for identification purposes and has excellent transmission of bottom light. Unfortunately, the particles tend to pile up, and the preparation equipment is generally more expensive.

On the other hand, a filtergram has no bias toward ferrous particles and is easy to prepare. The necessary hardware is also less expensive. However, it is more difficult to distinguish metal types and to prepare two membranes (one ferrous and one non-ferrous). Special patches are also required for heat-treating, and the transmission of bottom light is not as effective. Equipment with critical non-ferrous frictional surfaces include worm gears, stainless-steel machinery and turbomachinery with bronze or Babbitt bearings.

A patch test, also called patch ferrography, can be used to collect all types of solid particles in oil since the fluid is simply filtered through a patch or paper. With this method, there is no bias toward a ferromagnetic element or metallic debris. After particle samples are taken and analyzed with a microscope, it is possible to heat the sample to observe colour changes in the particles. This helps to identify the metal type. This procedure is typically run in ferrograms.

For reference, be sure to consult the corresponding ASTM methods (D7684-11 and D7690-11). Noria’s oil analysis training courses can also provide more information about these techniques and the value of oil analysis.