Lubricant Packaging: New and Upgraded Systems

The packaging industry is turning out to be one of the dominant sectors in India. Rapid changes are taking place inefficient packaging systems development globally. Lubricant packaging includes all kind of packaging which are used in handling, storage and transportation of lubricants. Lubricants are used in almost all major heavy-duty industries including oil & gas, metal fabrication, power generation, automobile, etc. The packaging depends on the type of product and the industry it serves.

Lubricant packaging companies are focusing on mounting their business through mergers and acquisitions. More than 600 types of packaging machines and equipment are manufactured by small and medium-sized enterprises (SMEs). This emerging opportunity for the packaging industry is giving rise to new visions and prospects.

Key Points

-

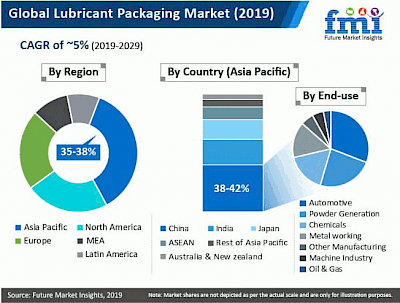

The global lubricant packaging market size was US$ 9 billion in 2018. The lubricant packaging market is expected to grow at a compound annual growth rate (CAGR) of 5% during the period of 2019-2029.

-

The lubricant packaging in the automotive industry is expected to account for fairly high sales.

-

Collectively, Asia Pacific and Europe are predicted to account for a 60% revenue share in the lubricant packaging market, by the end of 2029.

-

The Middle East & Africa and other developing countries will continue to hold a high potential for the growth of the lubricant packaging market. An increase in trade between developed and developing economies for industrial oil and other fluids are probable to drive the lubricant packaging market growth.

Global Lubricant Packaging Market: Regional Analysis

Global Lubricant Packaging Market: Regional Analysis

The lubricant packaging market is highly competitive. The players in this market have a multinational presence with an extensive distribution network. Some of the market contenders include Glenroy, Inc., Scholle IPN, Duplas Al Sharq LLC, Mold Tek Packaging Ltd, CYL Corporation Berhadcompany and Balmer Lawrie & Co. Ltd. Expansion and merger strategies are adopted by key players to grow their business and product portfolio. Product developments and new product launches are also among the important trends followed by prominent lubricant packaging manufacturers.

In the past, Asia Pacific led the overall lubricant packaging market size, in terms of value and volume. It is poised to witness tremendous growth during the forecast period (2019-2029) due to steadily increasing demand from the mining, machining, metal forming and plastics industry mainly in India and China. The Asia Pacific will continue to be the highly lucrative region for the lubricant packaging market throughout the forecast period as per the report published on futuremarketinsights.com. Online retailing of consumer lubricants is another evolving trend that is most visible in China with established portals like JD.com and Alibaba. Continuously progressing and growing automobile industry with rapid technological changes in North America will also have a positive influence on the regional lubricant packaging market.

| By Packaging | By Lubricant | By End-user |

|---|---|---|

|

|

|

Pitfalls and Challenges

The companies in the packaging industry are facing numerous challenges of handling customer preferences, sales competition, fluctuating prices of feedstock used for packaging products manufacturing and product quality endurance. Environmental safety concerns have impacted the growth of the plastic-based packaging materials market and there was a significant blow to the industry due to the government regulations and policies in favour of ecological issues.

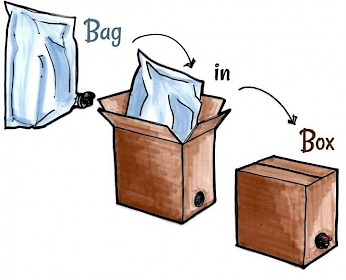

However, the ever-changing aspects of the industry, the introduction of eco-friendly packaging products and innovation has uplifted the industry and today the Indian market is competing to the global standards. Lubricant packaging manufacturers are shifting towards flexible packaging format, due to its affordability and convenience. Stand-up pouches and bag-in-box are gaining more attention because these are lighter than rigid plastic bottles and consume 60 per cent less plastic.

Trends in Automotive and Industrial Lubricant Packaging

1) Shell introduced colour-coded bottles for Aeroshell Piston Engine Oils which made it easier to recognize and choose the product with confidence. The benefits of new packing are as follows:

1) Shell introduced colour-coded bottles for Aeroshell Piston Engine Oils which made it easier to recognize and choose the product with confidence. The benefits of new packing are as follows:

- New bottle design – Color-coded by-product benefits for easy recognition.

- New back label design – Consumer-friendly back label, new multipage pull-out covering up to 14 languages.

- New cartons and case configuration.

Shell also introduced Ecobox; a motor oil container that reduces plastic waste. Using the Ecobox plastic liner results in 89 per cent less plastic landfill waste and the carton is fully recyclable.

2) Back in 2012, Wichita-based Universal Lubricants—now a subsidiary of PetroChoice—was thought to be the first United States company to introduce retail motor oil in a pouch. Universal Lubricants manufactures the ECO ULTRA oil pouches using a 6-mil, 3-layer barrier construction of polyester, nylon, and linear low-density polyethene (LLDPE). Which are:

- Lighter in weight enabling freight cost reductions. Unfilled flex-packs are equivalent to 26 truckloads of unfilled rigid plastic containers.

- Translating into a significant reduction in fuel consumption, road emissions, fleet maintenance, and operation costs. Another relatively new concept is the bag-in-a-box, a single-use cardboard container that houses a plastic bag filled with the product. Recognized for being easy to stack, store and ship, these use far less material than the equivalent-sized rigid plastic bottles, significantly helping to reduce landfill waste. Universal's bag-in-a-box package is a simple idea with big benefits.

3) Valvoline introduced a new stand-up pouch for two varieties of its synthetic gear oil. Valvoline worked with Hammer Packaging to design the FlexFill bag, which is a lamination of PET/nylon/low-density polyethene, with the layers chosen for printability, strength and sealability, respectively. This FlexFill bag made changing of synthetic gear oil easier and also providing a more flexible, less wasteful automotive DIY (Do-It-Yourself ) experience.

3) Valvoline introduced a new stand-up pouch for two varieties of its synthetic gear oil. Valvoline worked with Hammer Packaging to design the FlexFill bag, which is a lamination of PET/nylon/low-density polyethene, with the layers chosen for printability, strength and sealability, respectively. This FlexFill bag made changing of synthetic gear oil easier and also providing a more flexible, less wasteful automotive DIY (Do-It-Yourself ) experience.

4) SK Lubricants manufactured eco-friendly containers from recycled waste plastics by conducting research with SK Innovation’s Chemical Research Center and SK Global Chemical, an affiliate of SK Innovation’s chemical business. This packaging manufacturing technology has been certified by UL, a global safety certification organization. The eco-friendly container was applied to all engine oil products under the SK ZIC ZERO and SK ZIC World Series brand. Additionally, the aluminium stopper and the label attached were all unified with polyethene (PE), the same plastic material. If the material is fused in this way, it becomes easier to separate and dispose of the lubricant package after the product is consumed.

4) SK Lubricants manufactured eco-friendly containers from recycled waste plastics by conducting research with SK Innovation’s Chemical Research Center and SK Global Chemical, an affiliate of SK Innovation’s chemical business. This packaging manufacturing technology has been certified by UL, a global safety certification organization. The eco-friendly container was applied to all engine oil products under the SK ZIC ZERO and SK ZIC World Series brand. Additionally, the aluminium stopper and the label attached were all unified with polyethene (PE), the same plastic material. If the material is fused in this way, it becomes easier to separate and dispose of the lubricant package after the product is consumed.

5) Fuchs Lubricants first introduced its Lube Cube in 2012 to tackle the growing environmental concerns. The packaging system was shortlisted as a finalist in the ‘Supply Chain Solution of the Year’ category for the United Kingdom Packaging Awards.

5) Fuchs Lubricants first introduced its Lube Cube in 2012 to tackle the growing environmental concerns. The packaging system was shortlisted as a finalist in the ‘Supply Chain Solution of the Year’ category for the United Kingdom Packaging Awards.

The Lube Cube is fully recyclable and can be included with the normal recycling waste, resulting in significant savings with its disposal. The 20-litre version uses 79% less plastic than a conventional plastic container and cuts disposal costs up to 96%, says Fuchs. Since the launch of this packaging, the company has saved more than 78 metric tons (1.7 million pounds) of plastic, equivalent to 15.6 million plastic bottles or 93.6 million plastic carrier bags.

Nowadays, it’s not just about storing products; it’s about increasing productivity and efficiency as well as reducing cost and harmful impact on the environment. Modern packaging is about keeping these points into consideration. A design is ultimately judged on its usefulness and purpose. Yet with different portfolios and lubricants more specialized, there is a growing focus on creating containers that offer much more.

Consumers and end-users have become more conscious about the importance of a clean environment and greener solutions. Packaging should be easier to clean, recycle and reuse. Studies say that users are ready to pay a premium for more environmentally friendly options. There is a saying that the best things come in small packages, and with the growing demand for flexible packaging in recent times, it appears to be true and believed by the end-users.