Listen to Your Lubricant

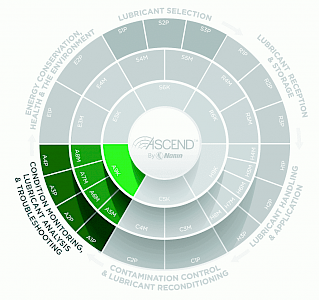

Arguably, more change has occurred related to lubricant analysis and condition monitoring in the past 30 years than all other areas of lubrication. Why does this make sense? The wisest among us know that relentless measurement is a key enabler to forward progress and change. Measurement leads us to awareness and finally to action (tangible results). Of course, there are many other factors that share in importance too. These are thoroughly mapped on the Ascend™ Chart.

Arguably, more change has occurred related to lubricant analysis and condition monitoring in the past 30 years than all other areas of lubrication. Why does this make sense? The wisest among us know that relentless measurement is a key enabler to forward progress and change. Measurement leads us to awareness and finally to action (tangible results). Of course, there are many other factors that share in importance too. These are thoroughly mapped on the Ascend™ Chart.

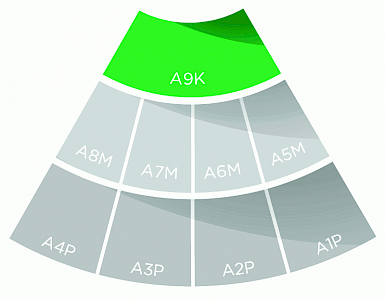

There are nine critical factors in this Condition Monitoring, Lubricant Analysis and Troubleshooting Lifecycle Stage of the Ascend chart. Each one is important enough to justify a feature article describing its purpose and application. And honestly, one or more articles on each of these subjects can already be found at machinerylubrication.com. What has become clear after years of working in the lubricant analysis field is that the concept of best practice is not as intuitive as one would expect at the outset. As a result, from my observation, the vast majority of oil analysis and inspection programs fall miserably short of their full potential.

Therein lies the opportunity and low-hanging fruit ready for harvest. Even those who have benefited from training often seem to struggle with anything more than fragmented execution. We are fully aware that knowing is not the same thing as doing. The Ascend Methodology was devised specifically to enable user organizations to succeed in full and successful execution, each stage, each level, each factor. The roadmap is clear, the journey and execution remain with you.

Listen to your oil… listen to your machine. Lubricant analysis and inspection serve as the most important metric of a lubrication program. I often say, “it’s darn hard for there to be a problem with the machine without the lubricant knowing about it first.” So, let’s examine the oil the right way, again, again and again. The story is being told but we must listen and act.

Platform Level Factors

One of the basic principles of the Optimum Reference State (ORS) is optimization. That’s fundamentally how the ORS is different than from expressions like “best practice” or “precision lubrication.” This means not all machines and not all condition monitoring tasks should be treated the same. Many decisions are driven (or should be) by fundamental concepts derived from criticality analysis and Failure Modes Effects Analysis (FMEA). From real awareness gained from these two analyses, we can move from guessing to decisions made with greater confidence and certainty.

One of the basic principles of the Optimum Reference State (ORS) is optimization. That’s fundamentally how the ORS is different than from expressions like “best practice” or “precision lubrication.” This means not all machines and not all condition monitoring tasks should be treated the same. Many decisions are driven (or should be) by fundamental concepts derived from criticality analysis and Failure Modes Effects Analysis (FMEA). From real awareness gained from these two analyses, we can move from guessing to decisions made with greater confidence and certainty.

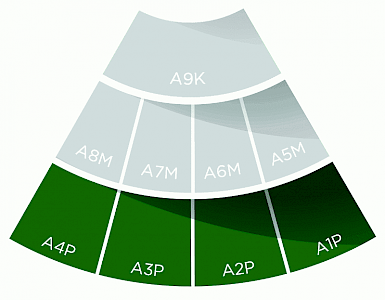

When machines are viewed in the context of criticality and failure modes, the decision of whether to include them in a lubricant analysis program becomes abundantly clear. This is Machinery Selection Factor (A1P) related to inspection tasks, oil analysis, ultrasound and many other condition monitoring activities. There are a number of Lubricant Analysis Data Source options too, such as online monitoring, portable instruments, onsite labs, remote labs and numerous mixtures and variations. This is addressed in Factor A3P.

Once a machine has been included in oil analysis, inspection and condition monitoring program there is a need to know the Lubricant Test Slate for routine and exception samples. This is the objective of Factor A2P. Condition monitoring must be strategic and intentional. This is a bit of an engineering exercise starting with FMEA. Basically, every highly-ranked failure mode needs to have one or most more lubricant tests, inspections and other condition monitoring tasks assigned to it for early detection and remediation. After all, that’s the essence of condition-based maintenance: to detect active failure modes before they become advanced and precipitous failure modes.

Once a machine has been included in oil analysis, inspection and condition monitoring program there is a need to know the Lubricant Test Slate for routine and exception samples. This is the objective of Factor A2P. Condition monitoring must be strategic and intentional. This is a bit of an engineering exercise starting with FMEA. Basically, every highly-ranked failure mode needs to have one or most more lubricant tests, inspections and other condition monitoring tasks assigned to it for early detection and remediation. After all, that’s the essence of condition-based maintenance: to detect active failure modes before they become advanced and precipitous failure modes.

The last Platform level factor in this lifecycle is Sampling Tools and Methods (A4P). To some, this may seem trivial in importance compared to other factors. However, lubricant analysis is constructed from an integrity chain. The strength of the chain is no greater than the strength of the weakest link. So, what is the most common weakest link? It’s the sampling process; where, how, when, what tools, etc. The user organization is totally responsible for this step which is equivalent to laboratory raw material. The finished goods (data) from the oil analysis process can be no better than the quality and timeliness of the sample supplied to the lab.

Management and Training Level Factors

Management and Training Level Factors

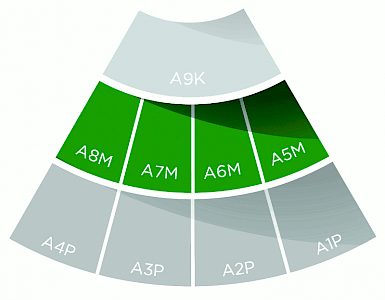

At the Management and Training level there is a need to Select and Integrate Inspection and Condition Monitoring Tasks (A5M). This both unifies and optimizes the condition monitoring program. Data should converge to establish a recognizable and accurate picture of the state of lubricants and machines. Don’t expect that all the data needed can be available from a single bottle of oil. Condition monitoring activities should all work towards a common goal.

Without a doubt, inspection is a powerful and central part of condition monitoring. When well-designed and executed, perhaps 75% of all on-condition work orders are the direct results of motivated, inquisitive and skilful inspectors. To some, the inspection might be viewed as somewhat archaic or pedestrian. But the reality is quite the opposite. Inspections deploy human sensors for which modern technology has no better substitute. Most importantly it leverages the supercomputer in the brain of every human data collector.

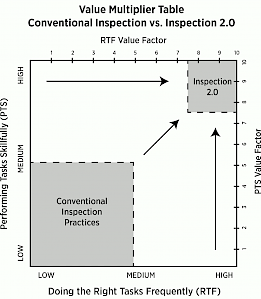

This is the concept of Inspection 2.0 discussed extensively in Noria training courses and on the pages of Machinery Lubrication magazine. It takes the old concepts of inspection and recalibrates them in the context of today’s reliability and condition monitoring culture. It puts emphasis in on examination skills and periodicity. See Figure 1.

You could say that inspection provides the eyes and ears for everything that condition monitoring can’t detect and is a default detection scheme during the intervening days when no technology-based condition monitoring occurs. In other words, inspection fills in critical gaps where there is detection blindness of the technologies and schedule blindness for the time periods between use. Higher inspection frequency and more intense examination skills (by the inspector) significantly increase condition monitoring’s ability to detect root causes and symptoms of various states of failure.

The following are a few core elements related to Inspection 2.0:

The following are a few core elements related to Inspection 2.0:

- Operator-driven. With Inspection 2.0, operators accept serious ownership in machine reliability. This is very similar to Total Productive Maintenance, which stresses the maintenance and reliability is everyone’s responsibility.

- Examination Skills. Condition-based Maintenance (CBM) requires the continuous awareness of the meaningful conditions given off by the machine. It doesn’t care how these conditions become known or understood. Hence, there is a basic need to condition awareness regardless of how this information is discovered, i.e., by inspection or technology-based methods.

- The Power of Frequency. It’s far better to know a fault now by a rather crude means of detection than later with a great degree of accuracy using high technology.

- Root Cause Oriented. A root cause is not a disease but it leads to disease. Once machine wear has occurred we can’t reverse the loss (wear metal for instance). Inspection has the potential to be very proactive and less reactive.

- Fault Bubble Oriented. Contrary to what the name implies, sudden death failures do emit subtle symptoms that if detected could reduce the damage and consequences of failure. This requires inspection frequency for sure but also the ability to detect and respond to the weakest of failure symptoms.

- Lasting Deployment. Inspection 2.0 is culture-driven. Once solidly in place, it has inertia and sustainability.

Data interpretation from condition monitoring can be aided considerably using alarms and limits. When done effectively, the analyst can focus largely on reportable conditions that fall outside of normal ranges. Software and algorithms can help immensely to facilitate the process of Factor A6M, Lubricant Analysis Data Limit Selection and Interpretation. Various alarm techniques can be used to fulfil the requirements of different oil analysis objectives. Although counterintuitive, world-class oil analysis programs seek more alarms and better alarms.

Troubleshooting and Root Cause Analysis (RCA) should also be given due importance and is Ascend Factor A7M. Understanding and learning from both impending failure and postmortem failure is necessary to prevent future failure. Programmatic efforts are needed to instil proper organizational culture among reliability teams to carefully study and document failure. There is no better teacher.

The expression “we earn what we learn” doesn’t just apply to individuals but also organizations and the departmental thrusts within organizations. Education is fundamental to growth and progress. The degree of plant reliability varies in proportion to team education and team culture. Condition Monitoring, Lubricant Analysis and Troubleshooting Training will have a huge impact on program success. This is Ascend Factor A8M.

Key Performance Indicator Level: The Metric of the Metric

Key Performance Indicator Level: The Metric of the Metric

I said previously that lubricant analysis, inspection and condition monitoring together function as an essential metric on the state of machine health and overall machine reliability. This should be used to full potential and value. One way to attain that objective is to also apply metrics or KPIs on how well oil analysis is performing. How can we track its alignment to the Optimum Reference State? There are so many excellent Condition Monitoring, Lubricant Analysis and Troubleshooting KPIs to consider. This is Ascend Factor A9K.