Cracking da Vinci’s Code: Understanding Friction and Friction Modifiers

Tribology is derived from the Greek root “τριβ” meaning “I rub,” which describes the science of rubbing when followed by the Greek suffix “-ology.” Today, this term simply refers to the study of lubrication, friction and wear. Friction should be treated as an enemy when it comes to machine reliability. When friction occurs, the mechanical energy is converted into heat. This heat, when combined with mechanical interactions, leads to wear, vibration and noise. These symptoms should be monitored on a daily basis, as they are the reason why we utilize friction modifier additives in our lubricants. This article dives into the different types of friction along with the role of friction modifiers to help you determine if they are right for your lubrication needs.

Tribology is derived from the Greek root “τριβ” meaning “I rub,” which describes the science of rubbing when followed by the Greek suffix “-ology.” Today, this term simply refers to the study of lubrication, friction and wear. Friction should be treated as an enemy when it comes to machine reliability. When friction occurs, the mechanical energy is converted into heat. This heat, when combined with mechanical interactions, leads to wear, vibration and noise. These symptoms should be monitored on a daily basis, as they are the reason why we utilize friction modifier additives in our lubricants. This article dives into the different types of friction along with the role of friction modifiers to help you determine if they are right for your lubrication needs.

Types Of Friction

Leonardo da Vinci, a tribology pioneer, first discovered the basic laws of sliding friction back in 1493. These are the four types of friction he studied:

1. Sliding

- For example, simply rubbing your palms together is sliding friction.

- In industrial settings, we see sliding friction in Journal Bearings, Slideways, Gates, etc.

2. Rolling

- A heavy ball rolling across the floor will create rolling friction.

- Rolling element bearings, one of the most common mechanical designs, can experience rolling friction.

3. Static

- Pushing up against a heavy desk before it begins to slide is static friction.

- Similar to sliding friction, static friction is the force that holds the object at rest until the force of static friction is overcome and the object starts to move.

4. Fluid

- The resistance felt when stirring a fluid or a boat pushing its way through the water, is called fluid friction or sometimes called “Viscous Resistance.”

- Fluid Friction is a common type of friction often found in industrial machines that require lubrication.

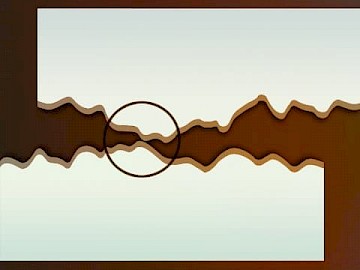

Asperities

Asperities are the rough, microscopic peaks on what is otherwise seemingly smooth surface. Even if the surface has been machined to a mirror finish, it will still have asperities. This is the exact point that friction and wears begin. When the asperities on each surface contact each other, friction is created. This is also the point where fluid friction comes into play in the form of good old lubrication.

In industrial lubrication, we pay a lot of attention to fluid friction, but, believe it or not, we deal with all four types of friction on an almost daily basis. We simply may not see it because it is happening within a component - like ball bearings rolling inside of the race in their housings or sliding friction at the pitch line in the gear teeth of your gearboxes. As friction continues, some asperities become dislodged and tumble in the gaps between surfaces, creating a third body. This gives way to a term known as “three-body abrasion.” This third body represents the aggregate of all particles between the two moving surfaces and with a relative motion of its own.

Friction Factors

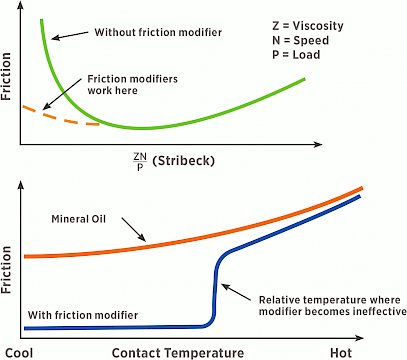

Friction modifiers are mild wear and friction control additives that work at the beginning of mixed-film lubrication. There are many factors that go into deciding to use friction modifiers in addition to extreme pressure (EP) or anti-wear (AW) additives.

Temperature, for example, is a very critical data field to consider when optimizing lubricants. Operational temperature and ambient temperature both affect friction and are very important for specific applications. Two of the biggest factors referenced when selecting the right lubricants are the speed and load of the application. The higher the speed, the more fluid friction. Therefore, the lower your viscosity should be in the lubricant to avoid unnecessary fluid friction. That is one reason why a lot of higher speed pumps and blowers use lubricants with an ISO 46 or 68 Viscosity Grade.

The next big factor that affects friction is load characteristics, including operational load and shock loads. If the load exceeds the recommended capacity of the component, then boundary conditions will result, and friction will occur. Also, the type of relative motion that interacts between the surface asperities plays a role, such as the rolling surface on a ball bearing or the sliding surface on a journal bearing. Lastly, the characteristics of the lubricant (base oil viscosity, base oil type and what additives are in the lubricant) can all affect friction or the coefficient of friction. The challenge when it comes to lubrication is to reduce the friction as much as possible by either eliminating the factors that negatively affect the surface in relative motion or at least attempting to control as many of those factors as possible. The viscosity of the oil is the primary influencer of this, while friction modifiers and other wear and friction control additives help when ideal load, speed and temperature conditions are not met, such as during machine start-ups.

Friction Modifying Additives

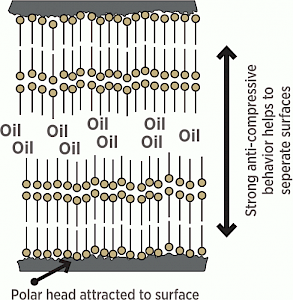

1. Organic Friction Modifiers (OFMs)

- OFMs are amphiphilic surfactants, like fatty acids, often produced as a byproduct of fats and vegetable oils.

- OFMs are common and important additives in engine oils today.

- They adsorb on metal surfaces to form incompressible layers (monolayers) which prevent asperity contact and reduce friction and wear.

2. Oil-Soluble Organomolybdenum Additives

- Originally developed for use as anti-wear (AW) additives.

- Commonly utilized as gear oil.

3. Functionalized Polymers

- Found to adsorb specifically on polar surfaces.

- Shown to significantly reduce wear and friction.

4. (Honorable Mention) Dispersed Nanoparticles

- Honourable mention because it isn’t widely or commonly used in the industrial theatre yet.

- Has been shown to reduce boundary friction, which occurs when a surface is at least partially lubricated, but not so much that there is no direct friction between the two surfaces.

Friction Modifiers

What are friction modifiers? Sometimes called boundary lubrication additives, friction modifiers are additives such as Molybdenum Dithiocarbamate, a common Extreme Pressure (EP) additive, as well as Zinc Dialkyldithiophosphate (ZDDP), a common Anti-Wear (AW) additive. Don’t let the long, goofy words intimidate you - they are commonly referred to as Moly and ZDDP. As a matter of fact, those two perform quite well in conjunction with the same lubricant and increase the efficiency and performance of both the machinery and lubricants.

What are friction modifiers? Sometimes called boundary lubrication additives, friction modifiers are additives such as Molybdenum Dithiocarbamate, a common Extreme Pressure (EP) additive, as well as Zinc Dialkyldithiophosphate (ZDDP), a common Anti-Wear (AW) additive. Don’t let the long, goofy words intimidate you - they are commonly referred to as Moly and ZDDP. As a matter of fact, those two perform quite well in conjunction with the same lubricant and increase the efficiency and performance of both the machinery and lubricants.

Friction Modifiers are additives that also increase the energy efficiency of machines. There are three primary types of friction modifier additives as mentioned in our list: oil-soluble organomolybdenum friction modifiers, organic friction modifiers and functionalized polymers. Functionalized polymers are the most beneficial to elastohydrodynamic and hydrodynamic lubricating films (i.e. moderate rolling and sliding applications). However, the oil-soluble organomolybdenum friction modifiers work best in severe hydrodynamic conditions such as a journal bearing’s heavy sliding contact points. A recent study done by a leading tribology lab lends merit to ZDDP and Moly being among the most common friction-modifying additive packages. The ZDDP has AW or anti-wear properties and is considered a functionalized polymer in relation to the Molybdenum Dithiocarbamate.

What is it about these additives that make them “friction modifiers?" Well, the friction modifiers are kind of like lubrication for lubrication. They create a smooth path for the bulk of the lubricant to flow through the top and bottom surfaces, which is called anti-compressive behaviour, which does exactly what you would expect: it creates the opposite effect of compression by utilizing polarity in the lubricant. Think of it like two magnets' like poles resisting each other, just not as strong. Instead of sucking the surfaces closer together, friction modifiers assist in keeping the surfaces apart. You would be much better off using a good quality, properly formulated and balanced lubricant from the start. One of the first steps in accomplishing this is to make sure the lubricant has the proper viscosity and load-carrying capabilities. Remember, it is better to have your equipment operating with a full fluid film separating its moving parts rather than relying on a friction barrier under boundary conditions. So, in the end, are friction modifiers right for your lubrication needs? You now have the knowledge to help make that decision for your application.

References

- Loren Green “When and How to Use Friction Modifiers”

- How to Reduce Friction between Surfaces

- Friction Nemesis by Bennett Fitch