Keeping Score of Your Lubricant Reception and Storage Process

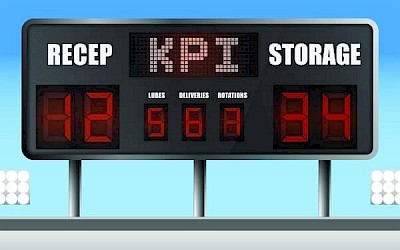

If you have ever invested money in a 401K or the stock market, you might have received a letter in the mail showing your quarterly updates. Personally, I like to skip through all the text and legal script and go straight to a page with a lot of numbers, charts and graphs. These details are important to me as they let me know how certain markets are performing, and they can help predict where things will be in the future. The same thing can be seen if you watch the sports broadcast on the news - they will generally show you the highlights of the game, then throw lots of numbers on the screen such as total rushing yards, total passing yards or how many tackles a player had during the game. These numbers are just like the KPIs (Key Performance Indicators) that we use in the industry. In short, KPIs score how a program is performing and, if plotted out, can show if a program is headed in the right direction. We’re a data-driven society, and if you want to get people’s attention in 2021, show them the facts in numbers.

If you have ever invested money in a 401K or the stock market, you might have received a letter in the mail showing your quarterly updates. Personally, I like to skip through all the text and legal script and go straight to a page with a lot of numbers, charts and graphs. These details are important to me as they let me know how certain markets are performing, and they can help predict where things will be in the future. The same thing can be seen if you watch the sports broadcast on the news - they will generally show you the highlights of the game, then throw lots of numbers on the screen such as total rushing yards, total passing yards or how many tackles a player had during the game. These numbers are just like the KPIs (Key Performance Indicators) that we use in the industry. In short, KPIs score how a program is performing and, if plotted out, can show if a program is headed in the right direction. We’re a data-driven society, and if you want to get people’s attention in 2021, show them the facts in numbers.

Keep Track of KPIs

Whether you are just getting a lube program started or you are striving for a fully-implemented lubrication program, there are many notable KPIs to be tracked regarding lubricant reception and storage. Receiving and storing lubricants is a critical part of the lubricant life cycle, and if certain tasks are not being performed properly (or at all), the entire program could suffer. For instance, if lubricants are routinely delivered to a site without meeting plant cleanliness targets, some remediation with the supplier, or even a supplier change, will be required. If we know oil is delivered dirty and nothing is done about it, these lubricants could slip through the receiving department and end up in a critical machine. Three areas to consider when building lubricant reception KPIs are New Lubricant Deliveries, Lubricant Inventory Rotation and Safety Incidents.

New Lubricant Deliveries

From a lubrication standpoint, one of the best things you can do to maximize machine life is to ensure that you are always using clean lubricants. Some things need to be measured to check the overall effectiveness of the lubricant receiving process. A few of these measurements relate to the cleanliness and dryness of the lubricant. Cleanliness is measured using a particle counter and then reported based on the ISO 4406 standard, which is the reporting standard for fluid cleanliness. We can use this standard to establish cleanliness targets, which can help create a benchmark for how to clean various lubricants need to be for their applications. The same principle is used with dryness targets where the maximum amount of water is reported in parts per million (PPM). An example of this might be that all incoming gearbox oils should have an ISO 4406 Cleanliness Code under 17/14/12 and should have less than 300 PPM of water. The data that needs to be collected for a KPI is the number of lubricants delivered that meet the targets vs. those that do not. If targets are being met on a regular basis, all is well. If they are not meeting targets, a call with the supplier might be in store. A key aspect of this process is sampling incoming lubricants to ensure they are free of contaminants - a step that is often overlooked or neglected. Introducing heavily contaminated lubricants to equipment is an example of a root cause of premature equipment and lubricant failure. Setting a metric around this will help ensure it is tracked.

Lubricant Inventory Rotation

More often than not, as I am doing an assessment I will find at least one outdated lubricant. Lubricants, like many other items, do not last forever. A starting point for setting a lubricant’s shelf-life is to use the information provided by the manufacturer. It is important to remember that when the manufacturer gives suggestions, they assume that the lubricants are being stored in a clean, dry and temperature-controlled environment. Stock rotation systems such as FIFO (First in First Out) ensure that older lubricants are used before more recently delivered lubricants. KPIs can help a program manager know if FIFO and other inventory management systems are working correctly. Making sure that the minimum and maximum amounts of lubricants are being kept in stock is critical. If too many lubricants are being procured and not used, lubricants start to stockpile and can even “spoil” in the lube room. On the other hand, it is an issue if too few lubricants are being stored, and you constantly have to procure on-demand and wait for lubricants to arrive. To track this, you can measure the amount of a particular lubricant that is being stored vs. the amount going into machines every month. If a thousand gallons are being stored and only two hundred gallons are going out every month, the maximum amount held might need to be adjusted. There are a few other variables to consider when determining how much lubricant to store, such as how long it takes the supplier to deliver lubricants or if a high-volume machine needs a change in lubricant during an upcoming shutdown.

Another easy KPI to track over time is the number of lubricants that are rarely or never used. Often, when a new lubricant brand is implemented, the old brand of lubricant is shoved to the back of the lube room. There are different reasons that old lubricants might be kept around; for instance, if a machine is under warranty and is required to use the old lubricant. Another way to achieve an optimized lubricant inventory is with consolidation effort. When there are fewer types of lubricants to manage, they will spend less time in storage. Performing periodic audits of the lube room and stored lubricants should involve taking note of any stock rotation discrepancies for inventory levels. Based on the data, you can then identify areas for improvement.

Safety Incidents

One of the biggest topics in the industry today, and rightfully so, is safety. Many sites have new hire safety training, contractor safety training and occasionally refresher training. With safety being a top priority, KPIs in this area are crucial. Keeping track of accidents and near-misses can help a program see gaps in safety procedures. Injuries are more likely to occur when moving lubricants around the site and can range from back injuries to forklift collisions.

There are also many dangers when performing lubrication activities themselves, such as lubricating running equipment. Equipment can be complex and have many moving components that serve as pinch or nip points. Lubrication equipment can also pose a risk in the form of high-pressure injection injuries. The records for all safety training for lubrication practices given to employees should be readily accessible. If your safety records can segment out lubrication-related safety issues, it provides more insight into these practices rather than just a general safety score.

How does your lubrication program score when it comes to Lubricant Reception and Storage? Are you tracking KPIs to see if your program is moving forward or backward? The key to both is measuring the correct data and putting it into a format that is easy to track from month to month. What Pete Drucker said many years ago is still applicable today: “Only what gets measured gets managed.” If you are striving for a better program, the key to success is in the numbers.