Lube-Tips

How Water Contamination Affects Oil Viscosity

How Water Contamination Affects Oil Viscosity

It’s important to understand what can happen to the viscosity of an industrial lubricant, such as hydraulic or gear oil, when it is contaminated with water. A common misconception is that the water will reduce the viscosity of the lubricant. In fact, if an excessive amount of water is “whipped” into the oil in such a way that it forms a stable emulsion, the viscosity can increase, sometimes dramatically so. The oil/water emulsion will not lubricate as well as clean, dry oil. Not only that, but the viscometric of an emulsion is different than that of oil, so other problems such as poor valve response or high-pressure drops across filters can occur.

Bearing Lubrication Caution

Bearing Lubrication Caution

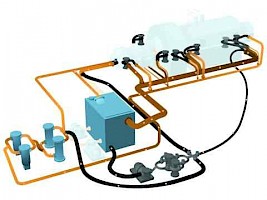

It is important that rolling-element bearings lubricated by an oil circulation system do not rotate at any time in the dry condition, especially after a long period when most of the oil will have drained away from the bearing. Rotation under this condition can cause severe damage to the rolling surfaces. This situation may be avoided by ensuring that the oil pump, which supplies the oil to the bearings, is started before the machine drive system is put into operation

Check Makeup Valves in Oil Sumps

Check Makeup Valves in Oil Sumps

The oil sumps of modern gas engines are getting smaller while the power outputs are increasing. This puts increased stress on the oil in circulation. Many sump levels are controlled automatically by makeup valves. Check the setting of these valves, as they can often be set low, which means you do not get the full charge of oil in the sump and face shorter drain periods. Also, make sure you drain the oil cooler as well as the sump during the oil change, as there is often a considerable amount of old oil (up to 10 per cent) held in the pipework just ready to contaminate your fresh oil.