Oil storage in IBC Containers

Lubrication Program / Lubricant Analysis Sector: Power Generation Topic: Storage of oil in IBC-type containers (1000 litres) and its impact on the availability of generation groups Publish date: December 2021.

Lubrication Program / Lubricant Analysis Sector: Power Generation Topic: Storage of oil in IBC-type containers (1000 litres) and its impact on the availability of generation groups Publish date: December 2021.

The storage of lubricants in 1000 litre deposits is quite common in the vast majority of industrial areas and is the preferred type of storage, especially in power generation plants that have gas or steam Turbines, compressors and turbochargers. The oil in these containers can be stored for a long time until it is necessary to transfer it to the generation system and in many cases, this is where some problems begin.

This article addresses a couple of case studies in order to guide the end-user on the necessary considerations that must be taken into account when working with this type of container and, above all, reveals the impact it has on the availability of the power generation group.

Case 1: Stored oil

| Oil Brand | Oil Type | Batch Date |

|---|---|---|

| A | 1 | 2003 – 2009 |

| A | 2 | 2009 – 2013 |

| B | 1 | 2013 – 2017 |

Perhaps one of the main questions when buying oil in this type of container is, how long does the oil last? Redirecting the question from a more technical aspect, the end user wants to know the time he has to store the oil without changing its properties and functional characteristics. For strictly commercial reasons, the combined cycle (2 gas turbines and one steam turbine) which we will call “CCA” had up to 18,000 litres of ISO VG 32 oil stored in IBC tanks.

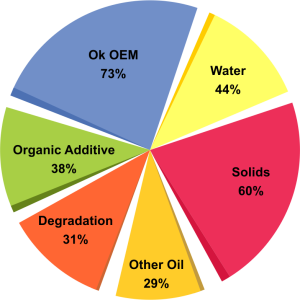

Among the doubts of the plant O&M team was knowing the possibility of putting the stored oils into service. A question formulated in time can avoid many problems, as we will see in the following case. With the help of a manual pump, a sample was taken as close as possible to the central part of each tank and the results of the oil analysis were decisive in knowing its status. The following graph shows the percentage of IBCs with oils above the acceptable limits of water and solid contamination, as well as those samples with clear evidence of loss of organic additive (the one that slows down the effect of oxidation in these formulations) and signs of degradation of the base oil.

| Loss of Organic Additive | 14% |

|---|---|

| Base Oil Degradation | 16% |

| Water Contamination | 32% |

| Solid Contamination | 38% |

Based on this first analysis, it is evident that the commissioning of oils that have a level of degradation and/or those that have organic additives below acceptable levels does not make sense and could affect the performance of the oil in the short term later the availability of the turbine. Therefore, the CCA disposed of 8 of the 18 IBCs of turbine oil.

A connector with two outputs was installed in the upper part of the 10 units that remained on the site, one of them for a desiccant filter and the other for a quick connector; while in the lower part of the IBC a quick connector was installed to facilitate the filtration and subsequent removal of contaminants.

Thanks to a previous compatibility analysis between the oils, single filtration equipment was put into operation that is used periodically to keep the conditions of the oils under control, in addition, semi-annual oil analysis is carried out on each IBC in the plant.

The question that arises after reading this case is to know if there is any relationship between the date of manufacture of the oil and the loss of chemical properties (degradation and organic additives). At least, in this case, there is no relationship between the age of the oil and the mentioned parameters. As a side note, the purchasing department plans to continue purchasing at least 2,000 litres per year of turbine oil.

Case 2: Commissioning and group trip

Turbine OEMs are quite clear about commissioning their equipment, either at the start of operation or after a maintenance shutdown. The manufacturer's manuals include a lot of information regarding the conditions of the oil, the recommended tests as well as the applicable regulations and the limits that the results of the oil analysis must meet.

Turbine OEMs are quite clear about commissioning their equipment, either at the start of operation or after a maintenance shutdown. The manufacturer's manuals include a lot of information regarding the conditions of the oil, the recommended tests as well as the applicable regulations and the limits that the results of the oil analysis must meet.

Based on all this information and often with the support of an oil analysis laboratory, the end user must make the decision to put the oil into service or not.

In 2014 the CT generation plant was ready to start up the new group only in the absence of the results of the oil analysis. A little back in time, the 6000 litres of ISO VG 46 oil arrived at the plant around 8 months before the group started up and the oil analyzes carried out at that time did not show any problem with the oil, at least from the point of view of the laboratory in charge of the analyses.

A second oil analysis carried out a couple of weeks before the unit was started revealed that the vast majority of results were within OEM-approved parameters. It was decided to start the group and after 30 hours the temperature of the oil increased by 4 0 and reached 7 0 after 45 hours.

For safety reasons it was decided to shut down the group and send another sample to the laboratory, the parameters were very similar to the sample before start-up, the site changed the filters and after a visual inspection, they gave the green light for the group to start working again. Once again, after a short period of time, the temperature exceeded 7 0 and it was decided to permanently shut down the group.

As mentioned in the previous case, in some cases turbine oil that has been stored for a while tends to degrade. Now, measuring the degradation is very easy for a laboratory with experience in the area of power generation, but the alarms can be missed in those cases where the end-user chose to work with a laboratory that lacks resources and knowledge.

As my friend Luis Garcia from TBN Canarias says, "when the rook flies low..." referring to the fact that when something is wrong, it is very obvious, at least for those who know how to read it.

| Test OEM | New Oil | In Service Oil |

|---|---|---|

| Viscosity@40 | 46 | 46 |

| Metals | OK | P: +10ppm |

| TAN | 0.14 | 0.16 |

| Particle Count | 16/14/9 | 17/14/10 |

| Water KF | 49 | 42 |

| Varnish | 3 | 12 |

| Degradation | Yes | Yes |

The explanation, in this case, is relatively simple. The degraded oil base slightly lost one of its functional properties, minimizing the foam effect (please don't look for Silicon!). There is clear evidence of this in oil analysis that was overlooked. Once this oil is put into operation, the normal operating temperature is responsible for enhancing the problem and the trapped air bubbles, due to the poor antifoam effect, implode in the high-pressure areas (an effect known as micro dieseling) this generates increases in temperature in the system, degradation by-products are generated and some of them agglomerate and transform into semi-solids, known as lacquers or varnishes.

Unfortunately, the CT plant had to postpone the startup of the group for 3 months, it also had to dispose of all the oil, change the filters and perform a deep cleaning of the system.

The economic impact of the previous points is incipient compared to the economic loss due to not having produced energy within the established period. Returning to the beginning of the article, the storage of oils, at least turbine oils, in IBC-type containers requires special attention and the analysis should be carried out by a laboratory with sufficient knowledge to detect problems in advance.

Case 3: Some IBCs under the microscope

The two previous cases denote the importance of making decisions based on oil analysis. But how many generations of plants really take the necessary measures to minimize these problems? How many maintenance teams are aware of these potential problems?

The two previous cases denote the importance of making decisions based on oil analysis. But how many generations of plants really take the necessary measures to minimize these problems? How many maintenance teams are aware of these potential problems?

These are questions that will remain up in the air, meanwhile, let's see a much more extensive study on the conditions of turbine oil that I have been carrying out for more than a decade and in more than 8 countries.

The results of the analysis are overwhelming. If we read them carefully and understand how they can affect the performance and availability of a power generation group, we would understand how critical it is to have the right oil analysis at the right time. Logically, contamination with solids and water is one of the factors that attract the most attention and is probably the easiest to treat due to its characteristics.

On the other side of the coin, we have other types of problems whose only solution is probably to dispose of the oil and not put it into service.

29% of the samples show signs of being contaminated with another type of oil or fluid! This coincides with plants where an oil tanker transfers a volume into containers that are in use at the plant. This type of contamination is irreversible and depends on the conditions the oil can be used or not.

We have already seen what can happen when oil shows signs of degradation and the chaos it can cause to the operation. Similarly, the organic additive plays an important role in certain types of oils and requires regular analysis and control.

Some recommendations, they can save the day!

Does your plant store oil in IBC containers? Treat them with more care, deposit them under a roof and four walls, and verify that when breathing (expansion and contraction of the material) the air that enters the interior of the IBC is clean and as dry as possible. If they are too translucent, in other words, if you can see the colour of the oil through the container wall, cover them with a dark sheet to avoid the effect of UV radiation. If the sheet is waterproof and antistatic, you got a 10! This is one of the main causes of all headaches in these types of oils. Do regular oil analysis and do it with a lab with experience in the area of power generation and if the lab has a reliability engineer on staff, you've hit the nail.

Do not take a dim view of the price of the analysis. No! You are not wasting money, you are investing in the protection of the generating group. If possible, include this analysis in your Industry 4.0 project budget, just at the bottom where no one can see it (this has nothing to do with AI or ML… sorry)

If possible, coordinate with your purchasing department the acquisition when necessary, at the same time coordinate with your oil supplier the response time in case of an emergency and, if possible, avoid storing the product for a long period of time.