Requirements of Heavy-Duty Diesel Engine Oils

1. What Drives the Changes in Diesel Engine Oil Specifications?

The main drivers for recent changes in engine oil formulation and specifications have come from three sources: the government, original equipment manufacturers (OEMs), and the consumer.

2. Engine Oil Requirements

2.1 What Engine Oil Must Do?

Engine oil reduces friction and prevents wear between the moving parts of the engine. The development of more powerful engines is constantly changing the technology of engine oils formulated for use in today’s modern engines. The efficient operation of any engine depends on the engine oil performing many functions.

2.2 Permit Easy Starting, and Pumping

The ability of an engine to reach a critical firing speed promptly, and keep running depends not only on the condition of the battery, starter, and ignition system, proper fuel volatility, and air/fuel ratio but also on the flow properties of the engine oil. The viscosity of the engine oil in engine journal bearings during cold temperature start-up is the key to determining the lowest temperature at which an engine will start. The Cold Cranking Simulator Viscosity (ASTM D-5293) is determined under conditions similar to those experienced in engine bearings during start-up from -10°C to -35°C and under high shear rate conditions. All oils thicken when the temperature drops, but there is also a danger that wax and additive components of the engine oil may come out of the solution at low temperatures, and convert the engine oil to a gel-like thick milkshake or even a solid (ASTM D-4684).

2.3 Lubricate, and Prevent Wear

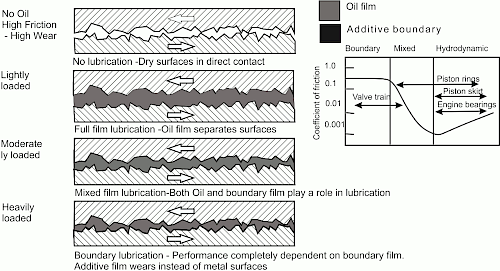

Once an engine is started, and pumping of the engine oil begins, it quickly circulates to all moving parts of the engine to prevent metal-to-metal contact that would result in wear, scoring, or seizure of engine parts. Oil films in bearings and on cylinder walls are sensitive to movement, pressure, and oil supply. The viscosity of engine oil must be low enough at starting temperatures to permit rapid cranking and starting, and high enough at peak operating temperatures to ensure adequate engine protection. Unless counteracted by the oil’s anti-wear additive system, the result is either immediate seizure or the tearing apart, and roughening of the surfaces when the film is not developed. Such conditions are found around the top piston ring where oil supply is limited, temperatures are high, and a reversal of piston motion occurs, Fig. 1 . Full film lubrication occurs when a film of oil continuously separates the moving surfaces.

2.4 Reduce Friction

The viscosity of the engine oil should be high enough to maintain an unbroken film, but should not be higher than necessary, since this increases the amount of force required to overcome this fluid friction, reducing engine fuel economy. The viscosity increases as the oil become contaminated with soot, dirt, and sludge, and decreases if it is contaminated with fuel.

2.5 Protect against Rust and Corrosion

For a variety of reasons, an engine does not burn all of the fuel completely. Te other by-products from in-complete combustion of the fuel like nitrogen oxides, and sulfur oxides dissolve into the engine oil apart from the acids formed by the normal oxidation of oil, and hence the potential for rust and corrosion is significant.

2.6 Keep Engine Parts Clean

Combinations of water from condensation, dirt, the products of oil deterioration, and the by-products of incomplete combustion of the fuel become sludge deposits at low engine operating temperatures. Therefore, a basic objective formulation of engine oils is to keep the engine clean and prevent the build-up of sludge, and varnish deposits from interfering with proper engine operation. In performing its lubrication function, some oil must reach the area of the top piston ring to lubricate the rings and cylinder walls. To further control combustion chamber deposits the engine oil is formulated from base oils that exhibit low volatility characteristics as it comes in contact with the turbocharger, cylinder walls, valves, and the under-crown, and ring belt area of the pistons.

2.7 Cool Engine Parts

After the warm-up, engine oil temperatures reach 93° to 135°C, and the oil is supplied to the bearings at this temperature. What is critical is the continuous circulation of large volumes of oil throughout the engine, and over hot engine parts. This is made possible through the use of an oil of the right viscosity for that engine, high-volume oil pumps, and unclogged oil passages adequate to handle the required volume of oil.

2.8 Seal Combustion Pressures

The surfaces of the piston rings, ring grooves, and cylinder walls show minute asperities. Engine oil fills these and helps to seal the combustion chamber. Oil consumption may also be high in a new or rebuilt engine until the hills, and valleys on these surfaces have smoothed out enough to allow the oil to form a tight seal.

2.9 Non-foaming

Because of the many rapidly moving parts in an engine, the air in the crankcase is constantly being beaten into the engine oil. To help ensure proper engine protection, all engine oils contain anti-foam additives.

2.10 Aid Fuel Economy

Engine oils are formulated to provide fuel economy benefits. There are two ways engine oils may help to improve fuel economy. For both monograde and multigrade engine oils, friction reduction is achieved by the use of additives (surface-active materials) that lower the friction during boundary lubrication, which do not interfere with anti-wear/extreme pressure agents. Tis can also be accomplished by changing to lower viscosity oil, causing less friction. Also, multigrade oils that contain polymeric additives as viscosity index improvers, provide a variable viscosity when lubricating high shear zones. This results in reduced resistance to flow, lower operating temperatures, and better fuel economy.

3. Components of Engine Oil Performance

3.1 Viscosity

The viscosity of the oil is the resistance to flow and is a basic criterion for predicting engine oil performance. To ensure that the proper viscosity grade is used the Society of Automotive Engineers (SAE) has developed a viscosity grade classification for engine oils. The worldwide standard for defining engine oil viscosity is the SAE viscosity classification system assigning a grade to a specific viscosity range; the high-temperature, high shear (HTHS) viscosity relates to the viscosity at 150°C under shear stress conditions similar to the very thin film area found at the piston ring to-cylinder wall interface. These oils (SAE 5W-40, 10W-30, SAE 15W-40, or other combinations) can be used over a wider temperature range than single-grade oils. A higher viscosity index shows less change in viscosity over a wide temperature range. For example, an SAE 10W-30 engine oil meets the Cold Cranking Viscosity, and Mini-Rotary Viscosity low-temperature viscosity requirements of SAE 10W, and the high-temperature viscosity requirements of SAE 30.

3.2 Protection against Wear, Deposits, and Oil Deterioration

Deposits like sludge, and varnish cause valve and ring sticking, clogged oil passages, piston, and cylinder wear. Oil deterioration – the result of high-temperature oxidation, and reaction with combustion by-products can increase the viscosity of oil, and impede oil flow to critical engine parts.

4. How Engine Oil Performance

Standards are developed Several guidelines have been developed to define the overall capability for gasoline, and diesel engine oils to prevent wear, deposit formation, and oil deterioration by the following institutions: (1) Te American Petroleum Institute (API) in conjunction with the SAE, the American Standard for Testing Materials (ASTM), ILSAC (International Lubricant Standardization and Approval Committee), and the Diesel Engine Oil Advisory Panel (DEOAP), (2) ILSAC is composed of North American and many Japanese automobile manufacturers, (3) Individual OEMs. The development of any new diesel API Service Classification is done in three phases that consist of three following steps for a category: Request, and Evaluation, Development and Implementation

4.1 API Licensing Process

If the candidate oil qualifies, the oil marketer must enter into a formal licensing g agreement to display the API Certification Mark (Starburst), and/or API Service (Donut) on their oil containers.

4.2 API Current Service Classifications, 2021

| Category | Service |

|---|---|

| CK-4 | API Service Category CK-4 describes oils for use in high-speed four-stroke cycle diesel engines designed to meet the US 2017 model year on-highway and Tier 4 non-road exhaust emission standards as well as for previous model year diesel engines. API CK-4 oils are designed to provide enhanced protection against oil oxidation, viscosity loss due to shear, and oil aeration as well as protection against catalyst poisoning, particulate flter blocking, engine wear, piston deposits, degradation of low- and high-temperature properties, and soot-related viscosity increase. |

| CJ-4 | For high-speed four-stroke cycle diesel engines designed to meet the US 2010 model year on-highway and Tier 4 non-road exhaust emission standards as well as for previous model year diesel engines. API CJ-4 oils exceed the performance criteria of API CI-4 with |

| CI-4 | PLUS, CI-4, CH-4, CG-4, and CF-4 can effectively lubricate engines calling for those API Service Categories |

| CI-4 | CI-4 oils are formulated to sustain engine durability where exhaust gas recirculation (EGR) is used and are intended for use with diesel fuels ranging in sulfur content up to 0.5% by weight. |

| CH-4 | CH-4 oils are specifically compounded for use with diesel fuels ranging in sulfur content up to 0.5% weight. |

| FA-4 | API Service Category FA-4 describes certain XW-30 oils specifically formulated for use in select high-speed four-stroke cycle diesel engines designed to meet 2017 model year on-highway greenhouse gas (GHG) emission standards. API FA-4 oils are designed to provide enhanced protection against oil oxidation, viscosity loss due to shear, and oil aeration as well as protection against catalyst poisoning, particulate flter blocking, engine wear, piston deposits, degradation of low- and high-temperature properties, and soot-related viscosity increase. |

4.3 ACEA Specifications

Oil can be approved against many different specifications that are issued by industry bodies such as ACEA (Association des Constructeurs Européens de L’Automobile), the API, or individual vehicle manufacturers. For heavy-duty diesel engine oils, the ACEA specifications are referred to as “E” Sequences: Sulfated ash content, % Sulfur, % Phosphorus, % Noack Volatility, High-Temperature High Shear Viscosity, TBN

4.4 OEM Specifications

Some OEMs like Caterpillar, Cummins, Detroit Diesel, Mack, and Volvo create and recommend their engine oil performance standards when a need or a desired performance level is not met by a current API Service Classification.

4.5 Why Have Some API Service Classifications Become Obsolete?

For the diesel engine oil service categories, new categories cannot always include the performance properties of all of the prior categories.

5. Engine Oil Composition

Heavy-duty diesel engine oils are comprised of approximately 75 to 85% base oil with the remainder made up of additive systems.

5.1 Base Oils

Te base oils used in the formulation make up a substantial portion of the finished lubricant and contribute significantly to the performance characteristics of the finished oil in areas such as thermal stability, viscosity, volatility, the ability to dissolve additives, and contaminants (oil degradation materials, combustion by-products, etc.), low-temperature properties, air release/foam resistance, and oxidation stability. Base oil is defined as a refined petroleum fraction or a synthetic material that is produced to a given set of specifications by a single manufacturer. Mineral-based oils are derived from petroleum base oils. Petroleum-based oils are derived from crude oil, which is also used to produce gasoline, diesel fuel, kerosene, asphalt, gases, and petrochemical feed-stocks. Of these types of crudes, the most favoured type of crude used for producing petroleum base oils are the paraffinic type crudes, which are analogous to long straight kinds of pasta such as spaghetti, because of their high viscosity index. Unconventional base stock refining utilizes severe hydrocracking refining techniques such as two-stage hydrotreating process, hydroisomerization, or iso-dewaxing/hydrocracking processes. During the refining process the different types of hydrocarbons are separated into different types through the process of distillation (kind of like removing the very big, and little pieces of pasta), cracking (like breaking the very long pieces of pasta like linguini, and spaghetti into shorter pieces), hydrogenation (converting some pieces into others), and dewaxing (removing certain large pieces like lasagna), and so forth. These processes produce approximately two-thirds of the world’s paraffinic base stocks.

The two basic processes used for obtaining petroleum lubricant base stocks consist of separation and conversion processes are as follows. [1] Separation type procedures: (a) distillation: atmospheric, vacuum, (b) propane deasphalting, (c) solvent extraction (d) solvent dewaxing. [2] Chemical conversion procedures: (a) hydrotreating, (b) hydro finishing, (c) hydrocracking methods like two-stage hydrocracking, raffinate hydroconversion, isodewaxing/ hydroisomerization, (d) catalytic dewaxing. To further improve the performance of the lubricant base stock performance several hydro-processing techniques can be used. These hydroprocessing methods use hydrogen in the presence of a catalyst to further remove impurities and improve performance: hydro finishing (hydrotreating), hydrocracking, hydroisomerization.

5.2 Synthetic Base Oils

Synthetic base oils are base stocks in which a chemical conversion of one complex mixture of molecules into another complex mixture has taken place. They have higher viscosity indexes, flashpoints, lower coefficients of traction, (lubricant's molecular resistance to motion of one layer of fluid sliding over or along with another layer of fluid), and lower pour points than mineral base stocks.

5.3 API Base Oil Categories

Base oils used in the formulation of engine oils with different physical and performance properties depending upon their crude source, refining methods, and the chemical conversion methods used to produce them are divided into five API categories, Table-1.

| Group | Sulfur, % weight | Saturates | V.I. | |

|---|---|---|---|---|

| I | >0.03 | and/or | ≤ 90 | 80-120 |

| II | ≤ 0.03 | and | ≥ 90 | 80-120 |

| III | ≤ 0.03 | and | ≥ 90 | ≥ 120 |

| IV | All PAO | |||

| V | All base oils not included in Groups I-IV (naphthenic, esters, and polyglycols) | |||

Note: In recent years, these categories have been informally subdivided into Group I+, Group II+, and Group III+

Groups I, II, III are classified by the amounts of saturates, and sulfur content, and by the viscosity index of each. Group V is reserved for other base stocks such as diesters, polyol esters, polyalkylene glycols, naphthenic, and aromatic stocks.

detergents

5.4 Detergent-Dispersant Additives

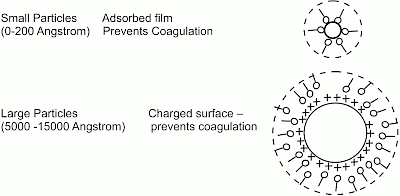

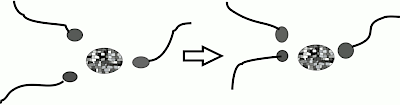

Oils deteriorate due to oxidation or contamination and form insoluble sludge and varnishes and resins on the surfaces of the engine and can block oil passages. Tey lifts any deposits from the engine surfaces to form a barrier film, which keeps the deposits from coming out of suspension and coagulating, Fig. 2 . These molecules attract each other like magnets and form clusters called “micelles”. The oil-insoluble precursors of deposits have a greater affinity for the detergent molecule than the oil molecules. When the number of particles exceeds the capacity of the type of detergent, then deposits can form. Also, detergents neutralize any acids formed by the combustion by reacting to form harmless neutralized chemicals.

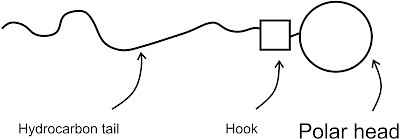

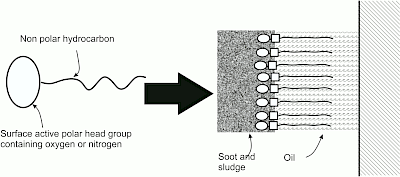

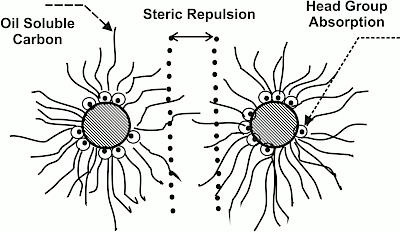

Polar dispersants (Fig. 3) envelop soot particles and scatter sludge and soot particles preventing agglomeration and settling. The polar heads attach themselves to deposits or deposit precursors or acids that may be formed by the combustion of the fuel to form micelles. Dispersants can hinder the agglomeration of soot, sludge, and dirt particles via two different mechanisms, Fig. 4 . (1) Steric stabilization: once the polar head group has adsorbed onto the surface of the dirt particle, the tail provides a physical barrier to attraction, Fig. 5 9. (2) Electrostatic stabilization: Dispersants can also induce a charge on the soot, sludge, and dirt particles. Agglomeration is then inhibited by electrostatic repulsion of the negatively charged dirt particles, Fig. 6 10.

particle providing a physical barrier to

attraction

5.5 TBN

As previously stated earlier in this discussion on detergents and dispersants, one of their functions is to help neutralize any acids that are formed by the combustion of the fuel, by proving the engine oil with a Total Base Number (TBN). The oil must have the ability to retain its alkalinity reserve contributed by both the detergents and dispersants during its entire drain interval, the former offering the best alkalinity reserve, over the entire drain period.

prevention from coming into contact with

others and increasing in size

5.6 Anti-Wear Additives

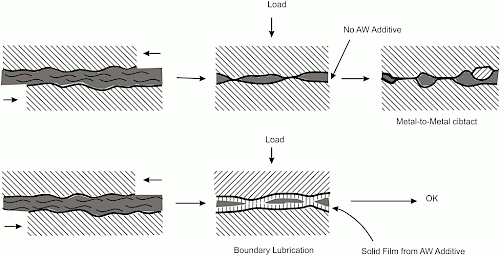

During periods of high shock loading, high pressures, high speeds, heavy loading, or at cold start-up, the lubricant film between the two metal surfaces is either squeezed out or ruptured, causing the two metal surfaces to come into contact with each other and as a result, the entire load is carried by the contacting metal surfaces, Fig. 7. The predominant type of antiwear additive for the past 50 years is zinc diorgano dithiophosphate (ZDDP), Fig. They dissolve all of the inorganic compounds in the molecule (such as zinc) in oil so that they can be carried by the oil to where it is needed. ZDDP breaks up at high temperatures to form protective films of zinc sulfides and zinc phosphates.

particles

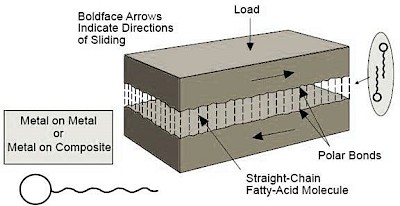

5.7 Friction Modifier

They reduce the coefficient of friction and prevent wear where boundary lubrication conditions occur like the piston rings and the cylinder walls at dead centre reversal points or the valve train. They work by plating and absorbing on the metal surfaces of the engine to form a long-lasting solid lubricant film, Fig. 8.

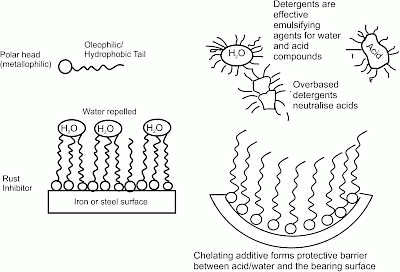

5.8 Rust and Corrosion Inhibitors

Corrosion particularly of ferrous metal surfaces occurs when oxygen and moisture act together on the metal surfaces, further aggravated by the presence of acids formed by the oxidation of the oil or the combustion of the fuel, Fig. 9.

5.9 Oxidation Inhibitors

adsorbed to the metal surfaces to form a

long-lasting solid lubricant film

At high engine operating temperatures, and in the presence of catalytic metals like copper and its alloys, the oxygen in the air reacts with the oil to form unstable compounds known as free radicals and peroxides. If allowed to go unchecked, it can lead to corrosive bearing wear, abrasive wear of various parts of the engine, plugged filters, and oil passages, lack of lubrication, and eventual engine failure. Therefore, oxidation inhibitors are added to extend the life of an engine oil 10 to 100 times.

5.10 Viscosity Index Improvers

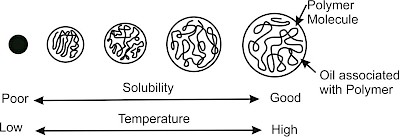

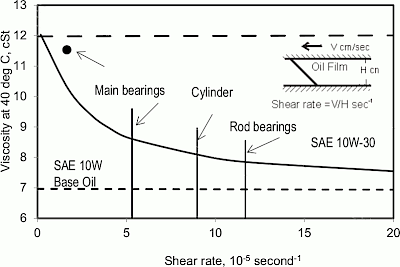

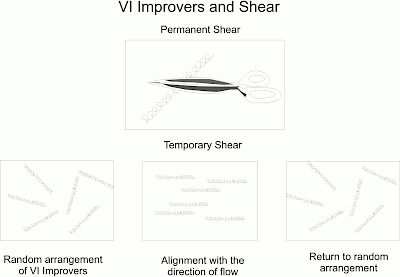

The ideal engine oil would have a constant viscosity adequate to prevent contact of the contacting metal surfaces of the engines at high temperatures while reducing viscous drag at low temperatures. In other words, at low temperatures, the thickening in viscosity is less than that at higher temperatures, because at low temperatures the viscosity index improver is less solvated, occupies a smaller volume, and tends to contract and be attracted to itself than to the molecules of the base oil by folding upon itself to form small coils or clumps of the polymer that interfere less with the flow of oil and offer less resistance to oil flow and pumpability, Fig. 10 However, the use of VI improvers can lead to problems if they do not exhibit shear stability (resistance to mechanical shear or tearing apart of the polymer structure), and chemical, and thermal stability. Unlike monograde oils, multigrade oils exhibit non-Newtonian viscoelastic rheological characteristics, i.e., their viscosity depends upon the degree of mechanical shear stresses, Fig. 11. When the engine oil leaves the high shear zone, the polymers revert to their former arrangement, and the engine oil recovers its higher viscosity.

High shear rates can also cause a permanent loss in viscosity due to the breakdown of the polymer to lower molecular weight fragments, Fig. 12 In addition, polymers can also lose viscosity by undergoing thermal degradation can occur when they break down by chain scission or oxidative degradation when weak carbon to hydrogen bonds react with oxygen to form hydroperoxides and peroxide radicals. Loss in viscous grip can result in increased: oil consumption, oil leakage, engine noise, deposits on critical engine parts, fuel consumption, wear, and emissions. Therefore the right type of chemistry must be chosen to provide not only shear stability but also improved viscosity-temperature characteristics, particularly low-temperature viscosity, and protection against the formation of high-temperature deposits.

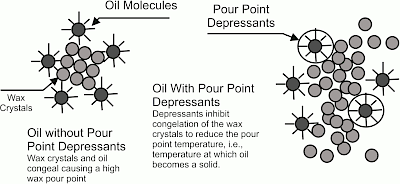

5.11 Pour Point Depressants

The pour point is the lowest temperature at which the lubricating oil will pour when cooled under defined test conditions. At low temperatures, these kinds of paraffin tend to separate as crystals and form a lattice honeycomb-like structure that can trap a substantial amount of oil via association, thus inhibiting proper oil flow and circulation to critical engine parts at start-up leading to catastrophic wear. Base oil refiners remove most of the wax through the use of either solvent dewaxing or catalytic dewaxing processes. To control problems with the crystallization pour point depressants are used, e.g., high molecular weight organic polymers that are either alkylated naphthalenes, oligomerized alkylphenols, polyalkylmerthacrylates, ethylene-vinyl acetate copolymers, or phthalic acid esters, Fig. 13.

temporary shear

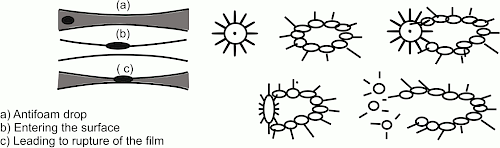

5.12 Foam Inhibitors

Air can be whipped into the oil by the rapidly moving of the engine, or be trapped in the oil during high-pressure release or when the oil pump sucks in air with the engine oil resulting in a mass of oily foam. This compressible foam impairs its ability to prevent wear and can result in the collapse of hydraulic valve-lifters. Surface-active foam-inhibitor chemicals in a few ppm (polymeric materials: polysiloxanes, polydimethylsiloxane i.e., silicones or poly alkyl acrylates) attach themselves to the air bubbles formed by the whipping of the oil. They form unstable bridges between the bubbles, alter the surface tension of the oil, and facilitate the separation of air bubbles from the oil phase, Fig. 14.

6. Maintaining and Changing Engine oils

Only fully formulated and fortified engine oils can provide the protection required by modern, high precision heavy-duty diesel engines. The most important thing about additives is that no matter what their chemical make-up is the amounts they are used in the formulation, and the types of base oils, they are only effective for a certain period.

6.1 Oil Change Intervals

Engine oil drain intervals are governed by the “severity” of use, and by the amount, and types of contaminants to which the engine is exposed. The detergent/ dispersant, anti-wear, oxidation inhibitors, rust, and corrosion inhibitors eventually become depleted, and the oil eventually loses its ability to prevent the formation of deposits on or the wear of critical engine parts. For this reason, it is essential to drain the oil before contaminant levels, and other stresses on the oil exceed the engine oil’s ability to handle them. The best guide to proper oil drain intervals in a heavy-duty diesel engine is the recommendations published by the engine manufacturer.

6.2 Used Engine Oil Analysis

A scientific and regular analysis of used engine oil ensures that the engine oil is performing. A historic data-base and trend analysis of the following are maintained: (a) The condition of the engine oil, and if it is still serviceable or ready for change, (b) Te presence of contaminants such as dirt, water, soot, or process contamination, (c) Te presence of wear to identify the possibility of failure or to assist in making critical maintenance decisions

A scientific and regular analysis of used engine oil ensures that the engine oil is performing. A historic data-base and trend analysis of the following are maintained: (a) The condition of the engine oil, and if it is still serviceable or ready for change, (b) Te presence of contaminants such as dirt, water, soot, or process contamination, (c) Te presence of wear to identify the possibility of failure or to assist in making critical maintenance decisions

Used oil samples can tell if water, coolant, or fuel is mixing with the engine oil, indicating a head gasket leak or a leaking fuel injector can forewarn impending problems. Te good oil analysis report will provide information regarding: (a) If the unit can go to the next maintenance or sampling interval without any issues, (b) If there is a problem what is it? (c) If any excessive wear or contamination takes place. (d) Is the lubricant suitable for continued use? (e) If engine oil-drain intervals are extended? (f) Any wear trends that may be occurring? (g) What corrective actions may or need to be taken?