Best Practices to Control Varnish in High-Volume Oil-Circulating Systems

In the context of lubricating and hydraulic systems, the term “varnish” is used to refer to gel- or resin-like or solid varnish-like deposits that form in fluid systems.

In the context of lubricating and hydraulic systems, the term “varnish” is used to refer to gel- or resin-like or solid varnish-like deposits that form in fluid systems.

Varnish causes:

- Elevated turbine bearing temperature due to increased friction in the bearing

- Functional problems with the control valve due to increased deposits in the gap between the piston and the housing

- Cooling problems due to the varnish impeding heat transfer

- Short filter lifetimes

The cause of these lacquer-like varnish deposits is oil ageing and becoming damaged at the molecular level.

In most cases, however, the above malfunctions are not correctly attributed to the real cause. This results in ineffective (and often very expensive) repair work.

Causes of the Increase in Varnish Formation

Today, system operators are confronted with the fact that the base oils used are changing or have already been changed. While in the past, an oil was produced exclusively in crude oil distillation (Group I oils), modern processes are used to reduce the content of substances hazardous to health (e.g., aromatics). The change in the oil production process has resulted in base oils with a lower content of unsaturated/polar hydrocarbons (Groups II, II+, and III). With Group 1 base oils being polar, polar substances were more easily dissolved. The changes in oil production have led to an oil with less polarity; therefore, a reduction of the amount of polar substances that can be dissolved in the oil is now being seen in hydraulic oil systems. Varnish is an incredibly polar substance that is no longer easily dissolved in the newer base stocks.

Polar substances tend to dissolve more readily in polar substances. If the proportion of polar hydrocarbons in the oil is reduced, oil ageing products (more commonly referred to as “varnish”) cannot dissolve as easily. The effect is oil turbidity or deposits in the system. These changes usually start once the oil has been in operation for 3 to 4 years. As soon as the solubility limit for varnish is exceeded, it precipitates and forms conglomerates, which lead to deposits in the system. Varnish is not heavier than oil and deposits on metal surfaces and at colder locations (tank, cooler, valve body) in the system - not on the tank bottom!

Due to the low proportion of polar substances, these oils also have low electrical conductivity. If this oil flows through the filters in the hydraulic system, an electrostatic charge can be generated. Electrostatic discharge (ESD) occurs in turbine lubrication systems as a result of friction between the fluid and the system components. An indication of ESD is a clearly audible clicking sound as the accumulated charge discharges, causing sparking internally within the system.

Less apparent effects involve movement of the electrical charge downstream of the filter, which produces damage to system components and the filter.

The amount of charge generated by the flow of oil through a filter is related to several fluid and filter properties. The charge generation/accumulation generally increases with increasing flow rates (velocity through the filter element). Reduced fluid conductivity, certain additive packages and lower temperature (higher oil viscosity) can also lead to increased electrostatic charge in the oil.

The subject of oil ageing is not new by any means; in fact, it has always been an issue. The characteristics of oils have changed due to the introduction of more highly refined base oils. The hydraulic oils are expected to handle higher temperatures, be more efficient and have reduced levels of hazardous components.

This means that fluid monitoring and fluid conditioning are becoming more and more important.

Today’s technical data sheets for oils do not give information on the base oil used. Since oil names are often not changed when the oil type is changed, it may mean the old oils are inadvertently mixed with new, more modern oils during refilling. Such mixing can result in chemical reactions, which, under certain circumstances, may lead to the precipitation of reaction products and to deposits within the system.

How Do I Recognize Varnish?

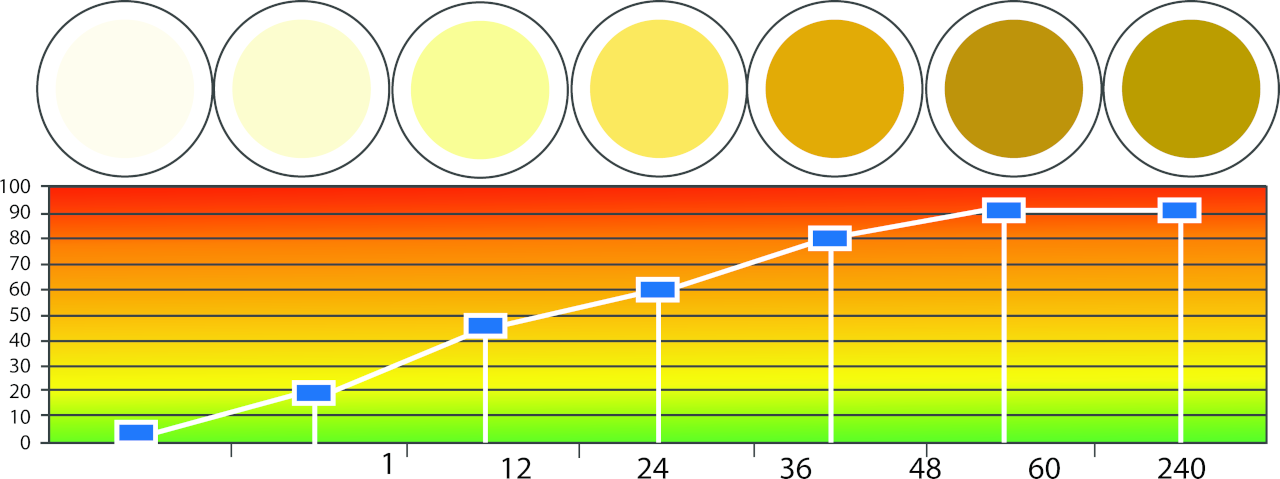

The presence of varnish in oil cannot be detected through routine lab analysis. In laboratory reports, the varnish is found as a dark precipitate on a filter membrane. This testing is called an MPC (Membrane Patch Colorimetry) which records the changes in the colour of a filter membrane with a 0.45µm filtration rating. Critical system conditions occur if the MPC value is over 40. The effect is more deposits occurring in the system.

Laboratory particle counting will differ greatly from online measurement using a portable particle counter; for example, a laboratory measurement may give 24/23/17, while an online measurement will be 16/14/10. The reason for this is that the solubility of varnish in the oil depends highly on temperature. When the oil sample is cooled down, the solubility limit in the oil is exceeded. This is mostly counted in the 4- and 6-micron ranges of the ISO code and results in a large difference when compared to the 14-micron code. Normally, there is a difference of up to four codes between 6 and 14 microns. As soon as varnish is present, this difference can be more than five codes in the laboratory particle count at room temperature. This exceedance of the solubility limit is reversible; when the temperature is increased, the varnish goes back into the solution.

How Do I Reduce the Formation of Varnish?

The ageing rate of the oil can be reduced through oil care measures. These include:

- Offline filtration: limits the growth in particle size.

- Dewatering: minimizes additive reduction due to leaching.

- Degassing: reduces contact with air and therefore with oxygen.

- Avoid electrostatic discharge in the oil and avoid ageing due to local temperature spikes and hot spots.

- Monitor the oil temperature balance in order to detect elevated friction in the bearing or overgrowth of the cooler early on.

- Regular oil analysis and tracking of the oil ageing help to avoid critical system states such as jammed control valves for the steam control of a turbine and unsafe machine operation.

Systems Used to Reduce the Effects of Varnish

Removal of varnish from system components is a relatively slow process. Oil ageing products are initially individual particles less than 0.1 microns in size. As a result, they can pass through the filter at first and initially do not impair the valve function. In the course of further oil ageing, or when the oil is cooled down (e.g., during a system shutdown), these particles agglomerate, become larger, and block the valve function and the filter medium.

The varnish removal systems are recommended to be operated over a long period of time or to be installed permanently. The removal of varnish in a system can be sensitive to elevated moisture levels in the fluid and to the presence of high levels of metal wear particles.

Several different technologies can be employed in a hydraulic system for removing varnish. Methods commonly used for the reduction or removal of varnish in a system are:

- Fine filtration

- Electrostatic purification

- Adsorption by a disposable media

- Chemical rinsing or flushing of equipment

The functional principle of offline filtration is that polymerized varnish in the range of 2 microns is removed by means of very fine filtration. An offline filtration system is installed on the hydraulic reservoir for continuous filtration. Using a cooler or chiller prior to a filtration unit to cool the oil allows the varnish precursors to form and be filtered out. The fine filtration will remove the free varnish and is often combined with a purifier or water removal unit.

Electrostatic dissipative (ESD) filter media was introduced to eliminate potential electrostatic charging problems in the filtration of hydrocarbon fluids. Extensive testing in controlled laboratory conditions and on operating equipment in industrial applications has shown this filtration media to eliminate filter damage and significantly lower charge generation compared with the typical glass-fibre filtration medium. Filter elements are made using a special mesh pack structure to reduce the charging of the fluid and are used in filter housings installed inline.

The use of offline filtration and ESD filter media can result in higher operational safety since sparking, oil degradation and the formation of sludge are eliminated. Longer oil service intervals resulting from fine filtration of the oil can lead to significant cost savings through fewer oil changes, filter element changes and system breakdowns.

Varnish mitigation units are designed to remove the soft contamination that are both in suspension and in solution. Typically, they are a simple design that is easy to use in a wide fluid temperature range. The functional principle of the varnish mitigation unit is to accumulate particles in the range of < 1 micron on an active surface of an ion exchanger. The advantage of accumulating even very fine particles is that the solubility of varnish in the oil is improved. As a result, the

oil becomes "varnish-hungry," and soft oil ageing products that have already been deposited on surfaces in the system are dissolved and absorbed by the oil. The varnish mitigation units don’t have any impact on removing any hardened oil ageing contaminates that have formed on the surface. The advantage of a varnish mitigation unit is that the structure of the ion exchanger provides a huge separating surface, and the operating costs of the system are reduced.

The chemical cleaning/flushing method is used for removing varnish utilizing cleaning chemicals that are typically circulated through the system to dislodge varnish from components. The chemicals are added to the hydraulic oil to soften and dissolve the insoluble materials. The flushing action suspends the hard deposits in the fluid, which are then removed with the fluid when it is drained from the system. This process is usually performed for several hours or several days, depending on the system size and the extent of the varnish build-up on components. The chemical cleaning method will require the system to be flushed with clean oil to remove any traces of the chemicals and then refilled with new oil before use.

Conclusion and Summary

Varnish is soft particles in the range of < 0.1 microns that form conglomerates and cause gel-like to hard lacquer-like deposits. The change in base oil has contributed to the increase of varnish formation in the oils. The formation of deposits is increased if the temperature drops and deposits are formed at "cold" points in the system or if the pressure increases.

In general, it is harder for more highly refined oils to keep varnish in solution. Identifying these oils is difficult; it is not immediately apparent from the oil datasheet. The consequences of varnish deposits are not usually traced to the altered base oil properties. Expensive and usually ineffective measures are taken, such as performing mechanical cleaning or replacing the oil.

The formation of varnish can be reduced through oil care. Filtration, dewatering, air removal, and degassing extend the oil lifetime. If there is a varnish problem, a varnish mitigation unit can help to remove "free" and "dissolved" varnish and reduce deposits in the system by improving the dissolving behaviour in the oil.