Bio-Based Versus Petro-Based Lubricants

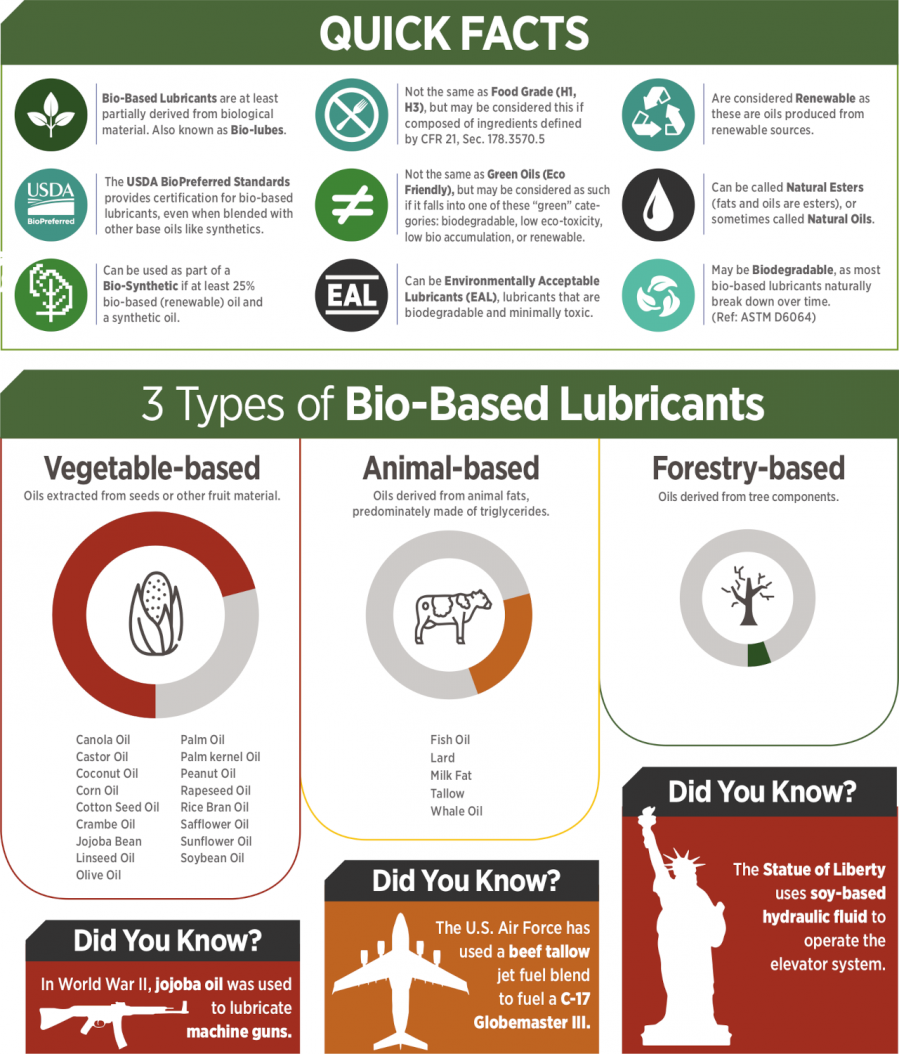

Base oils, the primary ingredients in a lubricant, are often first described by their origin, such as those either derived from biological materials (bio-based, such as plants) versus those refined from crude oil (petroleum, or petro-based) from the ground. These two base oil types, along with man-made synthetics, make up the three categories of base oils. Each represents a demand in the lubricant market, and each for good reasons. But there is a lot to understand about the differences between bio-based and petro-based lubricants, in how they are made and where they can be best used. Additionally, bio-based lubricants have numerous terms that are often used interchangeably or in a related context. The infographic to the right helps provide some clarity on these terms.

Base oils, the primary ingredients in a lubricant, are often first described by their origin, such as those either derived from biological materials (bio-based, such as plants) versus those refined from crude oil (petroleum, or petro-based) from the ground. These two base oil types, along with man-made synthetics, make up the three categories of base oils. Each represents a demand in the lubricant market, and each for good reasons. But there is a lot to understand about the differences between bio-based and petro-based lubricants, in how they are made and where they can be best used. Additionally, bio-based lubricants have numerous terms that are often used interchangeably or in a related context. The infographic to the right helps provide some clarity on these terms.

While the term petro-based is sometimes used, they are more commonly referred to as mineral-based or mineral oils. These are lubricants that are sourced and refined from crude oil. The complex refining process separates the petroleum products that can be used as a base oil from other products, such as fuels, and cleans up the base oil by removing the majority of the impurities. The properties of the original petroleum and the quality of the refining process produce a variety of lubricant characteristics that can be paired up with almost any lubricant application. These represent more than 80% of the world’s lubricant market.

On the other hand, a lubricant can be considered bio-based if it is partially or wholly extracted from natural biological sources. They are most commonly from plant seeds but may also come from animal fats or even some forestry products. These are also sometimes referred to as natural esters or natural oils. Whenever bio-based lubricants are identified as a vegetable-based oil, this refers to those from agricultural sources, such as plants. These also are often referred to as veggie oils and plant-based oils. Given their renewable source, they are popular for applications where a renewable product is desired or required. Like mineral oils, they must be refined but are often only marginally altered to help maintain some of their natural qualities, such as biodegradability. Because of their renewable and biodegradable properties, they are often considered environmentally friendly. Bio-based lubricants can further be considered Environmentally Acceptable Lubricants (EALs), based on VGP (Vessel General Permit) regulations provided by the EPA and defined as those which are biodegradable and minimally toxic and are not bioaccumulative.

Biodegradability gives all bio-lubes an important role anywhere the oil in an application has a higher risk of leaking into the environment, while still providing the minimum lubrication requirements. This makes bio-based lubricants a desirable option for applications in forestry, automotive, farm, railroad and power transmission for hydraulics, chains, gears, compressors, wire ropes and transformers, to name a few.

Vegetable-based oils are the most common amongst bio-lubes. While these are generally at least 50% more expensive than mineral oil, the benefits do not always favor the equipment’s primary lubrication needs. Depending on the sources of a vegetable-based oil, such as soybean, rapeseed, sunflower seeds or castor beans, they each contribute natural benefits, including lubricity, high flash point and high viscosity index. But most vegetable-based oils underperform in important factors like oxidation stability, low-temperature properties or long-term storage stability. This can be partly overcome by formulating with a higher quality sourced product and with more extensive refining processes (chemical modifications) and being properly additized for the application. Most vegetable-based oils rely heavily on antioxidants to delay degradation and hardening over time. Nonetheless, environmental benefits like biodegradability are generally considered a balanced tradeoff to the lubrication benefits like oxidation stability and thermal stability.

While mineral-based and vegetable-based lubricants have significant differences, they both have crucial applications in the industry. The more highly-refined mineral oils are most popular in industrial equipment, largely because of the long-term stability and reasonable price. The hydrocarbon structures of the petroleum product allow for good oxidative stability, thermal stability and suitability for a range of viscosities, making them a go-to choice for general grease applications, gearboxes, pumps, motors and most other industrial machines. Synthetics often provide more improved advantages over mineral oils or vegetable-based oils but come at a higher price. However, as more environmentally friendly lubricants become necessary, the vegetable-based oils will be a likely option. As lubricant manufacturers continue to innovate, we might even see animal-based or other biological sources find their way into the industry as the next leading bio-based lubricants.

| Vegetable-based Oils | Lubricant Application | Other Consumer Uses |

|---|---|---|

| Rapeseed Oil | Chainsaw bar | Biodiesel, cooking |

| Canola Oil | Hydraulic oil, tractor transmission fluid, metal working fluids, food grade lubes, penetrating oils, chain bar lubes | Biodiesel, detergent, photography, cosmetics, pharmaceutical, ink, paper, textile |

| Castor Oil | Gear lubricants, greases, hydraulic fluid, brake fluid | Paints, dyes, coatings, inks, cold-resistant plastics, waxes, polishes, nylon, pharmaceuticals, perfumes |

| Palm Oil | Rolling lubricant-steel industry, grease | Olive Oil Automotive Cooking, cosmetics, pharmaceuticals, soaps, lamp fuel |

| Jojoba Oil | Grease, lubricant applications | Cosmetics |

| Crambe Oil | Grease, intermediate chemicals, surfactants | Coatings, plastics, polyesters, nylon, cosmetics |

| Sunflower Oil | Grease, diesel fuel substitute | Cooking, cosmetics emollient |

| Cuphea Oil | Motor oil | Cosmetics |

| Linseed Oil | Cutting fluid | Coatings, paints, lacquers, varnishes, stains |

| Coconut Oil | Gas engine oil | Cooking, sunscreen, moisturizers |

| Peanut Oil | Less used | Cooking/frying |

| Cotton Seed Oil | General use | Cooking |

| Corn Oil | General use | Industrial cleaner, gas and diesel fuel, cosmetics, liquid soaps, shampoos, cooking |

| Animal-based Oils and Fats | Lubricant Application | Other Consumer Uses |

|---|---|---|

| Fish Oil | Less used | Drying oil, paints, varnishes, lacquers, resins, caulks, sealants, inks, putty, cooking |

| Tallow | Steam cylinder oil | Soaps, biodiesel, printing, candles, flux |

| Whale Oil | Watches, delicate instruments, | Soap, tempering steel, dressing for leather |

| Lard | Cutting oils, sulfurized lard as an additive | Soaps, cooking |

Acknowledgement to Ben Marquis as a contributing author.