How Borescopes Can Help Inspect Equipment

If you have been in the reliability realm for any length of time, you have probably been taught the importance of machine inspections; you may have even performed some. Sensory inspections using sight, sound, and smell are probably the most common forms of inspections. On more critical equipment, a thorough, in-depth inspection might be performed using tools such as oil analysis, thermography, or ultrasound. While these are great inspection tools, they only give us information about what might be going on in the machine from the outside. One tool that can allow you to get actual footage of the inner workings of the machine is a borescope.

If you have been in the reliability realm for any length of time, you have probably been taught the importance of machine inspections; you may have even performed some. Sensory inspections using sight, sound, and smell are probably the most common forms of inspections. On more critical equipment, a thorough, in-depth inspection might be performed using tools such as oil analysis, thermography, or ultrasound. While these are great inspection tools, they only give us information about what might be going on in the machine from the outside. One tool that can allow you to get actual footage of the inner workings of the machine is a borescope.

What is a Borescope?

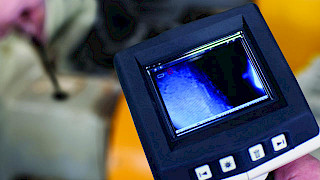

A borescope, in simple terms, is a viewing device wired to a camera at the end of rigid, flexible tubing. The camera is sent inside the machine via the tubing, allowing the viewer to inspect the machine parts and surfaces from outside the body (such as the case of a gearbox). These devices can be customized to fit the need of the application by changing the size of the camera, adding an articulating head to widen the viewing range, or even adding a light to the end for a better view.

Where Would You Use a Borescope?

Typical applications for borescope inspections include:

- Equipment with high criticality

- Equipment that cannot be easily repaired or replaced

- Equipment that, if a failure occurs, could result in severe harm or injury

- Machines where access is difficult, and inspection opportunities are limited

There are other circumstances, such as diagnosing a failure or looking for contaminants in the bottom of a hydraulic system, where a borescope might also be used.

A typical borescope with accessories for these types of situations might cost upward of twenty thousand dollars. However, some borescopes can cost less than one hundred dollars.

How to Inspect a Dry Dump with a Borescope

With this type of inspection being intrusive, it is essential that the component be de-energized and a LOTO (Lock Out, Tag Out) procedure be performed; this will ensure the safety of the technician and prevent damage to the camera. Once the machine is properly locked out, it is time to locate the best port through which to enter the sump. If you are inspecting gear teeth or a bearing, it might be best to remove the breather port or hatch and enter from the top; this will allow you to inspect more surface area as the camera is sent down. If you want to inspect the bottom of a reservoir, you might enter from a lower port, so you can more effectively scan the bottom portion of the sump. This is a great method to use if a reservoir has just been flushed and you are checking the cleanliness of the bottom of the sump.

How to Inspect a Wet Sump with a Borescope

There are many reasons that you might want to inspect a sump without draining the lubricant first, for instance:

- A large sump that is not feasible to drain for a quick inspection

- A sump that, due to its location, is difficult to drain

- A sump that requires frequent inspections between drain intervals

For most borescopes, a wet inspection isn’t as easy as probing into the sump and having a look around, as some camera heads are not fluid-proof. There is a work-around for this, though: a piece of PVC pipe with a polycarbonate window glued to the end will provide a good vehicle to get the camera into the sump without getting it wet.

What to Look for Inside

When inspecting a machine and its components with a borescope, you will be looking for the same signs of wear you would look for if you had taken the machine apart. Below are a few components and what you might look for:

Gears - The great thing about inspecting gears is the amount of surface that can be viewed. Checking the gear teeth can provide a wealth of information pointing to the condition of the gear. Gear teeth should be inspected for any sign of abrasive fatigue and chemical wear. The gear teeth and side surface of the gear need to be inspected for cracking as well; if any cracking is found, it should be measured (if possible) and checked for any growth on the next inspection.

Bearings - With the way elements are positioned in a bearing, there is usually only a small amount of surface area that can be inspected. There are still many things we can inspect, though, such as positioning (to make sure the bearing is still intact), bearing seals and the rolling elements themselves. Rolling elements should be inspected for the same types of wear as a gear, with special attention paid to any type of pitting.

Sumps - It might be a little overwhelming when inspecting tanks and sumps. Because of their size, there can be a lot to look at. A sump’s walls should be inspected for varnish and pitting, while the sump floor should be inspected for sludge and any solid contamination that lay on the bottom.

Seals - Confirm that seals are still seated and inspect for any obvious ingression or damage.

Summary

There is a great deal of information we can gather from performing inspections using borescopes without having to disassemble a machine. These inspections can even validate data from another inspection tool such as thermography or oil analysis. With the ability to save pictures and film after each use, borescopes are a great tool for a reliability program.