Taking the Guesswork Out of Filter Selection

By now, organizations that have advanced reliability and maintenance programs understand the intrinsic value of lubricant cleanliness. Noria and many others have published extensively on this subject. The business case is rock solid: the cost of preventing oil from becoming dirty (exclusion and removal) is a small fraction of what machine repairs and downtime will cost down the road. The sad truth is that many asset owners are under the false impression that their filters are doing a good job and their oils are clean enough.

By now, organizations that have advanced reliability and maintenance programs understand the intrinsic value of lubricant cleanliness. Noria and many others have published extensively on this subject. The business case is rock solid: the cost of preventing oil from becoming dirty (exclusion and removal) is a small fraction of what machine repairs and downtime will cost down the road. The sad truth is that many asset owners are under the false impression that their filters are doing a good job and their oils are clean enough.

Just as it is true that not all lubricants are alike, the same holds true for filters. Filter manufacturing is a very competitive and diverse industry from the standpoint of cost, quality and performance. Owners of large equipment fleets can spend well over $1 million per year on filters. Industrial plants with extensive asset lists can face a similar filtration spend. A single filter element used on a large circulating oil system can cost more than $1,000.

While there are commodity (economy grade) filters of all types to choose from, as with many products, the greater value and quality often come from selecting the premium option at the high end of the price range. Yet, most premium high-performance filters can look very similar to cheaper, lower cost filters at first glance. Published data on filter performance by their suppliers is often embellished or out-of-date. After all, a filter supplier would never publish anything other than stellar performance data, and this data is usually the product of their own laboratory.

My background in filter testing runs deep. Before Noria, I was the CEO of Diagnetics, Inc., the world’s largest manufacturer of filter test stands. These test stands evaluated filter performance to SAE and ISO standards. We also tested thousands of filters on our equipment. During that time, we became very aware of a common discrepancy between measured filter performance and the perceived quality of those same filters among the user community.

Getting the Biggest Bang for Your Filter Buck

Just like lubricant performance testing, in many cases, it is wise to get filters tested by an independent laboratory. For instance, if you have three filter brands you are considering, it would be advisable to get an objective, unbiased confirmation of the following questions:

- Which filter gets the oil the cleanest (capture efficiency across the life of the filter)?

- Which filter lasts the longest (dirt-holding capacity)?

- Which filter has the lowest flow resistance (pressure-flow performance)?

- Which filter is manufactured to the highest quality and fabrication integrity (free of random defects)?

Of course, you don’t need independent testing to answer the final question: which filter is the cheapest?

Fortunately, there are excellent standards available for answering questions 1-4. Sadly, testing filters to these standards has not been widely available to the user community. These standards are:

- ISO 2942: filter fabrication integrity (quality)

- ISO 16889 and ISO 4548/12 (performance): particle capture efficiency, dirt-holding capacity, flow resistance

- ISO 23369:2021 (performance): similar to ISO 16889 but for filters exposed to cyclic flow and other real-world conditions

There are numerous other test standards available, but these offer the greatest opportunity to optimize filter selection from the standpoint of value and performance. Together, these standards work towards achieving consistent lubricant cleanliness (within the target cleanliness) at the lowest possible cost.

What Multipass Filter Testing Looks Like

A multipass test stand is used to perform all the tests listed above except for fabrication integrity. This can be done for filters of numerous different sizes, configurations, and flow rates. A multipass test stand is a highly engineered machine with many circulating loops, a contaminant injection system, two online optical particle counters and a 100:1 continuous dilution system (to ensure particle count accuracy). See Figure 1 for a visual idea of the engineering and science behind standardized filter testing.

The forward-facing “bench side” of the test stand has three circular funnel-shaped reservoirs, as shown in Figure 2. The larger reservoir (far right) is the injection system reservoir that supplies a precisely metered distribution of particles (e.g., ISO Medium Test Dust) to the filter test loops during the test cycle. Filter testing can take several hours from start to completion. Together, the filter test loops can handle flows ranging from 0.26 gpm to 106 gpm (1 L/min to 401 L/min).

To start a test, the filter is mounted above the shallow rectangular sink on the left using the hardware corresponding to the required flow rate. In Figure 4, a small spin-on filter is shown mounted to the low-flow rate test loop. The high-flow test loop is positioned above. The lower left hardware shows a flat-sheet holder for testing swatches of filter media in the same way a cartridge or spin-on filter might be tested. Flat-sheet testing evaluates the performance of the media only, not the entire filter element collectively.

Before each test, the filter flow rate and terminal pressure drop are entered manually at the computer control station. Most other operating conditions, including contamination injection rate, temperature, dilution ratio, etc., are predetermined by the standard and operating system. Other test protocols would be required for cyclic flow testing (ISO 23369).

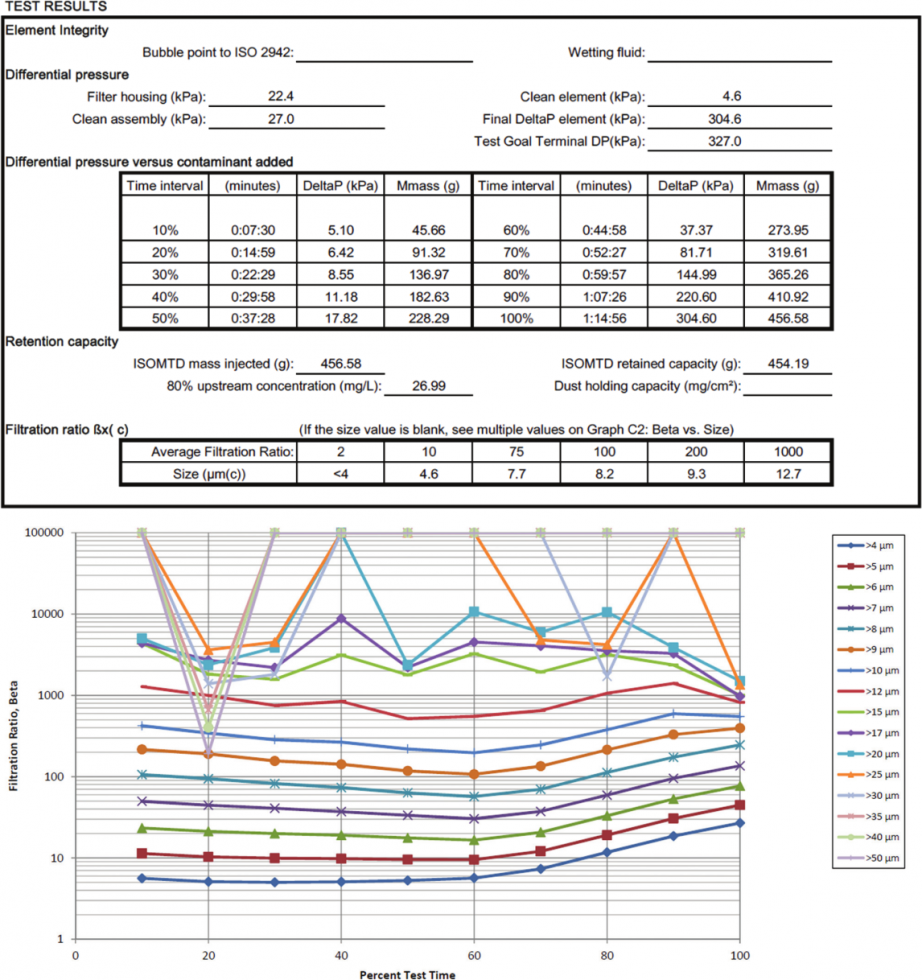

Multipass testing enables filters to be tested to an international standardized protocol. This enables published data to be compared apples-to-apples to other candidate filters tested using the exact same protocol. It also removes subjectivity and differences in data interpretation. For instance, what do you understand when a filter is represented as being 10 microns nominal? How about 10 microns absolute? Or Beta (10) of 10? Multipass testing is a consensus standard written by industry peers. As such, it removes this uncertainty and random interpretations of such performance claims. Figure 6 shows data from a sample multipass test report to ISO 16889.

Fabrication Integrity Testing

You may be surprised to hear that each filter that is sold is a filter that has never been tested. Multipass filter testing is destructive, time-consuming and relatively expensive. It is also really good at assessing the first three performance assessments in the above list. While many filter companies may share or publish multipass filter test data with customers, often these tests were last performed years ago. Filter media changes, as do other manufacturing specifications. These differences influence test performance in a variety of ways.

Fabrication integrity testing (also known as bubble-point testing) presents another option and is often done on each filter before multipass testing. Fabrication integrity testing is non-destructive and relatively cheap, although it is rarely done on filters that are sold. To perform this test, the filter element is submerged in a bath of alcohol, and air is slowly metered into the center of the filter. The increasing air pressure is monitored using a standard monometer. When the first stream of air bubbles emerges through the filter element (point of least resistance), the pressure reading of the monometer is noted. This is the bubble point.

The higher the pressure, the greater the filter’s fabrication integrity. There is a good correlation between the bubble point and the mean pore size of the filter media. Most filters that fail the bubble point test are not marginally defective but instead exhibit major issues, including damaged filter media, seam cracks and defective end-cap adhesive seals. You may be surprised to learn that at least 10% of all new oil filters (regardless of the application) will fail the bubble point test in this way. This statistic can vary between filter brands, type and quality (e.g., price point).

Using Testing to Reduce Your Filtration Spend

The value of incorporating filter testing when planning your purchases is best demonstrated using a simple financial analysis. Let’s say your company spends $152,000/year on a single type of hydraulic filter. You are aware that there are at least three filter suppliers that make comparable filters (size, configuration and performance). The prices of these filters are different. In the past, the low-cost option was selected by procurement. For the purpose of this analysis, we’ll assume the capture efficiency (Beta Ratio) of these three filters to be the same. Which one should you select? The lowest price? Let’s do the math. See Figure 8.

Getting a filter’s dirt-holding capacity is rarely as simple as going to a website or looking at a product data-sheet. In fact, I’ll bet you can’t find it anywhere. Why is that? ISO 16889 (industrial oil filters) and ISO 4548 (diesel engine oil filters) both include dirt-holding capacity as a standard reported value.

In the example of the three candidate filters, we’ll estimate that 200 kilograms of dirt must be removed over a year’s time for the entire fleet. In the table to the left, the differences in filter price are shown. The three filters were tested independently on a multipass test stand, and the dirt-holding capacities were found to be 250, 160 and 125 grams, respectively. Based on the 200 kgs of total dirt, the number of filters required is 800 for the premium high-priced filter and 1,600 for the economy brand.

Also included in the financial analysis is the labour cost of replacing a filter. I used $25 per filter, but there are many other hidden costs I did not include. These include purchasing, stockroom and handling, planning and scheduling, used filter disposal, waste oil handling and disposal (oil from inside the filter), record keeping, etc.

When the price per filter (including labour) and the dirt-holding capacity are compared together, the economical best choice is the premium, long-life filter at a savings of roughly $72,000 per year. Please note that my data is hypothetical. Don’t assume the premium filter to always be the long-life filter. Do the testing and get real data. The cost of testing these three filters would be less than $4,000 - a small fraction of the potential savings.

As mentioned, testing reveals other critical performance differences between filters as well. The three most important are particle size retention (how clean will the filter get your oil), flow resistance (affects energy consumption) and fabrication integrity (likelihood of random manufacturing defects). A larger number of filters will be needed to get statistically meaningful data for fabrication integrity. These other performance factors influence the service life of machine components (bearings, pumps, gears, etc.), labour and material cost of repairs, downtime costs, energy consumption costs and much more.

| Brand A | Brand B | Brand C | |

|---|---|---|---|

| Filter cost (per element) | $125 | $110 | $95 |

| Tested dirt-holding capacity (ISO 16889) | 250 gms | 160 gms | 125 gms |

| No. of filters required to remove 200 kgs of dirt (fleetwide) per year (filters changed based on pressure drop) | 800 | 1250 | 1600 |

| Annual filter consumption cost | $100,000 | $137,500 | $152,000 |

| Filter change labor cost (est. $25 each) | $20,000 | $31,250 | $40,000 |

| Total annual cost (filter and labor) | $120,000 | $168,750 | $192,000 |

| Savings compared to the economy Brand C | $72,000 | $23,250 | $0 |

Where to Start

If I had a fleet of machines and a large annual filter consumption bill, I would compile a list of filters consumed in high volume and those that individually cost the most. This is your Cost Factor List. Next, I would look at mission-critical machines and the filters used there. For such machines, there is a need for far greater performance to ensure reliable and consistent contamination control. This is your Criticality Factor List. Many filters will appear on both lists.

By ranking the filters from two lists, you focus on testing where the economic opportunity is the greatest. For more information on how to get your filter tested, contact Noria Corporation.