How to Conduct Machine Inspections and Put Inspection Data to Use

In today’s world, making data-driven decisions lies at the foundation of a top-tier maintenance program. A good chunk of this data is collected through machine inspection, whether it’s checking oil level in a sight glass or performing a more advanced inspection like measuring bearing friction with ultrasonic tools. When gathered correctly and consistently, the data from machine inspections can be a powerful tool to unlock higher profit margins, less downtime and longer machine life.

In today’s world, making data-driven decisions lies at the foundation of a top-tier maintenance program. A good chunk of this data is collected through machine inspection, whether it’s checking oil level in a sight glass or performing a more advanced inspection like measuring bearing friction with ultrasonic tools. When gathered correctly and consistently, the data from machine inspections can be a powerful tool to unlock higher profit margins, less downtime and longer machine life.

Why Prioritize Machine Inspections?

It may seem tedious to record and analyze data from every individual inspection, but doing so pays off tenfold. Regular machine inspections allow you to improve your understanding of each individual asset, gaining in-depth knowledge of the unique components of a machine. Aside from gathering more data to plan maintenance and repairs, this strategy can help you use your intuition to service machines. For example, if you know a specific asset is dangerously low on grease every time you perform an inspection, you’ll know to increase the grease interval and inspect it more frequently.

Who Should Perform Machine Inspections?

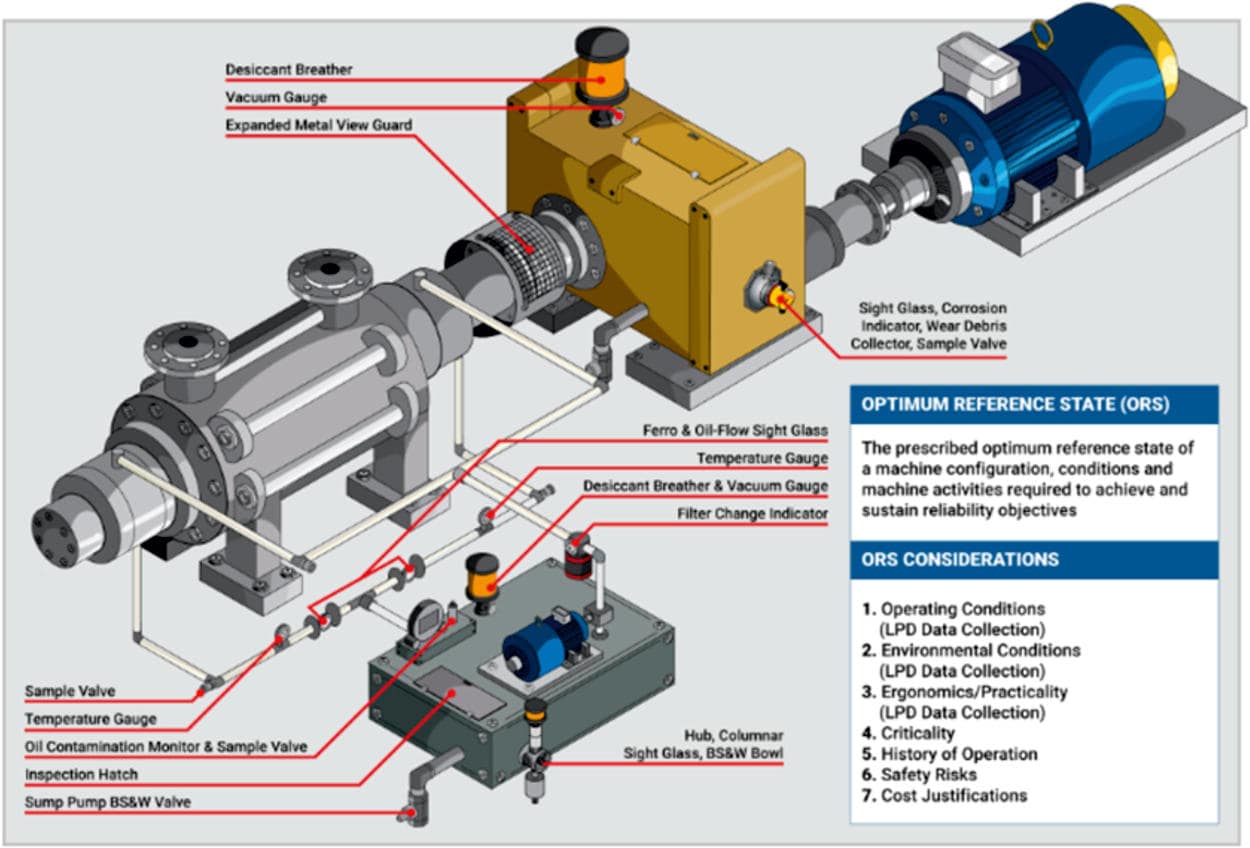

Recognizing the signs or symptoms of machine failure is a required skill for those who work with machines and are responsible for their maintenance and care. Inspections should be conducted by trained operators, technicians, millwrights or others who have frequent access to machines; however, they are often performed without the required skills, motivation and frequency. Checklists are helpful when completing these tasks — these can be posted on or near the machine itself, but the ideal location is within your lubrication routing software. The range of inspections will vary considerably depending on the machine type and how it has been accessorized for inspection activities.

Getting Started with Regular Machine Inspections

An inspector who is eager to determine the state of machine health — good or bad — needs to ensure machine readiness before getting started with regular inspections. Start by compiling a list of machine faults and root causes you want your inspection program to reveal. This is generally a list of all the things that could go wrong that you definitely don’t want to go wrong without early warning. If you’re currently running a maintenance program without formal procedures for machine inspections, remember it’s okay to start small with a few routine inspections and build over time. Let’s look at what goes into a simple oil level inspection and how you can use the collected data to determine machine health and create an action plan.

Oil Level Indicator Inspection

A sudden change in oil level, either up or down, or the presence of water or sediment in oil is a telegraphed alert that something is wrong. This “something” could potentially be serious. Deferring maintenance or ignoring this alert could lead to a costly repair and longer downtime in the future. The frequent examination of quality oil level sight glasses by trained inspectors is a sound condition monitoring practice — perhaps the most important of all lubrication-related inspections.

How to Perform

Use level gauges, sight glasses, dipsticks or inspection ports/hatches to determine the oil level. Additionally, a bottom, sediment and water (BS&W) bowl can be used to view sediment, water, foam and wear debris, making it the ideal tool for an oil condition inspection. A slight drift in oil level (up or down) can be a critical alarm. In some rare cases, it would be beneficial for an oil sight glass to be placed on both sides of a centrifugal pump. If the pump is not centered in the casing, the oil level will not read correctly in the sight glass due to oil movement by the bearing. However, if you have two level gauges, an average of the two readings will give a better estimated oil level.

When you perform an inspection, it’s important to not just look at a bearing, seal, coupling or pump. Instead, examine these components with a keen and probing eye. Seek to extract information and translate machine “language” into prescribed activities and instructions that stabilize reliability. This technique, known as Inspection 2.0, ensures no machine inspection is wasted time.

What to Look For

Whether oil goes up or down, any sudden change in the oil level requires troubleshooting in search of the cause and corrective action. Just adding more oil or removing excessive oil is an activity of treating the symptom, not the cause. It’s true that some oil level changes are rather common and quickly understood. For instance, if oil goes sharply down, you might have a conspicuous leak (internal or external) that can be easily found and corrected. Inversely, a rising oil level may be due to the introduction of new fluids. For example, perhaps someone added too much oil, or another fluid like a coolant or fuel has entered the system, raising the oil level.

Causes of High Oil Level

When oil levels rise above the acceptable range, usually something new has been added, i.e., a new fluid, but there are other possible causes.

-

Too much makeup fluid — Adding makeup fluid without carefully watching sight glasses can cause over-lubrication.

-

Oil drain back — If the fluid is topped off while the machine is running, the oil level can climb; when it stops, oil drains back from gears, bearings, oil galleries and distant zones or oil ways.

-

Aeration and foam — Such conditions can double or triple the apparent oil level.

-

Internal leakage — Various sources of internal leakage can cause other nearby fluids to invade the sump. These include coolant, washdown fluids, fuel, heat transfer fluid, hydraulic fluid, grease and process fluids. Oil analysis can identify these

Causes of Low Oil Level

This is usually caused by leakage, but there are other reasons.

-

Out-leakage — This is an alert to examine the machine for any visual sign of oil leakage to external surfaces (oil exiting the machine).

-

Internal leakage — If no out-leakage is observed, are there other internal pathways and compartments where the oil might have gone? Look for rising fluid levels in these zones and compartments.

-

Gear climbing — Oil lifters, including paddle gears, slingers/flingers and the rotation of moving parts (gearing in particular), all draw oil out of sumps and reservoirs and lower the apparent oil level during machine operation.

-

Oil pump out — After startup, oil reservoirs can go down as the pump fills system lines and cavities such as gear cases, bearings, oil galleries and distant oil ways.

-

Bleed purge — Hydraulic and circulating systems often have bleed valves that, when opened, allow trapped pockets of air to purge and become replaced by oil. This draws the oil level down in the reservoir.

-

Aeration and foam — Foam lowers the liquid portion of level gauges, sometimes substantially. When the foam collapses (e.g., when the machine is at rest), the correct level should return unless foam was pushed out of vents and other headspace openings.

-

Excessive misting and volatilization — This is a form of out-leakage from various causes, such as the wrong oil (e.g., wrong viscosity), high temperature, excessive agitation, headspace vacuum, atomization/sprays or aeration.

Documenting Data

Depending on the work experience of the lube staff and the available time intended for the lubricating tasks, the lubrication operator should provide the following information about the machine condition:

-

Visual analysis of the lube oil condition (in this case, the oil level and signs of contamination)

-

Lube oil system condition (oil leaks, tank cleanliness and superficial condition, oil filters, oil drains, etc.)

-

Mechanical condition of the machine (vibration, noise, bearing temperature, etc.)

-

Miscellaneous (information on new machinery installed at the plant, reports of other problems in the plant that affect the lubricated machines, etc.)

This data should be added to the system database as soon as possible to help promptly solve any problems detected within the machines. The faster the information is added to the system, the faster the plant’s reliability engineer can analyze the machine condition with more advanced predictive technologies.

Using Data to Make Decisions

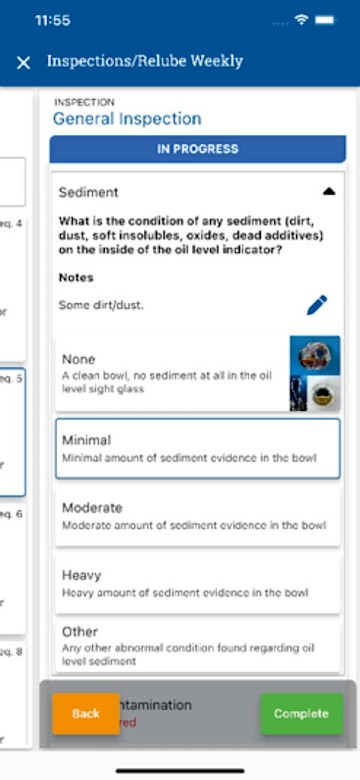

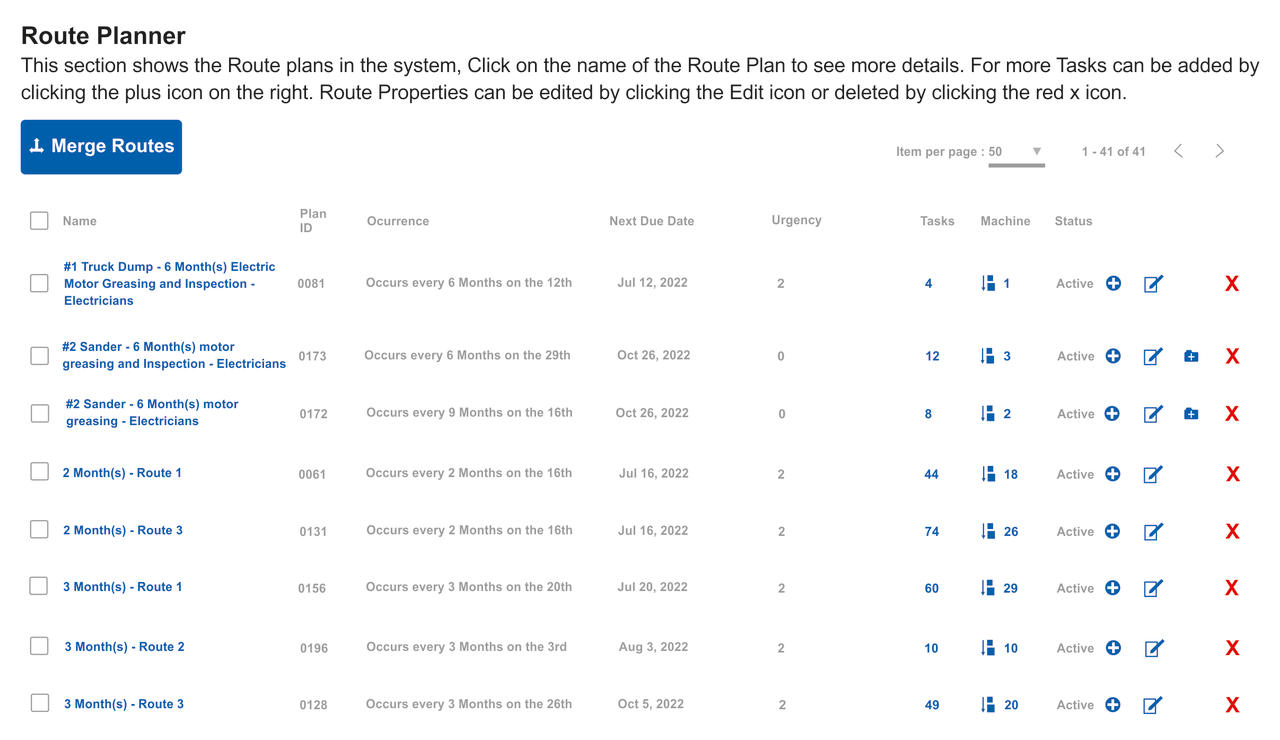

When it comes to performing machine inspections correctly, having an organized platform to record and analyze data is key. This is where a lubrication program management platform comes into play. This allows the user to document detailed inspection data for each asset and view trends that reflect machine health over time.

With the right lubrication routing software, you can automatically include every lube point that has been found to be in poor condition in the next planned route. With this automatic process, the lube points that are deficient are revised more frequently until the correcting actions have the desired effect. An alarm system for the machine’s lube condition can also be implemented based on the information collected from the lubrication routes.

From this starting point, there are multiple strategies that can be implemented to optimize the lube-route schedule based on the machine condition and how often anomalies are detected. If an integrated system is employed, other information about the machine status can be used to improve the schedule and more frequently inspect the machines that are in poor condition.

The lubrication frequency of points in poor condition that need to be inspected again will correspond to the maximum number of lube points included in the same processing unit of the plant. For example, let’s say the available lubrication frequencies in one unit will be a multiple of a fixed number of days (15, 30, 45, 60 days, etc.). This method allows the mechanical workshop to manage only the planned work orders. The difference is that the number of lube points will be slightly increased depending on the machine’s oil status.

There are other improvements that can be implemented when tailoring lubrication routes and PMs based on the information collected from field personnel, including:

-

The status of the lube point inspected in the last route can be included in the guideline table for the next route. This allows personnel to pay more attention to the most critical points.

-

Any valuable information or pending work orders on the machine can be included in the guideline table and taken into account by the lube operator.

-

Any automatic alarm or advice intended for taking further action, like oil analysis, vibration measurements, etc., will improve the performance of the system.

-

Other information based on the machine type and the organization of the reliability and maintenance departments can be utilized.

Bottom Line

Machine inspections are a fundamental part of a well-rounded maintenance program. However, they only prove to be effective when the data is recorded and analyzed correctly. If you’re building or revamping your inspection program, having a lubrication program manager with routing capabilities can be a catalyst in getting desired results. This software creates an organized space for data input and assists with the analysis of the data over time, allowing you to service your machines efficiently and optimally.