Are You Ready? Supply Chain Problems Spark the Need for Backup Lubricants

In the past couple of years, Noria has received a slew of requests for help from large users needing backup lubricants for critical applications. Disruptions in lubricant supply have been the main impetus for these inquiries. As we talked to many industry contacts, we discovered that the problem is widespread. A shortage of additive stock appears to be the main culprit, but in other cases, base oil supply-chain issues were responsible.

Some users have been attempting to deploy stopgap solutions to reduce oil consumption. This includes extending oil drains and doing top-ups as opposed to oil changes. Of course, one way to get oil to last longer is by reducing additive and base oil distress using the clean/dry/cool strategy. In other cases, supplemental additives can be reconstituted into the aging lubricant - something like a booster shot. However, that assumes those additives can be made available.

Some users have been attempting to deploy stopgap solutions to reduce oil consumption. This includes extending oil drains and doing top-ups as opposed to oil changes. Of course, one way to get oil to last longer is by reducing additive and base oil distress using the clean/dry/cool strategy. In other cases, supplemental additives can be reconstituted into the aging lubricant - something like a booster shot. However, that assumes those additives can be made available.

It may also be wise to keep larger reserves on hand by doing away with just-in-time inventory management until reliable supplies return. Note that the prolonged storage of lubricants may present acute problems as well. Do your homework on storage stability issues from past articles found at machinerylubrication.com.

However, these strategies may be nothing more than a temporary fix to chronic future problems. Changing to a more reliable lubricant supply may be your best bet. At a minimum, you need to be “at the ready” with a backup lubricant that is immediately deployable in your plant equipment when the need arises. Don’t wait until you’re down to your last drop; think through the worst-case scenarios and the contingency plans or remedies that you have at your disposal.

Risks From an Abrupt Change to a Backup Lubricant

If a lubricant change is possible (or, for whatever reason, unavoidable), it is best to get a firm grasp on the potential risks. Your ace in the hole may not be all that it seems. Verification is absolutely necessary. Fortunately, the industry has considerable experience and understands the risks associated with a sudden changeover to a backup lubricant. These include:

-

The backup lubricant was incompatible with the previous lubricant, and some mixing was unavoidable (or not properly avoided). The incompatibility resulted in lubricant performance defects and associated reliability consequences.

-

The backup lubricant was incompatible with internal sediment, sludge and/or varnish.

-

The backup lubricant was incompatible with internal machine surfaces (paint, surface treatments, filters, elastomers, caulking, adhesives, etc.). Some aggressive lubricant additives can leach sensitive metals (tin or copper, for instance).

-

The backup lubricant was incompatible with operating conditions and exposures (temperature extremes, contaminants, gases, process chemicals, washdown sprays, coolants, etc.).

-

The backup lubricant had performance weaknesses or drawbacks that the previous lubricant did not. While some characteristics of the new lubricant may be superior to the previous lubricant, many others could exhibit substandard performance.

The highest risks coming from backup lubricant changeovers are associated with:

- Old equipment (long service with the previous lubricant)

- Unknown additive chemistry and limited compatibility testing performed

- High machine duty and criticality Complex lubricant formulations

Verify Compatibility in Advance

There are numerous industry standards that provide guidance on compatibility testing (ASTM, FTC, etc.). The typical protocol for oil (e.g., ASTM D7155) involves preparing binary mixtures of lubricants with questionable compatibility. Mixtures such as 50:50, 95:5 and 5:95 are often used, but this can be modified to better match the target application.

According to ASTM D7155, the mixtures must go through a short bedding-in time at an elevated temperature. This allows the base oil and additives to chemically and physically interact, after which the mixtures are ready to be inspected and tested further. If floc, sediment, clouding or discolouration develops from the mixtures, the lubricants are confirmed to be incompatible (tier-one test) without further analysis. If this doesn’t occur, a sequence of additional testing tiers will be required. The exact tests and passing conditions associated with these supplemental tiers must be thought through carefully (lubricant, application and exposure dependent).

Machine criticality plays a vital role in this decision, along with other factors. A lubricant specification can be used as the baseline for the supplemental tests, or the performance listed on the new lubricant from its product data-sheet can be used. However, a well-constructed specification is necessary for critical applications. Example performance tests can include filterability, air-handling ability, water-handling ability, film strength, oxidation stability, corrosion suppression, etc.

The selection of tests for the supplemental tiers is largely driven by service life needs (of the oil) and the critical performance needs in the target machine application. Again, standardized test methods can be employed, especially relating to elastomers and surface treatments. The risks relating to chemical exposures might include certain gases (refrigerants, ammonia, hydrogen sulfide, etc.), fuel, coolants, process chemicals, etc. Custom or modified standardized testing may also need to be performed to assess their compatibility.

Developing an Oil Drain and Flushing Strategy

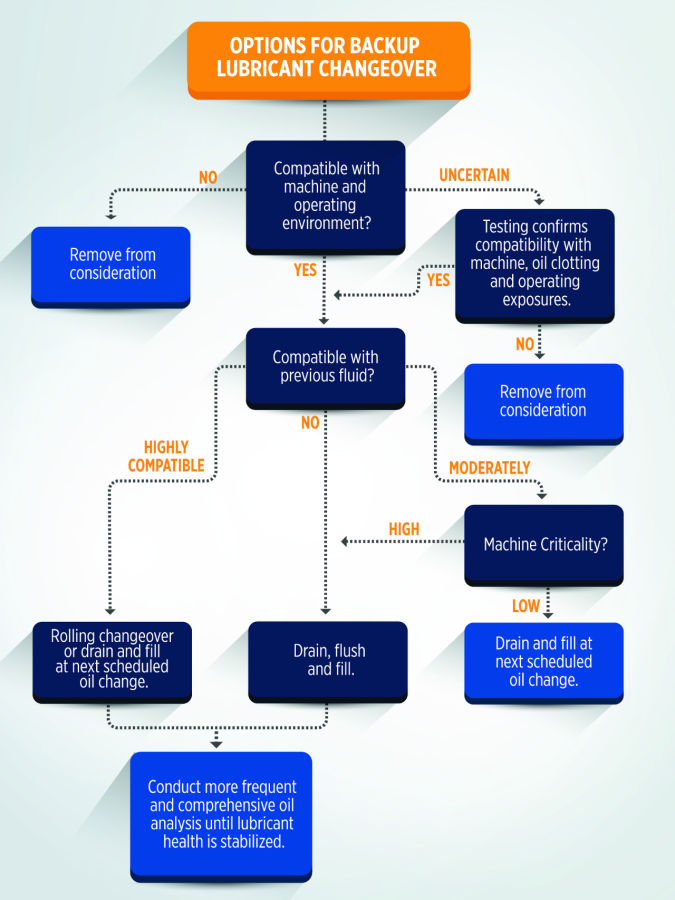

For obvious reasons, a changeover is strongly discouraged if incompatibility is found (or there is uncertainty) between the new backup lubricant and the machine (seals, for instance) or the operating environment (e.g., process gases) (see Figure 1). If a changeover is still unavoidable, seek other lubricant options to mitigate the risks and consequences. Do not underestimate the importance of this.

Should incompatibility only be found between the lubricant mixtures (not the machine or operating exposures), a changeover can usually be successfully performed. However, this requires special precautions, such as the complete removal of the previous lubricant and the decontamination of sediment, sludge and varnish.

The greater the danger, the more rigorous the drain and flushing procedure should be. We can relate this to the definition of risk, which is the probability of a compatibility problem multiplied by the consequences of incompatibility. High lubricant incompatibility (determined from testing) relates to the probability of a problem occurring, and high machine criticality defines the consequences of failure (lubricant and/or machine). Criticality includes such things as the cost of repair, lost production, the cost of flushing and safety risks.

Where the danger is the highest, drain the system completely of all remnants of the previous fluid. Look for trapped cavities of fluid in heaters, coolers, off-line loops, hoses, filters, low-point traps, line extensions, etc. Even after the drain is complete, the oil will still occlude to the internal machine surfaces. These wet surfaces, along with the presence of sludge and surface deposits (including the varnish), are high risk.

Follow the drain with a displacement or chase fluid to carry away the remaining previous oil. The displacement fluid is sacrificial and, as such, needs to be completely compatible with the final fluid charge and relatively inexpensive. A low-viscosity base oil is sometimes used, or perhaps even a transformer oil. Heating the displacement fluid and passing it through all internal fluid zones at high velocity (high Reynolds Number) gives the best results. Many independent companies offer flushing services that are worth considering.

Greatest Changeover Dangers

If machine surfaces fail to clean completely, a chemical flush may be required. This can be added to the displacement fluid at a concentration of 5%-10%. One common product sold by DuBois Chemicals is Step-One cleaner (also branded and available from other lubricant suppliers). It is not a solvent but a calcium-sulfonate detergent product blended in a mineral base oil that has been found to be very effective. One drawback is that this cleaner must be completely removed from the system before the final lubricant is introduced. This is typically done with yet another displacement fluid.

Rigorous Post-changeover Monitoring

After the flush has been completed and the final oil charge added, combat the law of unintended consequences by using a post-changeover monitoring strategy. Accelerate oil analysis and other machine inspections (foam, cloudy sight glasses, high temperature, discolouration, noisy operation, etc.) - test for foaming tendency and demulsibility characteristics. Also, don’t forget to change lubrication procedures to include the new lubricant for top-ups and oil changes. Be sure to re-label the machine with the correct new lubricant as well.

| Problem | Greatest Danger | Consequences | Controlling the Risk |

|---|---|---|---|

| Loss of oil clotting/packing | Old machines; switching from mineral oil to formulations with esters, detergents, dispersants and other polar additives | Oil leakage (both internal and external) and potential starvation | Perform a chemical flush and repair leakage before the machine is returned to service |

| Impaired seal performance (e.g., dimension change, structural change, deterioration, compression set issues, etc.) | Old machines; switching to a synthetic lubricant that has a sharply different aniline point than the previous lubricant | Oil leakage (both internal and external) and potential starvation | Run tests for compatibility to elastomer types used in the machine; repair/ replace old and worn seals |

| Sludge mobility (sludge and deposits become mobilized by a change in lubricant chemistry) | Old machines; switching from mineral oil to formulations with esters, detergents, dispersants and other polar additives | Clogged oil flow through glands and orifices resulting in starvation and accelerated wear | High-velocity flush, chemical flush and other flushing methods are needed to purge the system of sludge and deposits before a new lubricant is introduced |

| Impaired lubricant performance due to clashing additives and base oils | Incompatible lubricant mixtures such as acid/ base reactions | Possible reliability issues from:

|

Complete drain and flush of all remnants of the previous lubricant |