How to Detect, Treat and Prevent Microbial Contaminants in Lubricants

What are Microbes?

What are Microbes?

Also called microorganisms, microbes are microscopic living organisms that can be beneficial or detrimental to human health. Microbes can be grouped into five major categories: viruses, bacteria, archaea, fungi and protists. As humans, we currently have millions of microbes throughout our body, and current estimates suggest there could be up to 1 billion different species of microbes on earth.

If you have ever taken level one training with Noria (MLT I or MLA I), you will have heard us compare industrial machinery to the human body: “Take care of your machinery as if you were taking care of your body.” After COVID-19, we are all well aware of what a virus looks like, how it is potentially transmitted and how harmful it can be to certain people. We can relate that to how detrimental microbial contamination can be in an industrial oil.

Detection

When we start feeling sick, we need to perform some basic diagnostics before we can start healing; a similar approach should be taken with lubrication. What are the symptoms, what is the root cause of the symptoms and how do we fix it? Here are some of the symptoms of microbial contamination:

You should be aware of certain characteristics that may produce a high probability of microbial growth: high water levels, stagnant areas, low flow and dark areas. Now, while these symptoms and characteristics may provide a warning, they aren’t necessarily the end all be all; most of the diagnosis of microbial contamination is found through laboratory analysis.

Generally, microbial contamination will produce acid. This happens because the microbe wants to grow and reproduce, and for any living organism to grow and reproduce, it must eat and build energy. What is in oil that acts as an energy source or food for the microbe? Carbon atoms from the hydrocarbon molecules. Once these structures are broken down and have open bonds, they are more likely to attract oxygen, which produces oxidation, a byproduct of which is acid formation.

Treatment: Reactive Maintenance

I keep referring to the level one training that we provide; in that training, you will hear about keeping oil “clean, cool and dry” no less than a hundred times (with “clean” and “dry’ being the two most important factors as far as microbial contamination is concerned).

![]()

Plugging the filter with a gelatin-like substance

Rapid oxidation without overheating, especially in turbine oils

Water demulsification test failure (ASTM D1401)

Failure of foam characteristics tests. (ASTM D892)

Water content > 500ppm

Gelatin-like substance in the columnar level gauge

Poor response of unit controls

Excessive difficulty removing water from oil

High or increased acid number

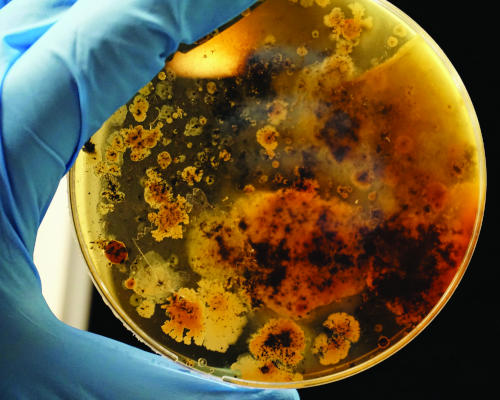

Laboratory culture growth tests.

As previously stated, microbes need a dark and dank area to thrive. To remember how a microorganism works, it helps me to think of a microbe as a vampire: it needs a stale, moist, dark environment to live in and sucks the blood (oil) from our machines. Unfortunately, however, garlic and a crucifix won’t do much good against microbes; you’re going to need to utilize biocide additives to neutralize the growth of bacteria and eliminate it.

Once eliminated, the oil needs to be dried out as much as possible. To clarify, when I say “dried out,” I mean removing as much water as possible. If drying isn’t possible, then we have to take drastic measures and drain the contaminated oil out of the reservoir. Once drained, a thorough flush of that reservoir with a compatible low-viscosity oil that has a biocide additive must be performed.

Prevention: Proactive Maintenance

We need to proactively ensure that we are aggressively preventing water ingress. This can be done by utilizing the right breather or, in some cases, dry instrument air. Make sure that all of the seals and ports are water and air-tight. Install quick connects for draining, filling, topping off and filtering to help prevent contaminant ingression. Use the correct filters with precisely calculated beta ratios and efficiency. Set target cleanliness and dryness goals for your critical machinery (remember, microbe growth can potentially occur at water levels > 500ppm). Lastly, and most importantly, perform frequent oil sampling, inspections and condition monitoring. This will ensure that if microbial growth starts to happen, you can catch it before it is too late. Hopefully, this helps you approach microbial contamination in a calculated manner and helps your machines run better and longer.