The Value of a Platform Dedicated to Lubrication Program Management

With an industry increasingly focused on improving machine reliability through the deployment of best practices in lubrication and oil analysis, there is a need to establish better management tools to accomplish these objectives. Providing dedicated software solutions for maintenance and reliability professionals to manage lubrication is particularly critical with the advent of new innovative advancements in the age of Industry 4.0. Here’s why:

As a maintenance supervisor, there is the burden of responsibility to ensure equipment is being properly taken care of. You must rely on a sufficiently trained maintenance crew and the right tools to monitor activities, expenses, parts, lubricants, etc. Daily task execution has an opportunity to provide education in real time. For example, inspections should be accompanied by objective questions and picture examples to coach the inspector on best practices. Meanwhile, inspection results, route compliance, lubricant consumption and more can and should be automatically tracked.

As a maintenance supervisor, there is the burden of responsibility to ensure equipment is being properly taken care of. You must rely on a sufficiently trained maintenance crew and the right tools to monitor activities, expenses, parts, lubricants, etc. Daily task execution has an opportunity to provide education in real time. For example, inspections should be accompanied by objective questions and picture examples to coach the inspector on best practices. Meanwhile, inspection results, route compliance, lubricant consumption and more can and should be automatically tracked.

As a maintenance planner, efficiently organizing work activities is important to help anticipate potential causes of delays and then plan the parts, labor and resources needed to improve productivity. This is necessary as planning lubrication activities requires complete awareness of the recurring needs of each machine, along with feedback from inspections and other condition monitoring findings to trigger on-condition tasks.

As a maintenance planner, efficiently organizing work activities is important to help anticipate potential causes of delays and then plan the parts, labor and resources needed to improve productivity. This is necessary as planning lubrication activities requires complete awareness of the recurring needs of each machine, along with feedback from inspections and other condition monitoring findings to trigger on-condition tasks.

As a maintenance scheduler, managing the recurring route activities, such as regreasing bearings with ultrasonic techniques at various intervals, can be challenging. Doing so requires tools to merge and assign routes to available personnel with various viewing formats. As routes get assigned from a dedicated lubrication platform, they should automatically be made available on the technician’s mobile device, complete with all task detail, asset data, images, procedures, etc.

As a maintenance scheduler, managing the recurring route activities, such as regreasing bearings with ultrasonic techniques at various intervals, can be challenging. Doing so requires tools to merge and assign routes to available personnel with various viewing formats. As routes get assigned from a dedicated lubrication platform, they should automatically be made available on the technician’s mobile device, complete with all task detail, asset data, images, procedures, etc.

As a reliability engineer, controlling against improper lubrication and contamination are common challenges when improving equipment reliability. A dedicated lubrication management tool will help transition current practices to best practices, including proper lubricant selection, procedures and machine modifications for contamination control, sampling, inspections, filtration and more.

As a reliability engineer, controlling against improper lubrication and contamination are common challenges when improving equipment reliability. A dedicated lubrication management tool will help transition current practices to best practices, including proper lubricant selection, procedures and machine modifications for contamination control, sampling, inspections, filtration and more.

As a lubrication technician, keeping track of lubricant type, volume and frequency of application can be overwhelming across countless lubrication points. A connected lubrication mobile application can walk you through these details on-the-fly while tracking completions, usage and inspection conditions. Moreover, as turnover occurs in the workforce, there must be a streamlined software solution to integrate historical knowledge with modern best practices.

As a lubrication technician, keeping track of lubricant type, volume and frequency of application can be overwhelming across countless lubrication points. A connected lubrication mobile application can walk you through these details on-the-fly while tracking completions, usage and inspection conditions. Moreover, as turnover occurs in the workforce, there must be a streamlined software solution to integrate historical knowledge with modern best practices.

Why Lubrication Needs a Dedicated Management Tool

Proper lubrication is critical to minimizing friction in industrial rotating equipment. Thus, it’s an essential activity in maintenance to keep lubrication in check with routine activities, such as inspections and oil changes. However, common mistakes often go unnoticed or inaccurately diagnosed, for example, when bearings are relubricated with the wrong grease or when contaminants enter an oil reservoir through an open port. These lubrication issues are like the case of the boiling frog - an apologue that places a frog in a gradually heated pot of water where, lacking any sense of danger, the amphibian will contently remain until it is boiled alive.

Proper lubrication is critical to minimizing friction in industrial rotating equipment. Thus, it’s an essential activity in maintenance to keep lubrication in check with routine activities, such as inspections and oil changes. However, common mistakes often go unnoticed or inaccurately diagnosed, for example, when bearings are relubricated with the wrong grease or when contaminants enter an oil reservoir through an open port. These lubrication issues are like the case of the boiling frog - an apologue that places a frog in a gradually heated pot of water where, lacking any sense of danger, the amphibian will contently remain until it is boiled alive.

When common lubrication issues happen, failure is often not immediate. Instead, the consequences tend to be initially silent as they slowly snowball into more significant problems without an obvious connection to the root cause. Or worse, they gradually decrease equipment productivity or increase preventive maintenance, i.e., more frequent bearing replacements or oil changes. Why is that worse? Not only are these costly, but much like the boiled frog, the lack of a sudden failure event creates complacency, downplaying urgency and negatively impacting the perceived need for action.

For a lubrication technician, the need for procedures and guidance can be more apparent for tasks such as flushing a circulating system before switching incompatible lubricants. But as mentioned, even daily activities need careful management to ensure they are done correctly. For example, it's important to consistently know which lubricant to use, how much, how often, and where to apply it, what to inspect for, and so on.

Yet, managing lubrication activities requires more than that:

- Planners and schedulers require tools to develop efficient plans and routes.

- Maintenance managers need tools to track lubricant usage and consider consolidation efforts to minimize costs and risks of cross-contamination.

- Reliability engineers need dependable data to make decisions based on lubricant condition monitoring and analyze opportunities for equipment modifications.

For a plant manager today, these key lubrication activities are essential to long-term plant operations and reliability. But without the right strategy and tools, lubrication will continue to hinder these necessary improvements.

Integrating Lubrication Management Tools into your CMMS or EAM

For many, managing maintenance activities is done with a Computerized Maintenance Management System (CMMS) software or platform. Managing the overall lifecycle of your assets is done with an Enterprise Asset Management (EAM) software. The benefits of streamlining maintenance activities or maximizing the value of your assets are essential for most industrial facilities. Yet even in 2022, some activities, like lubrication, are often subtly influenced by everyday challenges.

For many, managing maintenance activities is done with a Computerized Maintenance Management System (CMMS) software or platform. Managing the overall lifecycle of your assets is done with an Enterprise Asset Management (EAM) software. The benefits of streamlining maintenance activities or maximizing the value of your assets are essential for most industrial facilities. Yet even in 2022, some activities, like lubrication, are often subtly influenced by everyday challenges.

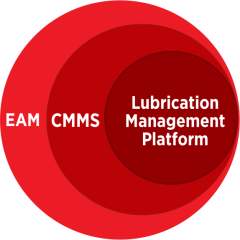

EAMs and CMMSs are often viewed with many overlapping features and intended applications. For example, many common features of a CMMS, such as managing work orders and predictive maintenance, are also features of an EAM. In general, an EAM is designed to be more holistic than a CMMS by managing assets at a higher level.

Choosing an EAM is often a decision when an organization reaches a certain personnel size or when there exists a need for a more diverse set of features. Yet, these added features usually come with a tradeoff. For example, a CMMS is often preferred for maintenance personnel who value a program designed and dedicated to more everyday maintenance objectives.

Similarly, while lubrication can be run through a CMMS, it is not designed for the unique aspects of everyday lubrication, especially when prioritizing best practice lubricant management efforts and transitioning through machine modifications to improve reliability. At various organizational levels, different software solutions become more relevant and beneficial.

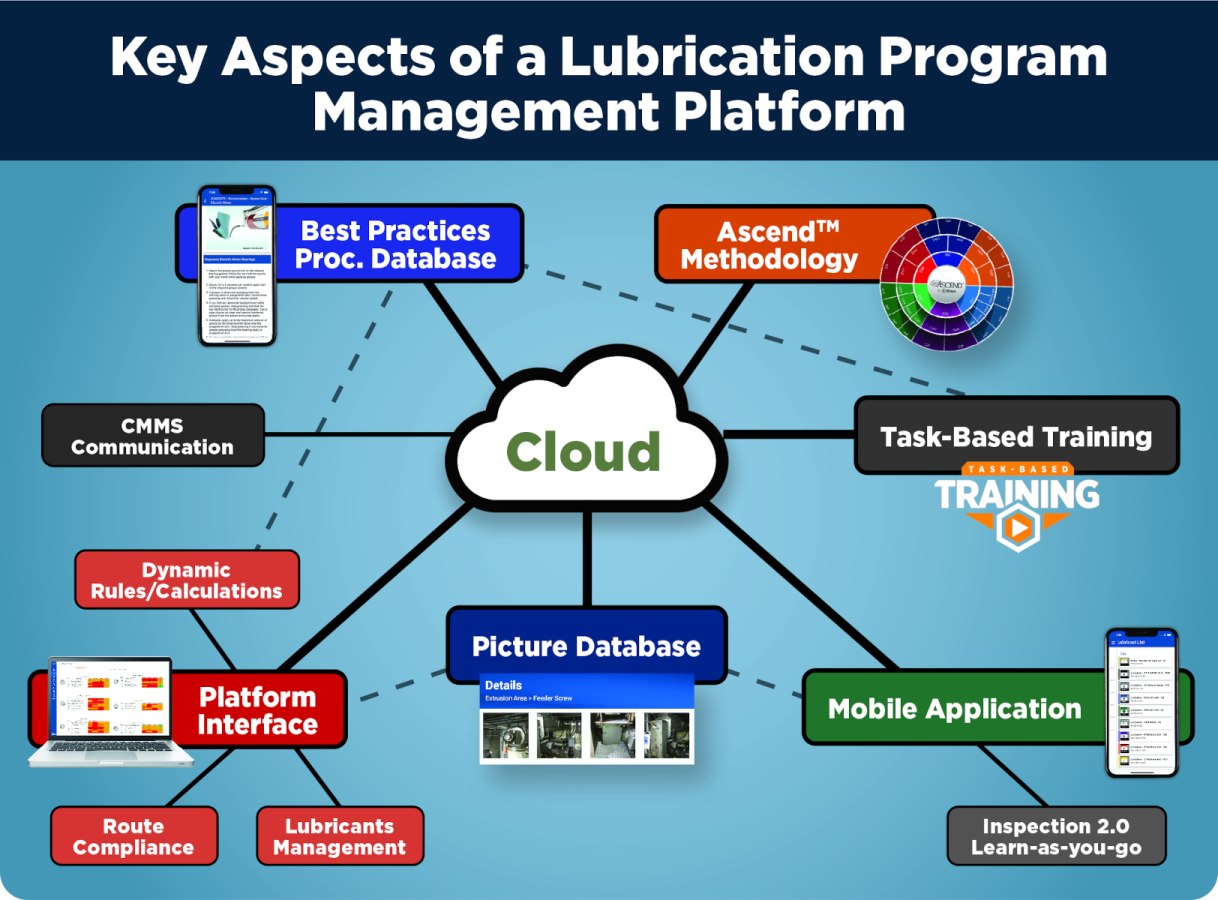

At the plant floor and maintenance management levels, a dedicated management solution targets these lubrication objectives to control contamination, minimize lubricant cross-contamination, optimize the dynamic routing of various intervals, monitor lubricant use and compliance of tasks and more. Moreover, these can then communicate the CMMS management aspects such as work order activity and inventory.

Lubrication as a Reliability Strategy

Those who have been challenged with frequent unplanned downtime due to improper lubrication find difficulty in managing lubrication as it requires ashifting the collective mindset regarding proper lubrication. When successful, countless organizations have used lubrication initiatives for decades as a winning move to reduce costs, save time and improve equipment reliability.

Maintenance teams who need a proven solution must take lubrication seriously. A central management tool is needed to help the key individuals who champion these lubrication initiatives. This includes initially identifying where the opportunities are, documenting best practices, monitoring stages of implementation and keeping overall objectives in focus.

These lubrication management solutions should be designed for everyday lubrication activities, both on the plant floor and in management. For example, take a look at the list below, overviewing the top nine benefits that save you time and money when leveraging management tools designed for lubrication. Images from LubePM are seen throughout as an example solution for lubrication management. If you are a maintenance or reliability professional, ask yourself - do you know how your lubrication program is doing? If lubrication is aimed to be part of your reliability strategy, these management tools can help keep these objectives on track. Also, for those interested in a free Ascend TM Self-Assessment to help benchmark your lubrication program, visit noria.com/free-assessment today.

A Dedicated Lubrication Management Platform - The Top Nine Benefits that Save You Time and Money

-

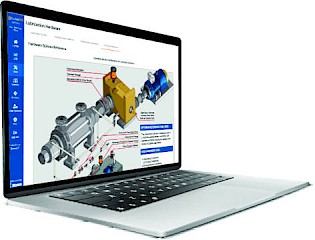

Database of Best Practice Procedures and Videos - For example, each lubrication point is assigned lubrication procedures based on industry best practices, including inspections, relubrication, filtration, lubricant drain and fill, sampling, modifications, change-outs and more. Additionally, video-based procedures enhance the learning objectives. For example, Task-Based Training videos provide training for key tasks in 15 minutes or less.

-

Dynamic Procedures - Most CMMSs only allow for static procedures that require manual edits for updates. For example, as lubricants are changed, such as for consolidation or supplier changes, the lubricant referenced in the procedure must be manually updated. A dedicated lubrication management platform should dynamically update procedures for lubricant or machine hardware changes, including text and images.

-

Mobility - Lubrication route details should be accessed and performed using a mobile application. Also, machines can be scanned, such as with a QR code, to provide guidance with route activity or quick access to pictures and data on each lubrication point.

-

Learn-as-you-go Inspection Routes - Modern machine inspection must come with a comprehensive guidance and tracking tool. For example, a mobile app walks the inspector through a detailed machine inspection, showing visual examples of what is considered normal and abnormal and specific conditions to report. Additionally, instructions are triggered for on-the-spot follow-up actions for certain abnormal conditions. All conditions are objectively tracked for data analysis, along with notes and pictures.

-

Dynamic Rules and Calculations - As a machine’s operating or environmental conditions change, so should lubrication requirements. Calculations, such as regreasing intervals, are updated as needed, and a dynamic rule structure adjusts task requirements automatically.

-

Cloud-based Accessibility and Security - All data should be connected by cloud services such as Microsoft Azure or Amazon AWS, providing a fast and reliable solution that is secure by industry standards and easily accessible from anywhere.

-

Manage and Consolidate Lubricants - As anyone who has a printed lubricant list on their wall knows, these are difficult to keep updated. Rather, lubricants should be centrally managed on a dedicated lubrication platform, designed to minimize cross-contamination and save money through integrated lubricant consolidation. A master lubricant list automatically compiles all lubricants in use, making it easy to know where each lubricant goes. Additionally, each lubrication point specifies a recommended lubricant to meet reliability objectives. As lubricants are changed over in machines, the lubricant list and any lubricant references are automatically updated. Along with the lubricant brand, each lubricant has a unique code and label that shows up anywhere the lubricant is referenced to minimize chances of cross-contamination.

-

Lubrication Implementation Manager - Changing lubricants or modifying machines for lubrication best practices can take time, often months or years. With a lubrication management platform, these changes follow a user-dependent approval process, and implementation tracking dashboards are monitored while completion stages take place. Meanwhile, reoccurring tasks are dynamically revised as lubrication points are updated in real-time.

-

Ascend Guidance for Lubrication Excellence - As with any reliability initiative, a lubrication program should be guided by industry best practices. The Ascend™ Chart, for example, is a holistic methodology for assessing the current state of lubrication against world-class standards. The lubrication management platform should provide guidance as metrics are visualized to simulate the progress of lubrication best practices using the AscendTM Chart. This helps prioritize lubrication efforts throughout all stages of lubrication program development, particularly early on.