Dispersancy Testing

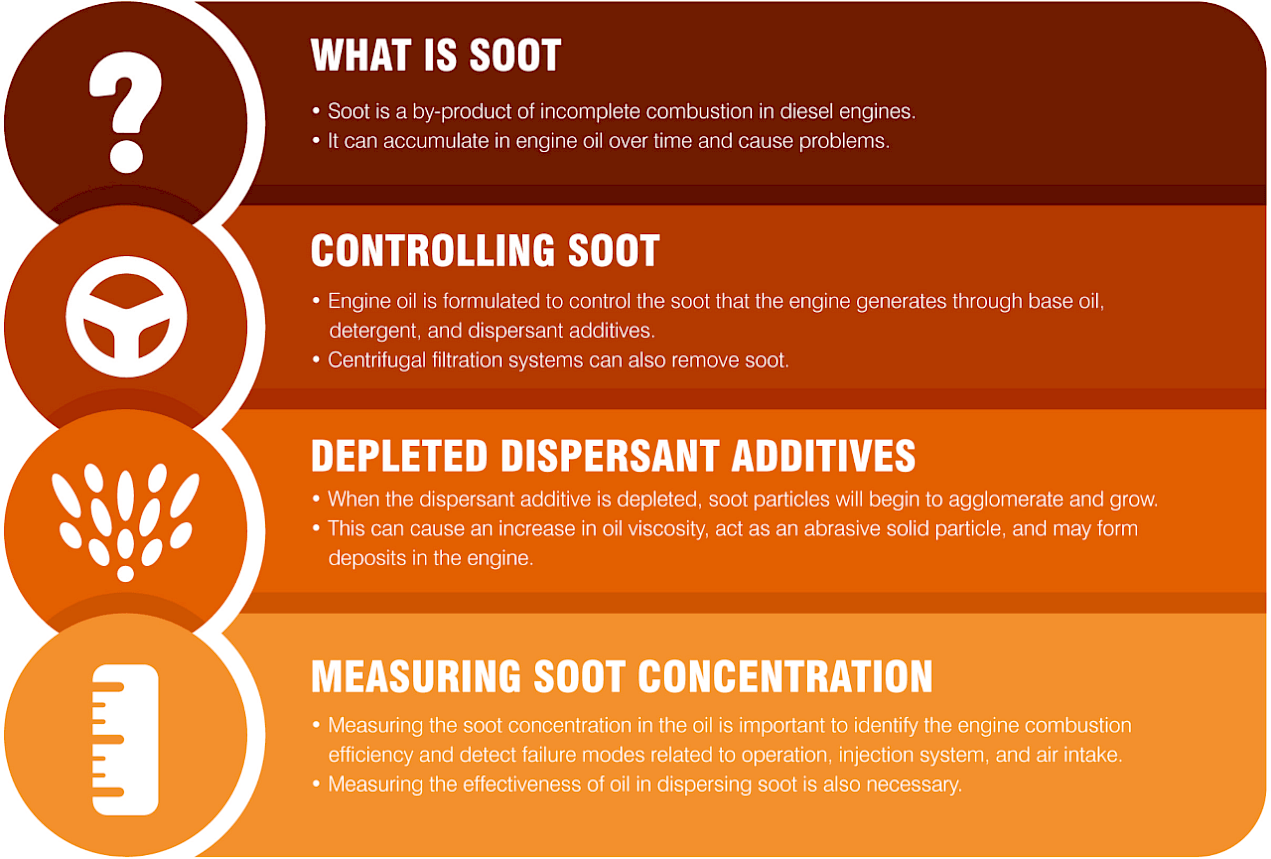

Soot is the by-product of incomplete combustion in diesel engines and, as I see it, one of the least understood in oil analysis. Soot can accumulate in the engine oil over time and is one of the reasons why oil needs to be changed. When the levels of soot in the oil become too high, it can cause a range of problems, including wear, depletion of additives, and deposits.

Soot is the by-product of incomplete combustion in diesel engines and, as I see it, one of the least understood in oil analysis. Soot can accumulate in the engine oil over time and is one of the reasons why oil needs to be changed. When the levels of soot in the oil become too high, it can cause a range of problems, including wear, depletion of additives, and deposits.

Although injection systems have significantly improved in modern engines to maximize the fuel's heat output, and blends with biodiesel are used to reduce the generation of particulate matter, exhaust gas recirculation systems that produce more soot in the engine have also been incorporated. Soot has always existed — it's just more prevalent now.

Engine oil is formulated to control the soot that the engine generates through the base oil, detergent, and dispersant additives. Engines can also incorporate centrifugal filtration systems that can remove soot.

When an engine generates soot, the additive disperses it through spherical stabilization based on the principle of polarity (attraction between polar compounds) between the soot particle and the polar compound of the additive. The additive has an oil-soluble section, and in this way, it remains in suspension in the oil. By surrounding the soot particle with dispersant additives, its polarity is deactivated, preventing the soot particles from agglomerating and keeping them at a size between 0.02 and 0.2 µm. With increasing operation hours, the dispersant additive may become depleted if the amount of soot generated in combustion is too high or due to overextended oil change intervals.

When the dispersant additive is depleted, the soot will begin to agglomerate and grow, forming clusters of 2µm or larger. These agglomerated soot particles will cause an increase in oil viscosity, act as an abrasive solid particle, and may form deposits in the engine. Studies on the effect of oil contaminated with soot on engine wear indicate that an excess of soot can interact negatively with anti-wear additives or compete with them for metal surfaces, decreasing their protection. This has a greater impact on those areas and components that work with limit and mixed lubrication regimes.

When the dispersant additive is depleted, the soot will begin to agglomerate and grow, forming clusters of 2µm or larger. These agglomerated soot particles will cause an increase in oil viscosity, act as an abrasive solid particle, and may form deposits in the engine. Studies on the effect of oil contaminated with soot on engine wear indicate that an excess of soot can interact negatively with anti-wear additives or compete with them for metal surfaces, decreasing their protection. This has a greater impact on those areas and components that work with limit and mixed lubrication regimes.

When evaluating fleet performance or seeking to extend oil change intervals, very few consider the lubricant's ability to disperse soot loads and usually rely on the correlation of viscosity increase with soot concentration in the oil. This correlation, although correct, could be a signal that is too late when it comes to finding the optimal oil change time and the reliability of the engine. An increase in viscosity caused by soot means that it is already too late to change the oil. Viscosity increases when the dispersant has been depleted, and now the soot is agglomerated and deposited on the engine surfaces. A simple oil change will not be able to remove that soot, and the new oil charge will see its ability to protect the engine diminished.

Measuring the soot concentration is very important as it allows for identifying the engine combustion efficiency and detecting failure modes related to operation, injection system, and air intake. Changes in the soot formation trends should be investigated to prevent major problems. However, measuring the soot concentration in the oil is not enough when it comes to increasing the reliability of these engines — it is also necessary to measure the soot dispersancy.

To measure the effectiveness of oil in dispersing soot, the ASTM D7899-19 standard "Standard Test Method for Measuring the Merit of Dispersancy of In-Service Engine Oils with Blotter Spot Method" is the most accurate method. Unlike the traditional blotter spot test, which depends on the visual interpretation of a specialist and is subjective, this method defines a standard method of blotter preparation to ensure consistency and uses a charged coupled device (CCD) to take a photograph of the drop and analyse it pixel by pixel to measure different parameters such as how far the drop travels on the paper, the size of the drop centre, and the homogeneity ratio of the drop's opacity compared to a theoretical reference pattern of 32mm in diameter.

To qualify the dispersancy condition of the oil, the method defines seven observation zones that allow identifying the amount and type of contaminants in the oil. Due to the physical phenomenon of lamination, particles of the same size will be deposited on the paper in concentric zones. The compounds of larger size and weight will be in the zone closest to the centre, while the medium-sized and small particles, along with oxidation products, will be in the following zones; at the outermost end, a transparent halo may form, corresponding to the base oil. The distribution of particles in the different zones determines the dispersancy condition of the oil.

The more contaminant particles the oil has, the darker the drop will be, and the larger the diameter of the drop, the better the oil's dispersancy. When dispersancy fails, the soot particles will be agglomerated and will not travel with the base oil, showing a small, pasty black centre and a large, transparent outer halo.

The type of paper is as important as the amount of oil when preparing the drop. The method specifies a drop of 20µl of oil on the paper must be placed in an oven at 80 C (176 F) for one hour to facilitate the formation of the drop, which must be inspected within the next 60 minutes, as the drop may continue to grow.

The test apparatus (AD Systems DT 100 DL Dispersancy Tester) calculates the diameter and Contamination Index (CI) by measuring the grayscale of each pixel in the droplet and dividing by the total number of pixels. The software then calculates the Dispersancy Merit (MD) by measuring the homogeneity and distribution of the droplet opacity and comparing it to an ideal reference of 32mm.

The most important result is the Dispersancy Merit (MD) value, which indicates the oil's ability to suspend soot and is expressed as a number from 0 to 100. (MD = 0; poor dispersion: the contaminants are all concentrated in the centre of the oil spot in the test; the soot is agglomerated. MD = 100; excellent dispersion: the distribution of the soot on the filter paper is homogeneous). Additionally, the Contamination Index (CI) can be considered, which is the concentration of insoluble soot in the diesel engine oil and is expressed as a weight percentage and can range from 0% to 4.8%. Weighted Demerits can also be calculated using the following formula: DP=(100-MD) *CI.

In the coming years, we will see more and more fleets looking to extend their oil change intervals to reduce their carbon footprint. The dispersancy test will be essential in achieving this objective for a reliable engine.

References:

- Get ready for more soot in engine oil – Drew Troyer https://www.machinerylubrication.com/Read/51/soot-oil-engine

- ASTM D7899 “Standard Test Method for Measuring the Merit of Dispersancy of In-Service Engine Oils with Blotter Spot Method”

- DT 10 and DT 100DL—Dispersancy Tester - AD Systems http://www.adsystems-sa.com .

- New Method for evaluating lubricant dispersancy https://www.machinerylubrication.com/Read/29353/evaluating-lubricant-dispersancy