Using the Ascend Chart as Your Roadmap to Proactive Maintenance

Giving a broken machine a fresh new lease on life is the calling of troubleshooters and mechanics. The maintenance field attracts people who are driven by such native desires, not unlike nurses and doctors. Some people like fixing things. I'm one of those people.

Giving a broken machine a fresh new lease on life is the calling of troubleshooters and mechanics. The maintenance field attracts people who are driven by such native desires, not unlike nurses and doctors. Some people like fixing things. I'm one of those people.

Yet, today's reliability-conscious world is changing the maintenance persona, taking it in a direction away from the macho image of the past. It's no longer desirable to yearn for the meltdown or the perfect storm.

Fading, too, is the sense of pride that came with going into battle, wrench in hand, to press the limits of one's mechanical prowess. Perhaps a sad reality to some, but reality, nonetheless.

At the bottom is the basal need to aspire to reliability. This includes buying machines that are designed and manufactured for long, sustainable life. No lifecycle weak links.

Next comes precision installation and precision maintenance. This covers wide-ranging subjects such as consistency, accuracy, fit and tolerance, alignment, balance, lubrication excellence, and the correct use of fasteners.

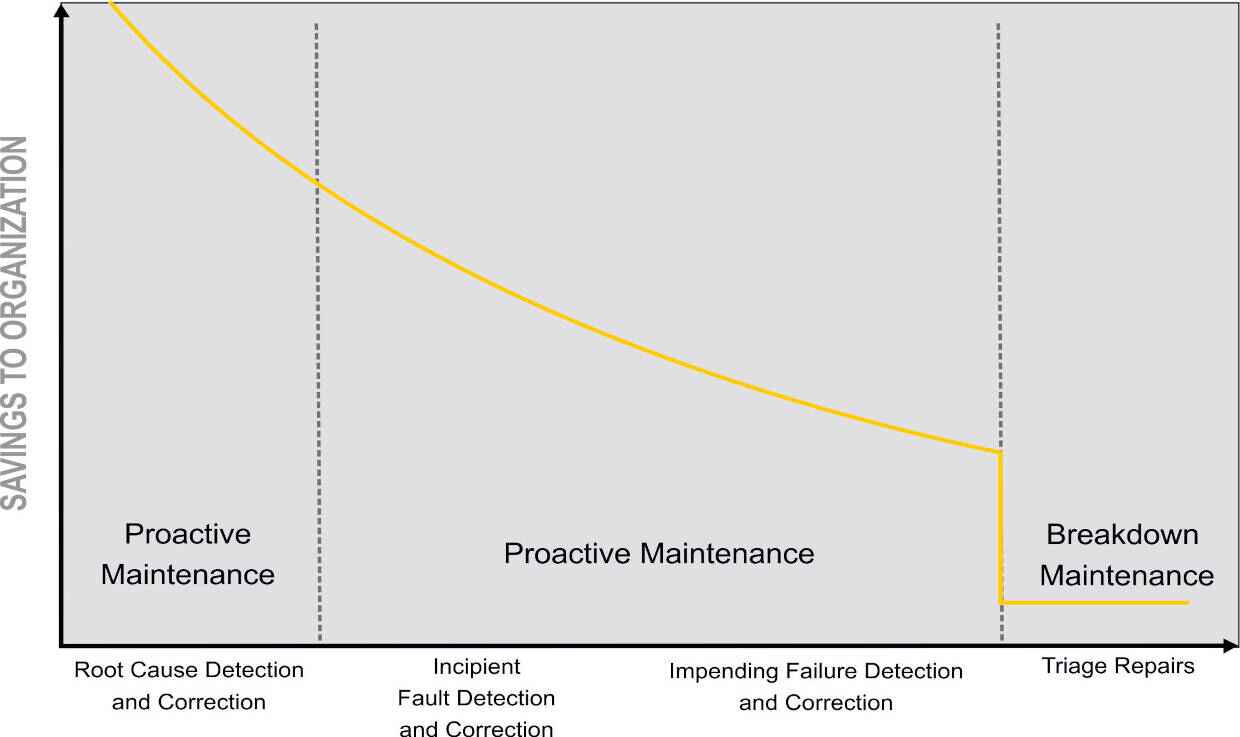

In contrast, reactive maintenance responds to any stage of machine failure along the P-F interval (incipient, impending, or precipitous). Of course, early detection (long P-F intervals) is the most desirable and is the mantra of predictive maintenance.

But why wait for the onset of failure? It's like waiting for the onset of heart disease and cancer. There may be a cure, but, in many cases, the harm is already done, or the point of detection is too late, sometimes resulting the dreaded sudden death.

When things start going south, the faster and faster they seem to go as they continue to get worse. This is obviously a place where no one wants to be.

So, in effect, reliability is, by definition, aspirational. For humans, aspiring toward good health often involves acute and often-times uncomfortable lifestyle changes — you know, all the fun that comes with changing bad habits.

Proactive Maintenance is Misunderstood

I first started writing about the virtues of proactive maintenance in the 1980s. Preventive maintenance and predictive maintenance were also important but failed to underscore the value of aspirational-driving machine reliability.

Proactive maintenance is about change and control. It has a condition-monitoring component, but only as part of the overall proactive maintenance philosophy.

| Maintenance Strategy | Action Required | RCM-Based Application |

|---|---|---|

| Run to failure/breakdown (reactive) | Repair or replace upon failure. | Noncritical. Costs to control or detect failure exceed benefits. |

| Preventive Maintenance (scheduled part replacements) | Repair or replace on time or in cycles. | Asset has a well-documented mean time between failures (MTBF) and a small standard deviation. |

| Predictive Maintenance (on-condition maintenance) | Employs condition monitoring to detect early-stage failures. Replacement or repair is scheduled on condition. |

Asset fails randomly. Critical nature justifies early detection techniques. |

| Proactive Maintenance | Advanced eradication and control of known root causes (e.g., misalignment, unbalance, lubricant starvation, lubricant contamination, etc.) Condition monitoring detects the presence of failure root causes. |

Objective is to reduce the failure rate for a given time period. |

Proactive maintenance refers to machine lifestyle changes that avoid (or eradicate) the underlying conditions that lead to machine failure (faults, abnormal wear, etc.). Proactive maintenance targets root causes, not symptoms, and the central theme of which is to extend the life of mechanical machinery as opposed to making repairs.

Proactive maintenance certainly doesn't foster the belief that failure is normal or can be expected.

Table 1 above compares and contrasts the difference in maintenance philosophies. The graph below it plots the cost savings and benefits to organizations.

Three Simple Steps

Proactive maintenance is a mindset change. What I'm really talking about are the "'ers" of lubrication and maintenance. Sadly, these are not generally understood and even less well-applied.

For instance, we are seeking oil that is not just clean but cleaner, and oil that is not just dry but drier. We can keep going… cooler, better lubricant, better inspection practices, better maintenance practices, better relubrication intervals, etc.

You get it — the 'ers of lubrication and maintenance. This may sound simple to you, but why does it seem like many organizations aren't doing it?

For example, how do you get a hydraulic pump to last four-times longer? How do you double the rebuild interval of a diesel engine? How do you reduce bearing-replacement frequency by 80%? How do you reduce unscheduled downtime by 50%?

All these objectives require change, persistence, and control. Proactive machine-lifestyle changes are designed to do just that.

It all boils down to these three simple steps:

- Set your target for change. The target must be measurable or verifiable, and preferably better than past practices or conditions. You're not doing proactive maintenance if your oils are not cleaner, cooler, drier, etc. Just okay is not good enough. Machine life will not be extended for "okay".

- Next, you must implement change that attains the targeted machine-lifestyle change. You may say you're going to lose 25 pounds, reduce your blood pressure and get your cholesterol under control. But you are lying to yourself if you don't change the root causes. I assume that you know what I mean. For your machine we're talking about changes like better filtration, better lubricants, better inspection skills, better procedures, better training. If you've set a target cleanliness of ISO 16/13/9 from historic averages of 19/16/11, then the changes might include better seals, better breathers, better lubricant handling/storage practices, and better contamination control.

- This third step is critical. You must measure to verify the targets are being achieved and controlled. Celebrate successes, resolve deficiencies. If it is important enough to set a target and implement changes, it is important enough to measure.

What gets measured gets done. Oil analysis can tell us about oil health, cleanliness, and dryness. Inspection can tell us about oil levels and leakage, contaminant exclusion, oil temperature, aeration, etc.

Machinery Lubrication has published dozens, perhaps hundreds, of real-world examples of how these three simple steps work rigorously followed. It's not an imaginary or an abstract theoretical concept. To better understand the magnitude of proactive maintenance, I strongly encourage you to read this article: The Power of 10X.

Follow the Ascend Chart

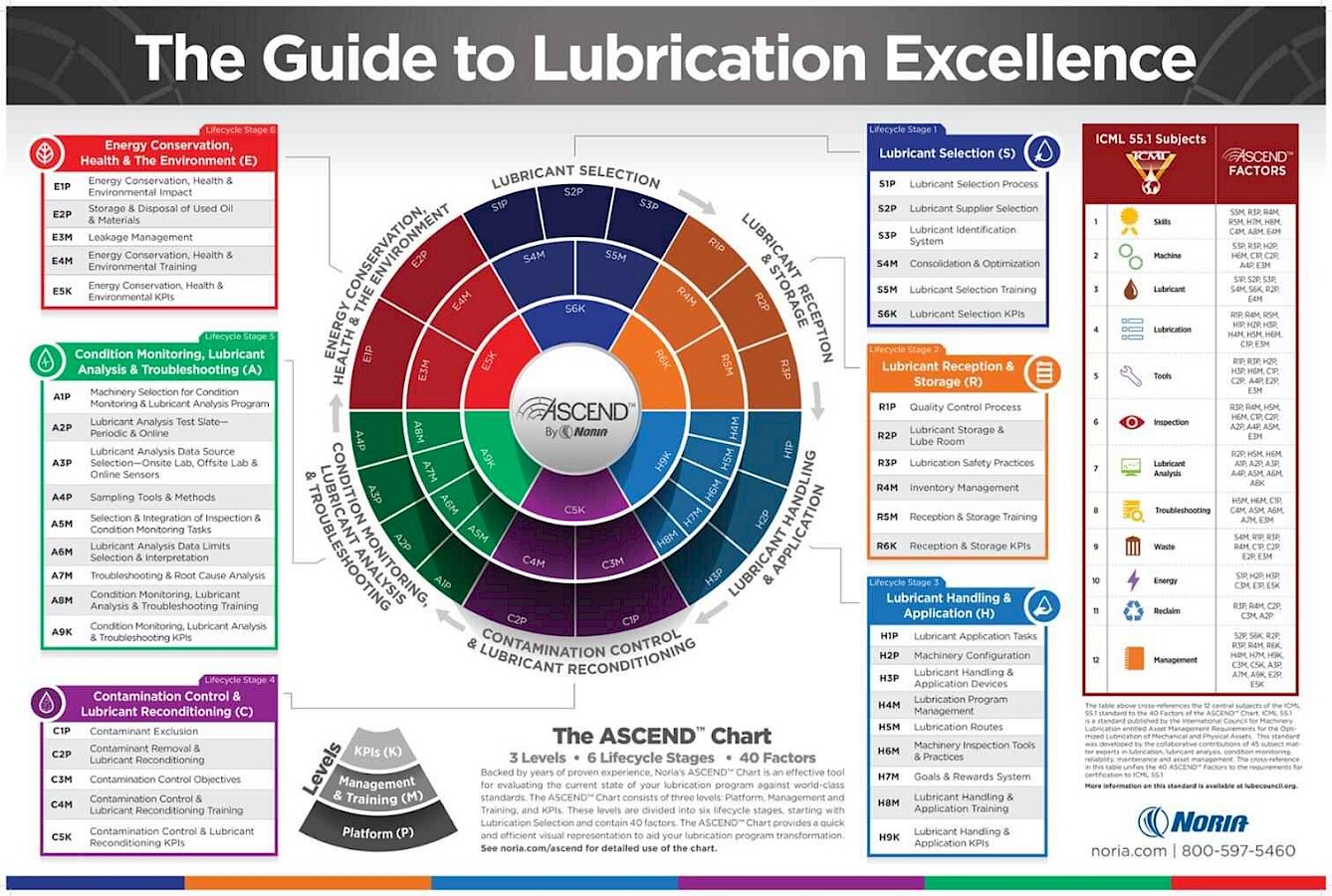

The Ascend Chart was constructed to provide a useful framework or roadmap for the deployment of a proactive maintenance strategy in lubrication. It consists of six lifecycle stages, going clockwise starting from the top. Within each stage are specific "change and control" opportunities.

The following are some examples:

- Lubricant Selection: Matching the correct lubricant to your machine, operating environment and exposures is an engineering exercise. Don't let anyone suggest otherwise. Lubricants are not all alike. There are tens of thousands to choose from. What is the perfect viscosity, viscosity index, base oil type, additive chemistry, treat rate, package and transport method, supplier support, etc.? Get the help you need.

- Lubricant Reception and Storage: This refers to your lubricant's health and protection from contamination and accidental mixing. A lubricant can lose more life during reception and storage than when it resides in the machine.

- Lubricant Handling and Application: This covers how lubricants are changed or relubricated, the frequency and the amount. Mostly it seeks to ensure that machines aren't under-lubricated or over-lubricated. Changing oil and grease levels, even by what seems like insignificant amounts, can have a sharp impact on machine life. Next, change the oil on time. Through routine oil analysis oil, changes can be changed "on condition," not too soon or too late. This can be applied to regreasing intervals as well.

- Contamination Control and Lubricant Relubrication: Just as the name implies, keeping lubricants clean, dry, and cool within the target level is an endless but necessary task. Controlling contaminant ingress is job one. Next is the rapid removal of contaminants once that make contact with the oil. Just because the oil looks clean and dry doesn't make it so. Use oil analysis for verification.

- Condition Monitoring, Lubricant Analysis & Troubleshooting: It's darn hard for a machine to be in trouble (impending failure of bearing, gear, cylinder, engine, etc.) without the lubricant knowing about it first. The lubricant is the common medium across all frictional components. Oil analysis only works when lubricants are sampled frequently, sampled properly, and tested correctly. Don't pretend to save money by buying cheap oil analysis. The same holds true for inspection. Inspectors shouldn't just be just looking at machines but should, instead, be carefully examining the machines with a keen and purposeful eye. This is just as important as oil analysis but is rarely done well.

- Energy Conservation: Health & the Environment. Energy conservation alone presents huge cost savings opportunities for most organizations. Much of this relates to lubricant selection, as well as established lubrication practices too. Reducing machine frictional losses by 10-20% has often been reported by making smart choices.

Point of Diminishing Return

I often refer to the need to optimize and not maximize. We're not trying to maximize reliability, but rather to optimize it. An excellent discussion of this can be found in the article, How to Optimize the State of Lubrication.

Excessiveness is a source of waste and an unwise use of time and resources. Yes, the cost of excessive training, cleanliness, dryness, oil sampling frequency, test-slate selection, lubricant robustness, relubrication frequency, etc., can, in certain cases, exceed the benefits gained. But don't let the fear of "excessiveness" deter you from the pursuit of the optimum.