DO’s and DON’Ts of Setting Contamination Control Objectives

It is pretty well understood, or at least widely stated, that what gets measured gets done. So it should come as no surprise that contamination control objectives should be implemented; they are our means of measuring the effectiveness of our equipment re-lubrication processes, not to mention how many of our other contamination control measures are going. When we set these objectives, though, we need to keep a few things in mind: consider this, the Dos and Don'ts of setting contamination control objectives.

It is pretty well understood, or at least widely stated, that what gets measured gets done. So it should come as no surprise that contamination control objectives should be implemented; they are our means of measuring the effectiveness of our equipment re-lubrication processes, not to mention how many of our other contamination control measures are going. When we set these objectives, though, we need to keep a few things in mind: consider this, the Dos and Don'ts of setting contamination control objectives.

DO

Do set measurable and achievable goals.

Having solid goals that you can actually hit makes a huge difference, not just for the equipment, but also for the entire reliability team. How frustrating would it be to have a goal that can never be achieved? Look at your process, operating conditions, lubricant demands, machine demands and criticality, and see what makes sense for your capabilities and reliability goals. “Pie in the sky” dreams are great, but we live in the real world, and we need real goals.

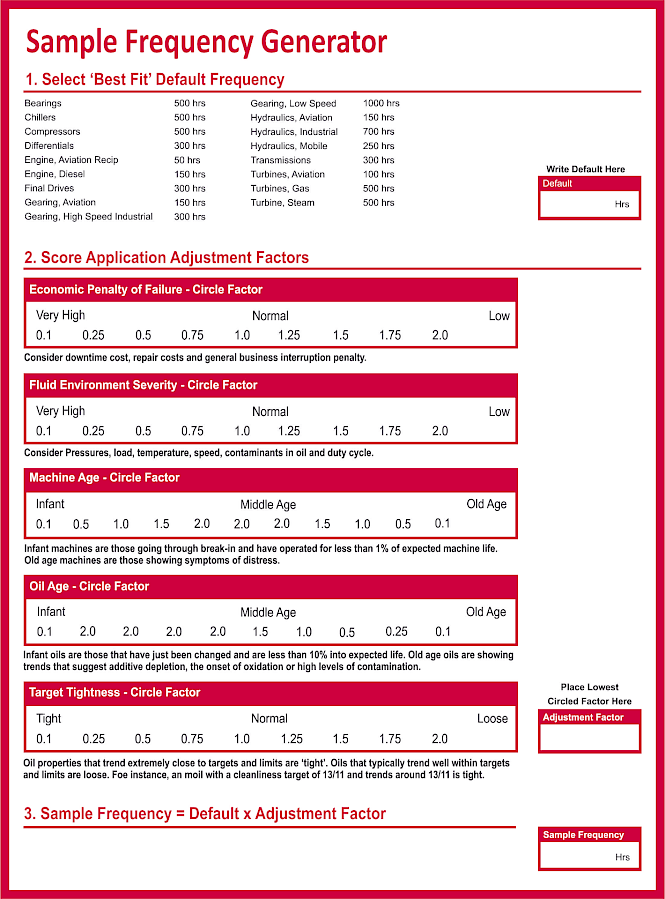

Figure 1: Sample Frequency Generator

DON'T

Don’t set a blanket statement and make it “the goal.”

We can’t just say, “I want clean oil in all of our equipment,” and call it a day. We can’t measure this in any meaningful way, and we don’t even have a definition of “clean” to shoot for. ISO cleanliness codes are a simple way to start on this.

DO

Do create a standard for how we are going to go about reaching the goals.

We need to have a set way of accomplishing something, and we need to all be on the same page (for both processes and procedures). When we are all doing these procedures, whether it is re-greasing a bearing or topping off a gearbox, we remove variables that will mess with the data that we are using to track our progress.

DON'T

Don’t set standards and then forget about them.

If we have created standards, whether procedures or targets for oil cleanliness, we should have done so with a specific goal in mind, right? So why would we set those things and then just let people completely forget about them? The standards should become a part of our everyday lives, integrated into how we complete tasks and do our jobs in general.

DO

Do modify your equipment and review your tools.

Machine modification can be a daunting task, but it doesn’t have to be. Look at your reliability goals for that piece of equipment. Look at the aspects that might prevent you from reaching those goals, i.e.:

Does this machine need to breathe? Does it have clean and dry air to breathe? What do I need to do to make sure that it does have clean and dry air to breathe?

Are there tight targets for cleanliness? Do I have a way of getting clean oil into the machine? Would something like hydraulic quick connects help prevent unwanted contaminants from entering my machine?

Is this machine susceptible to water contamination? How is water/moisture getting into my machine? Am I using lip seals where I should be using labyrinth seals? Are there any early warning indicators, like bottom sediment and water bowls, or even moisture sensors, that can be installed?

DON'T

Don’t buy every sensor on the planet and put it on your machine.

Sensors, quick connects, and desiccant breathers are great tools, but not every piece of equipment warrants the investment. A non-critical piece of equipment may be more efficient if left to die on its own, versus using every piece of technology available to extend its life.

There is no magic bullet when it comes to setting cleanliness targets or reliability goals for your facility, but doing proper contamination control doesn’t have to be some daunting task. The first task should be to figure out your reliability goals for any given piece of equipment. Once that is figured out, you need to determine what cleanliness target will help you reach those goals. Here is a great calculator to help you out with cleanliness and dryness targets (remember, moisture is the second most damaging contaminant to your oil and machine).

Great! Now that we know how clean and dry we need to get our oil, how often do we actually sample it to make sure we are hitting our targets? We made a calculator (Figure 1) for that too!

Now, using these two calculators in tandem, along with your overall criticality, you should be able to easily determine what sensors or modifications should be performed to help you achieve your goals. If you are still having issues, or have questions about criticality and how to calculate that, send us a message, we will be happy to talk you through it (we might even have some tools available for that, too).