How to Quantify Severity of Wear and Contamination with a Filtergram

This article reports diesel engine oil analysis data, demonstrating the use of filtergram x-ray fluorescence to quantify severity of wear and contamination. Two independent measurements were performed on each filtergram specimen: pore blockage particle count and x-ray fluorescence (XRF) large particle elemental analysis. Causal inflections in ASTM D7720 cumulative distributions indicate severity thresholds for filtergram XRF elemental analyses.

What Can You Expect to Learn?

- Filtergram particle quantifier (FPQ) measures particle count and ISO code for particulate debris accumulated on a > 4-micron filtergram.

- X-ray fluorescence (FPQ XRF) reports elemental analysis of the particulate debris on each filtergram specimen.

- Wear and contamination severity determination requires analysis of greater than 4-micron debris including Fe, Cr, Ni, Cu, Sn, Pb, Al, and Si, in addition to particle count.

- Filtergram specimens retain wear debris if needed for future reference, defect elimination and root cause failure analysis (RFCA).

Introduction

This presentation demonstrates the use of ASTM D8127 Filtergram X-ray Fluorescence to quantify abnormal wear originating from iron alloys, white metal alloys, and yellow metal alloys in a population of 52 in-service diesel engine oil samples. These in-service oil samples were tested with a pore-blockage particle counting process extracts, and retains particulate matter larger than 4-microns on the filtergram specimen. Each filtergram is nondestructively tested with energy dispersive x-ray fluorescence (XRF) to measure elemental composition including iron (Fe), chromium (Cr), nickel (Ni), copper (Cu), lead (Pb), and tin (Sn) to quantify abnormal wear from hundreds of moving engine components in every engine oil sample.

Worldwide engine oil analysis extensively focuses on optical emission spectroscopy (OES) to measure Fe,Cr, Ni, Cu, Pb, Sn and Si to quantify abnormal wear and contamination. However, the molecular to ultra-fine particle size limitation for OES obscures its effectiveness for distinguishing abnormal component wear and engine-oil dust contamination for the following: 1) there are numerous molecular-to-micron sizes that range as normal or benign sources of these seven elements, and 2) severe wear and dust contamination debris are typically larger than the OES particulate measurement range.

OES measurement range detects all seven of these elements in engine oil originating from many sources. For example, “rising copper concentration can reach well over 300 ppm".

As alarming as this sounds, it has been reported that copper sulfide, even in these high concentrations, is generally benign and, as such, may not be associated with (cause or effect) cooler failure, accelerated wear or lubricant oxidation. Copper found in diesel engine oils can come from wide-ranging sources and can exist in the oil in varying states.

From the oil analyst’s perspective, determining the source, nature and state of copper is essential to correctly interpreting the alarm, in terms of engine reliability and the appropriate response. Although very valuable, [OES] elemental analysis has only limited capability and, in fact, may produce false alarms or mask real alarms unless other tests are performed concurrently or on an exception basis.”

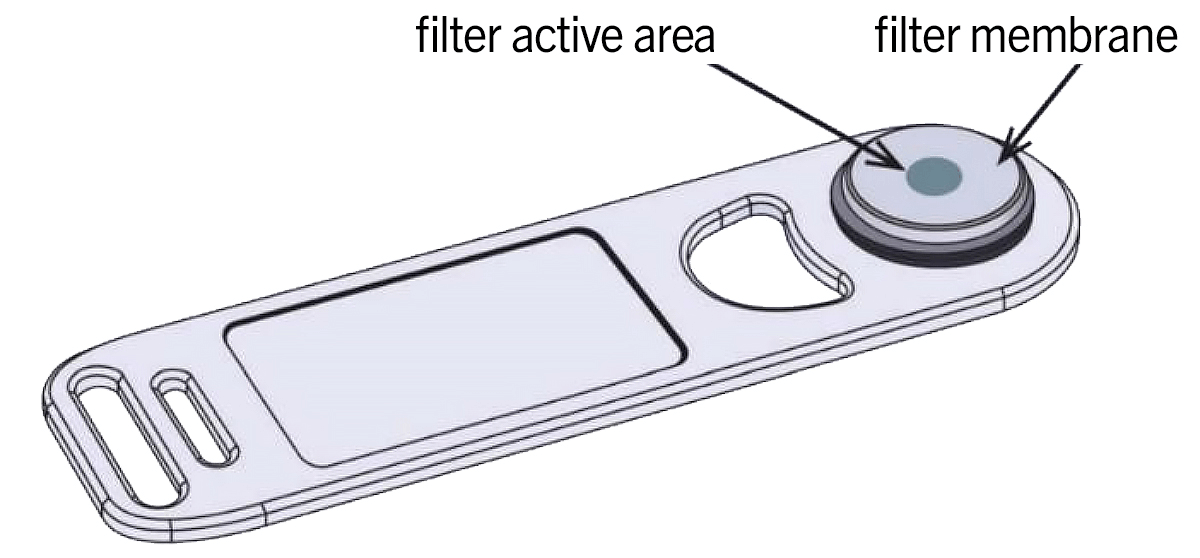

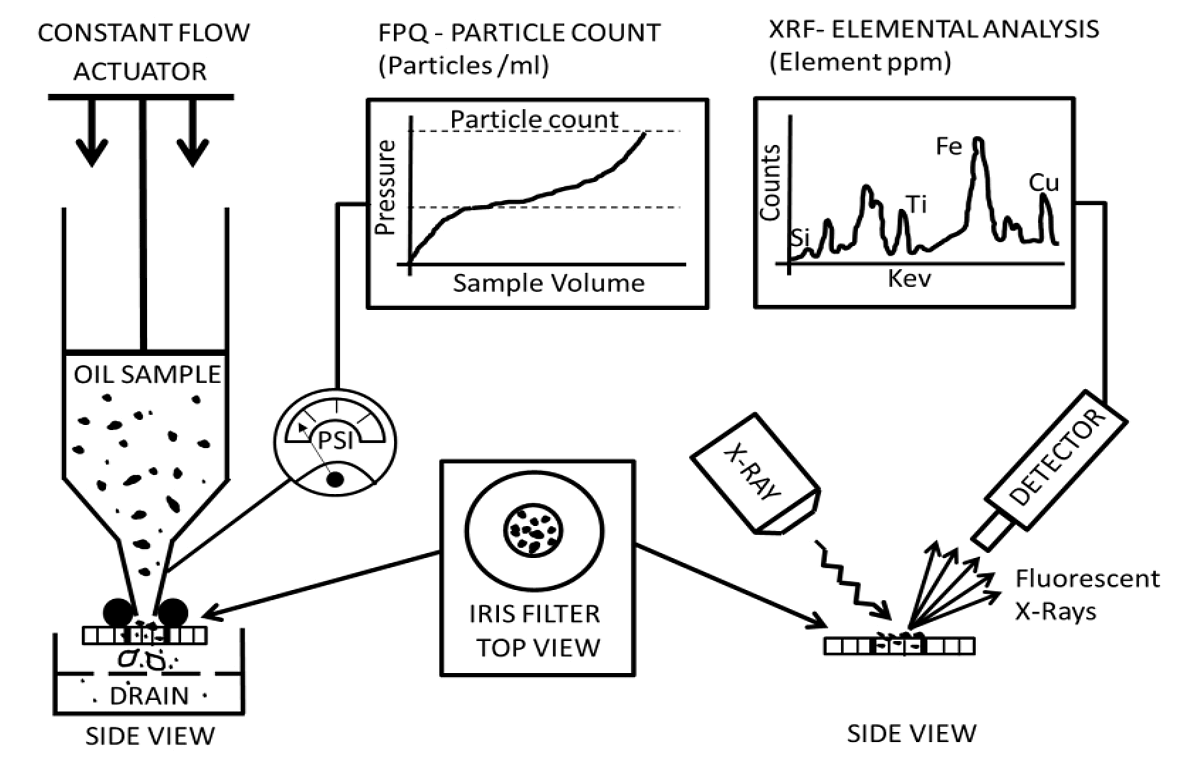

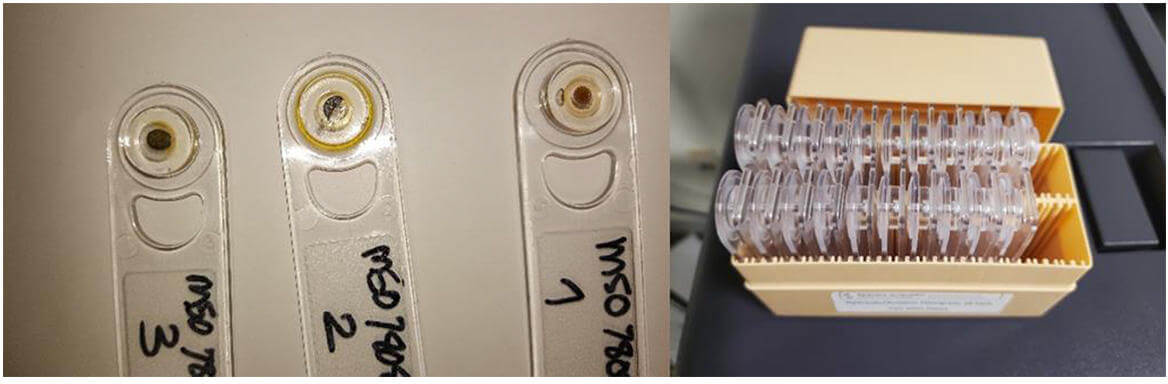

The filtergram particle quantifier with X-ray fluorescence (FPQ XRF) performs pore blockage particle counting, followed by energy dispersive X-ray fluorescence multielemental analysis, per ASTM D7684, ASTM D8127 and ISO 21018-3. Figures 1 and 2 show the filtergram particle quantifier (FPQ) as having an active area on the 4-micron filter membrane where wear debris accumulates. The FPQ specimen is labeled, XRF elemental analysis is performed, and the specimen is retained for visual and microscopic examination.

Figure 3 outlines the two-step process for extracting >4 micron particulate from in-service oil samples and measure the elemental composition of debris deposited onto the filter active area.

Advantages for this 2-step process include:

Fast solvent-free method:

- No dilution or acid digestion sample preparation.

- Suitable for field conditions.

- Repeatable, consistent, particle presentation with measured volume for PPM concentration calculation.

Powerful data for advanced wear detection:

- Particle count measurement result.

- Non-destructive XRF test reports 16 elements (PPM): Fe, Ag, Al, Cr, Cu, Ni, Pb, Si, Sn, Ti, Mo, Co, Mg, W, V & Zn.

- Specimen with debris available for future investigation.

- Correlates with other large particle techniques.

Severe Wear Debris

Severe sliding, rolling fatigue, and bending fatigue are failure mechanisms that exponentially shorten functional life of machine components. Damage from each mechanism is cumulative and progressive.

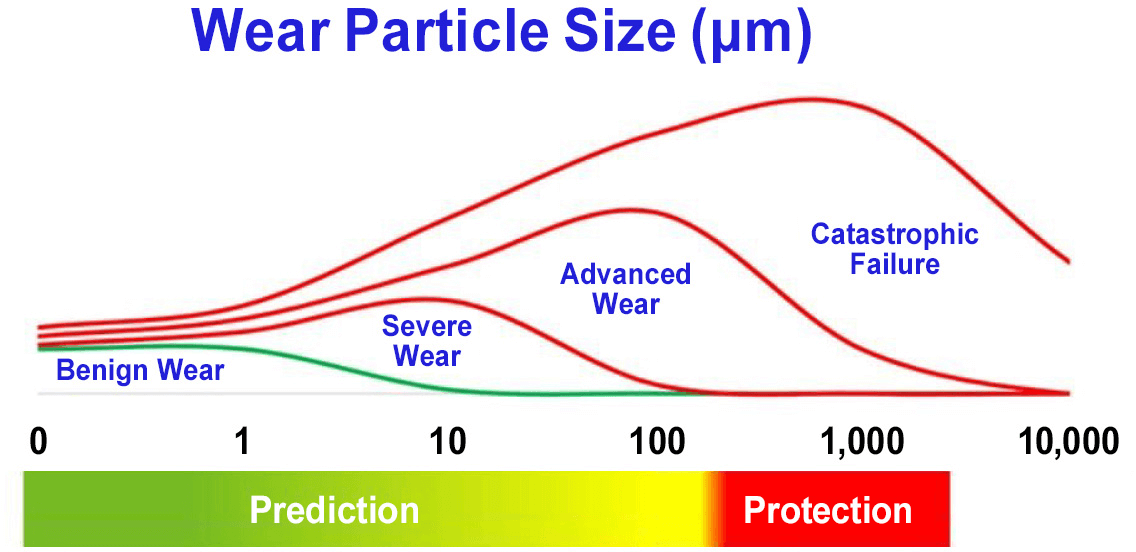

Wear debris from each of these mechanisms carries evidence about the damaged component, the insults causing damage, and the stage or severity of failure progression. Benign wear severe, advanced, and catastrophic wear presented in Figure 4, represent increasing severity levels.

Abnormal abrasion, adhesion, and fatigue (Figure 5) are large wear particles in base metals, not just oxides.

- Microspall particles range between 10 mm and 50 mm.

- Laminar particles and chunks range from 50 mm to several hundreds of microns.

- Optical emission spectroscopy is blind to large particles.

Filtergram particle quantifier (FPQ) measures particle count and ISO code for solid particulate debris accumulated on a > 4-micron filtergram. This includes the important stages of severe wear and advanced wear that lead to catastrophic failure wear-debris, with size ranges shown on Figure 4. Notice that the range for prediction of impending catastrophic failure requires measuring wear debris in the OES blindspot range from 4-micron to 2-millimeter size range.

Severity Limits for FPQ XRF and OES Data

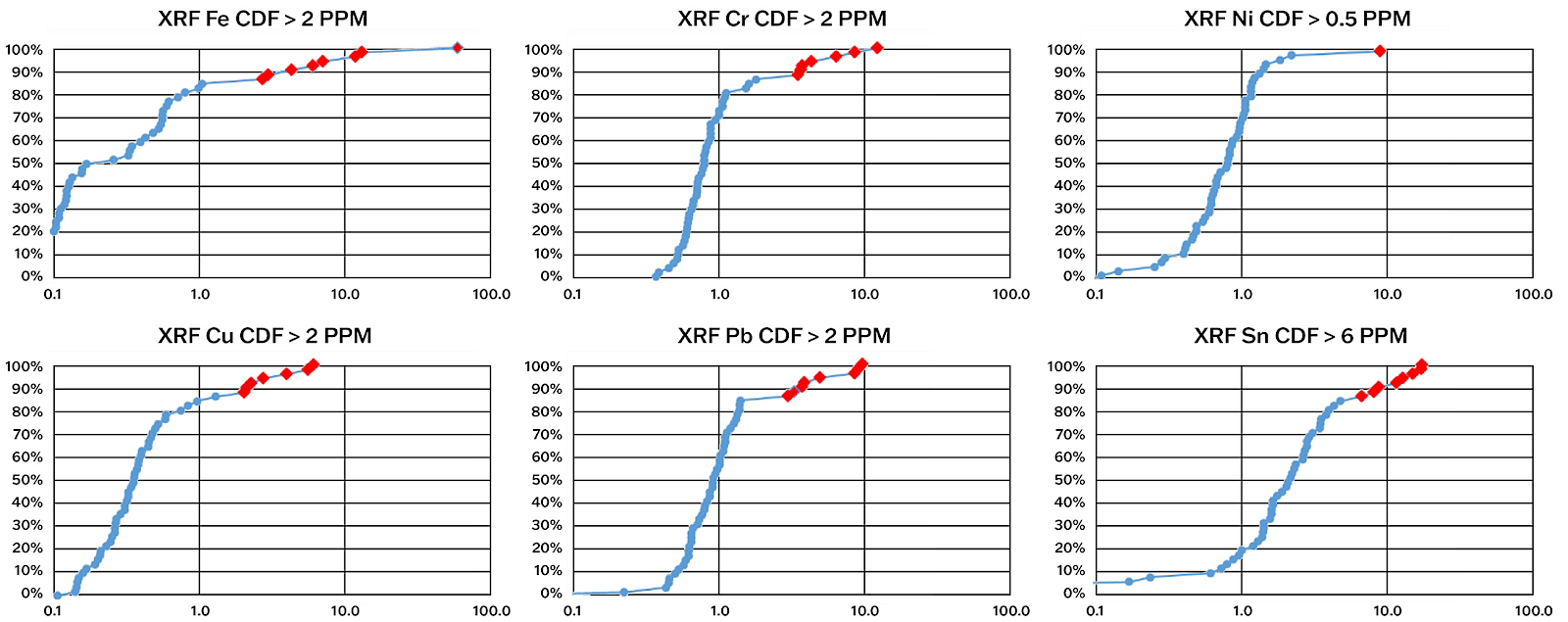

A population of 52 in-service engine oil samples were tested with filtergram XRF and also with OES. ASTM D7720 cumulative distributions shown in Figure 6 were used to select preliminary severity limits. Preliminary XRF severity limits for Fe, Cr, and Ni quantify abnormal wear from cylinders, piston rings, gears, shafts, timing wheels, timing chains, valve tappets, guides, crankshaft, camshaft, rocker arm shaft, piston pins, roller bearings, and oil pumps.

Furthermore, preliminary XRF severity limits for Cu, Sn, Pb, and Al quantify running surfaces of connecting rod bearings, rocker arm shaft and piston pin bearings; and Si quantifies air intake dust. OES severity limits used here are accepted OES industry-standard alarm limits.

Figure 6. Cumulative distribution severity limits for Fe, Cr, Ni, Cu, Sn, and Al for this population. Click to enlarge.

Table 1 reports the preliminary severity limits for XRF based on cumulative distributions and reports within industry accepted limits for OES measurements:

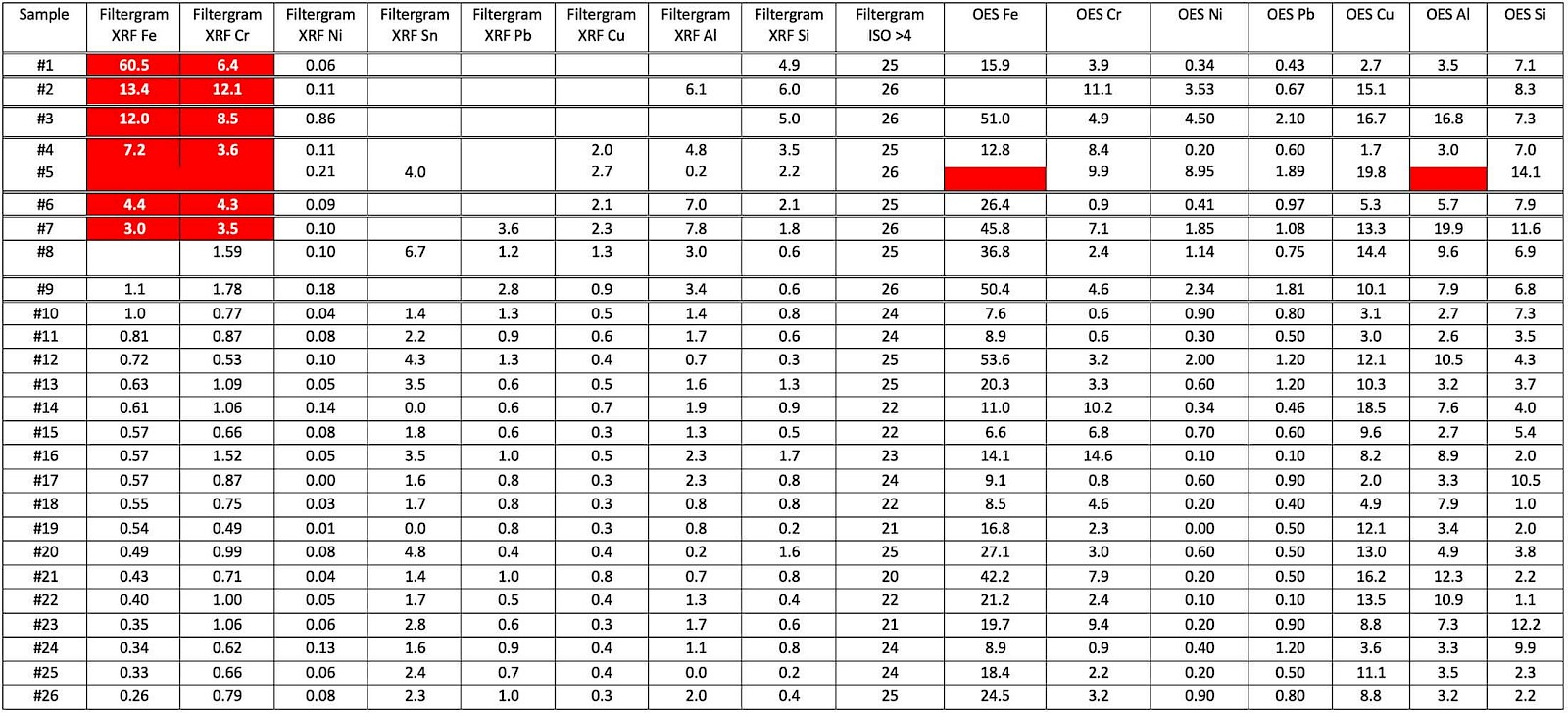

Table 2. Samples #1 to #26 reporting Filtergram XRF, ISO>4. Click to enlarge.

| Parameter | XRF (PPM) | OES (PPM) |

|---|---|---|

| Iron (Fe) | 2 | 60 |

| Nickel (Ni) | 0.5 | 11 |

| Chromium (Cr) | 2 | 31 |

| Copper (Cu) | 2 | 31 |

| Tin (Sn) | 6 | 10 |

| Lead (Pb) | 2 | 41 |

| Aluminum (Al) | 3 | 26 |

| Silicon (Si) | 11 | 41 |

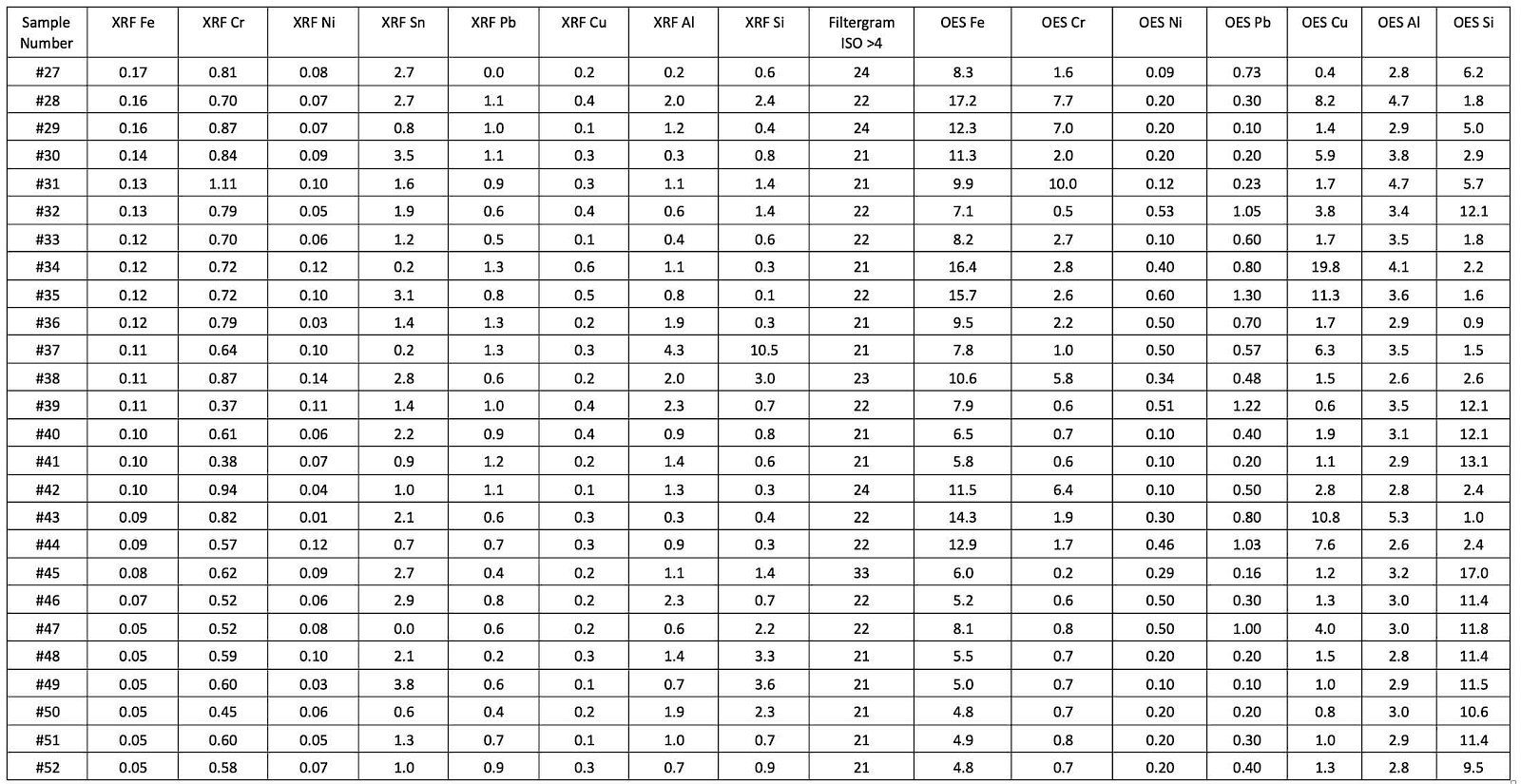

Alarming parameter values based on these limits are highlighted in Tables 1 and 2. Samples are numbered from #1 to #52, in order, based on largest to smallest XRF Fe measurement. Alarming wear-metal parameter values are shown highlighted for samples #1 to #9. There are not any alarming parameters for Samples #10 to #52.

XRF results show high severity ranking for samples #1 through #7 based on multiple ferrous alloy (Fe, Cr, and Ni) and nonferrous alloy (Cu, Pb, Sn, Al) parameters. Also, XRF shows high severity for sample # 8 based on Fe and is supported by elevated Cr. Finally, sample #9 has high severity based on Sn, supported by elevated Pb.

OES results show alarming Fe and Al for samples #2 and #5.

Table 3. Samples #27 to #52 reporting Filtergram XRF, ISO>4, and OES data. Click to enlarge.

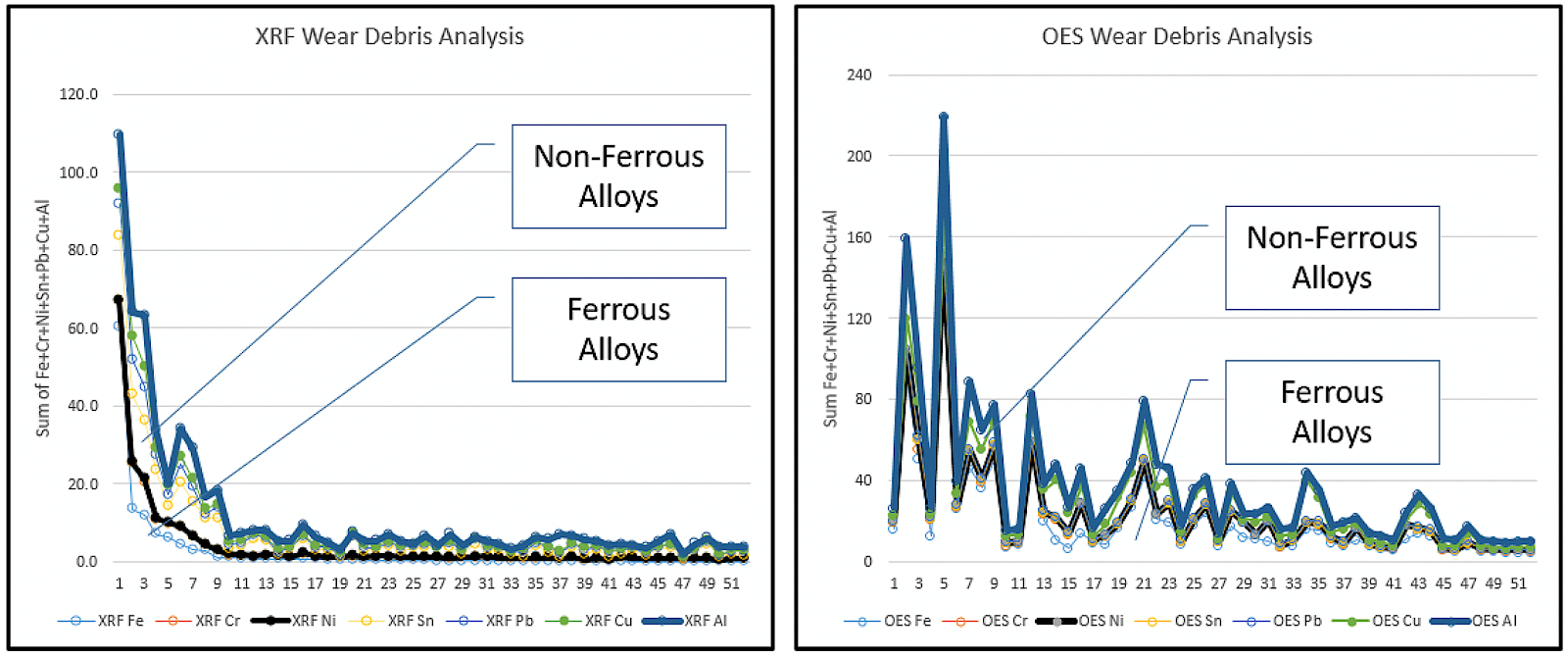

The graphs in Figure 7 sum up PPM measurements from Tables 2 and 3 and show ferrous and non-ferrous alloys for all samples #1 to #52.

The XRF graph on left shows PPM for > 4-micron wear debris accumulated on the filtergram. Samples #1 through #8 have severe ferrous alloys, samples #1, #2 and #3 have severe white and yellow soft-metal alloys, samples #4, #5, #6, #7 and #9 have severe, soft-white-metal alloys.

The OES graph on right shows PPM for < 4-micron dissolved substances and particulates. In this graph, samples #2 and #4 stand out having high Fe and Al, but the rest looks like noise.

A very important distinction to notice in Table 2 and Figure 5 is the capability to detect and quantify abnormal wear in soft metal alloys.

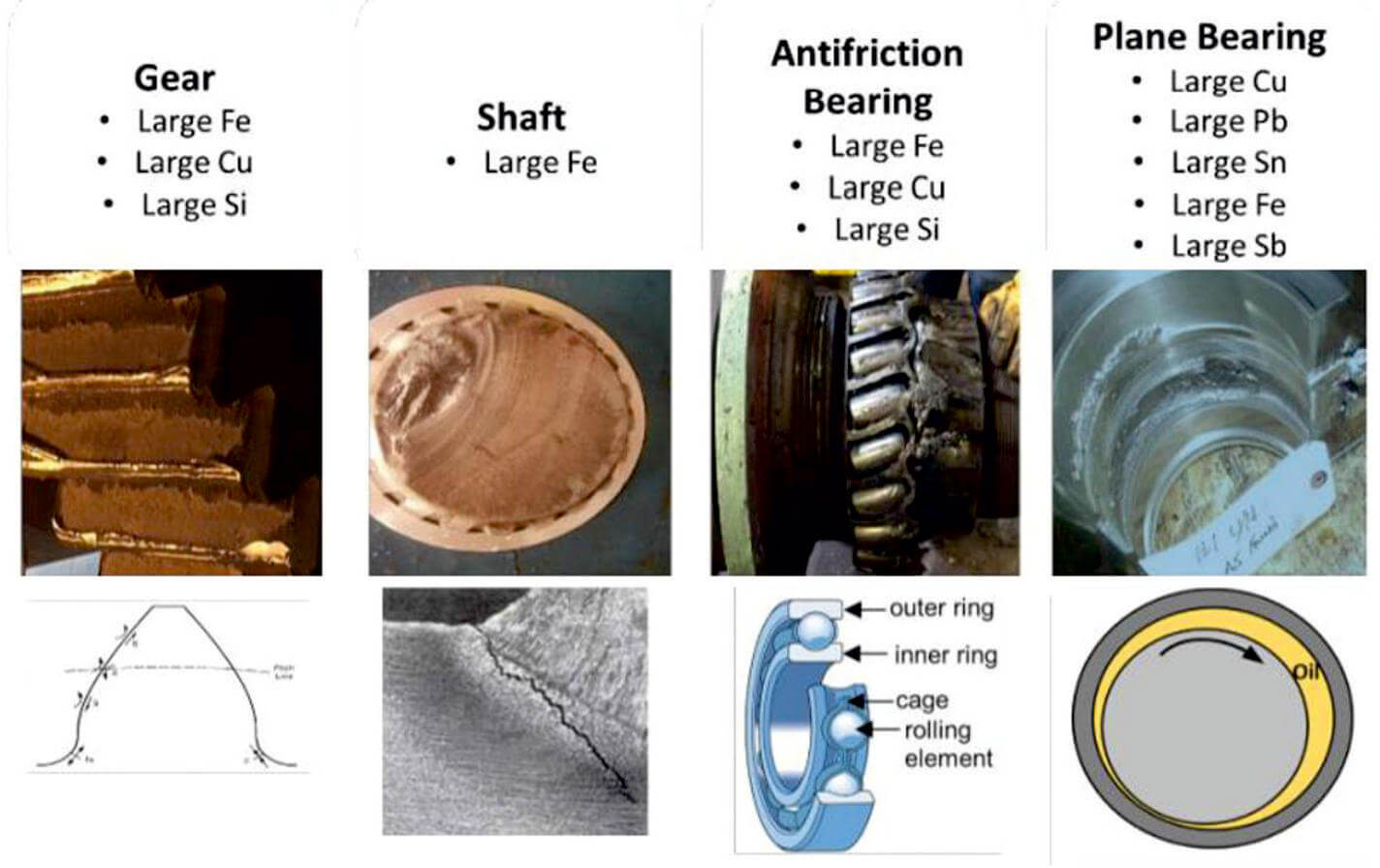

This table demonstrates multi-element large particle wear debris analysis. Figure 8 identifies crticical rotating machinery assets with similar needs to monitor ferrous alloy, white metal alloy, and yellow metal alloy components.

Root Cause Failure Analysis

Analytical Ferrography (AF), Filter Rotrode Spectroscopy (RFS), Scanning Electron Microscopy (SEM) and acid digestion are the standard methods for in-service oil analysis of ferrous and non-ferrous wear debris in the OES blind spot (> 4-micron to 2- millimeter range). Occasionally, one of these time-consuming methods is used with special justification, such as for root cause failure analysis (RFCA).

Filtergram specimens (see Figure 8) are retained and available for:

- Retest and comparison

- Microscopic wear debris analysis

- Future investigation

- Case history example, and

- Defect elimination

This article presents preliminary severity limits for ferrous and non-ferrous alloys metal components represented by a population of 52 diesel engine oil samples. Preliminary XRF severity limits for Fe, Cr, and Ni quantify abnormal wear from cylinders, piston rings, gears, shafts, timing wheels, timing chains, valve tappets, guides, crankshaft, camshaft, rocker arm shaft, piston pins, roller bearings, and oil pumps.

Furthermore, preliminary XRF severity limits for Cu, Sn, Pb, and Al quantify running surfaces of connecting rod bearings, rocker arm shaft and piston pin bearings, and Si quantifies air intake dust. Filtergram specimens may be retained and available for retest, future reference, defect elimination, and root cause failure analysis (RCFA).

Sources:

- Jim Fitch, “Copper and Your Diesel Engine Oils”, Practicing Oil Analysis, September 2004.

- Ray Garvey, “Severe Sliding and Fatigue Wear Debris Analysis for Machinery Components”, Spectro Scientific Blog, September 2022.

- Steffen Bots, “How to Set Elemental Limit Values for Motor Oils”, Machinery Lubrication, October 2015.