Predictive Maintenance vs Proactive Maintenance. Why Not Both?

Definitions:

Definitions:

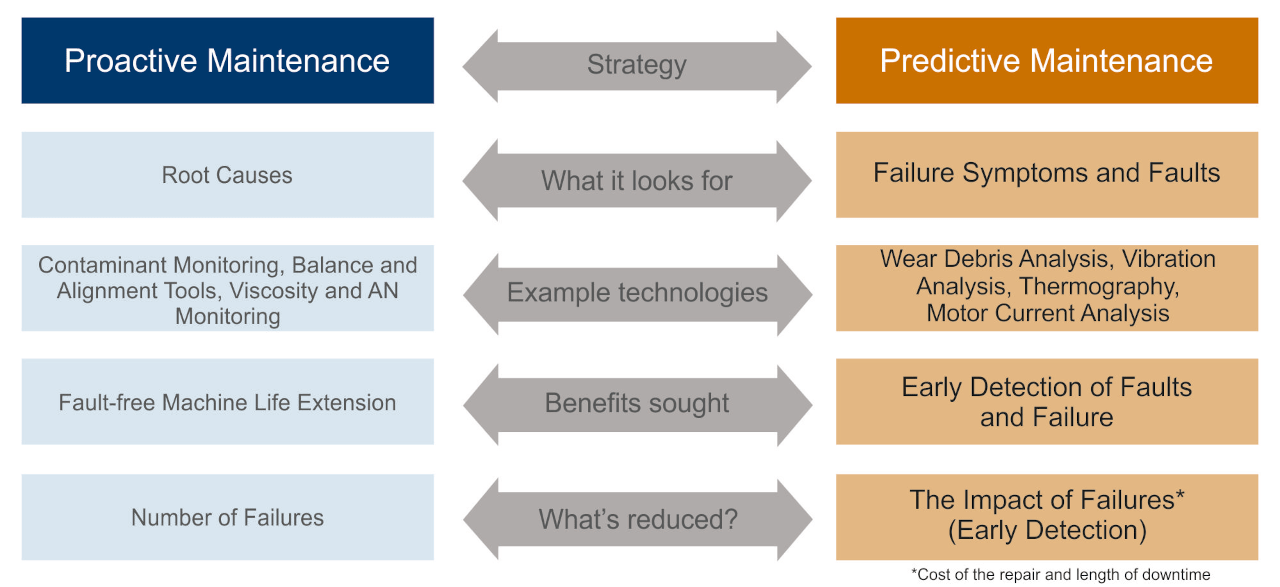

Proactive Maintenance - A type of condition-based maintenance emphasizing the routine detection and correction of root cause conditions that would otherwise lead to failure. Such root causes as high lubricant contamination, alignment and balance are among the most critical.

Predictive Maintenance - A type of condition-based maintenance emphasizing early prediction of failure using non-destructive techniques such as vibration analysis, thermography and wear debris analysis.

The efficient operation of industrial machinery hinges on two critical maintenance strategies: proactive maintenance and predictive maintenance. While both approaches fall under the broader umbrella of condition-based maintenance, their methodologies and impacts are distinct and complementary.

This article aims to demystify these concepts, clearly understanding how each strategy functions, their significance in the maintenance realm, and how they collectively represent a robust defense against machine failures and operational inefficiencies. We offer insights into optimizing maintenance practices for enhanced machine longevity and reliability by exploring their roles, benefits, and challenges.

Predictive Maintenance – Failure Detection (Early Signs)

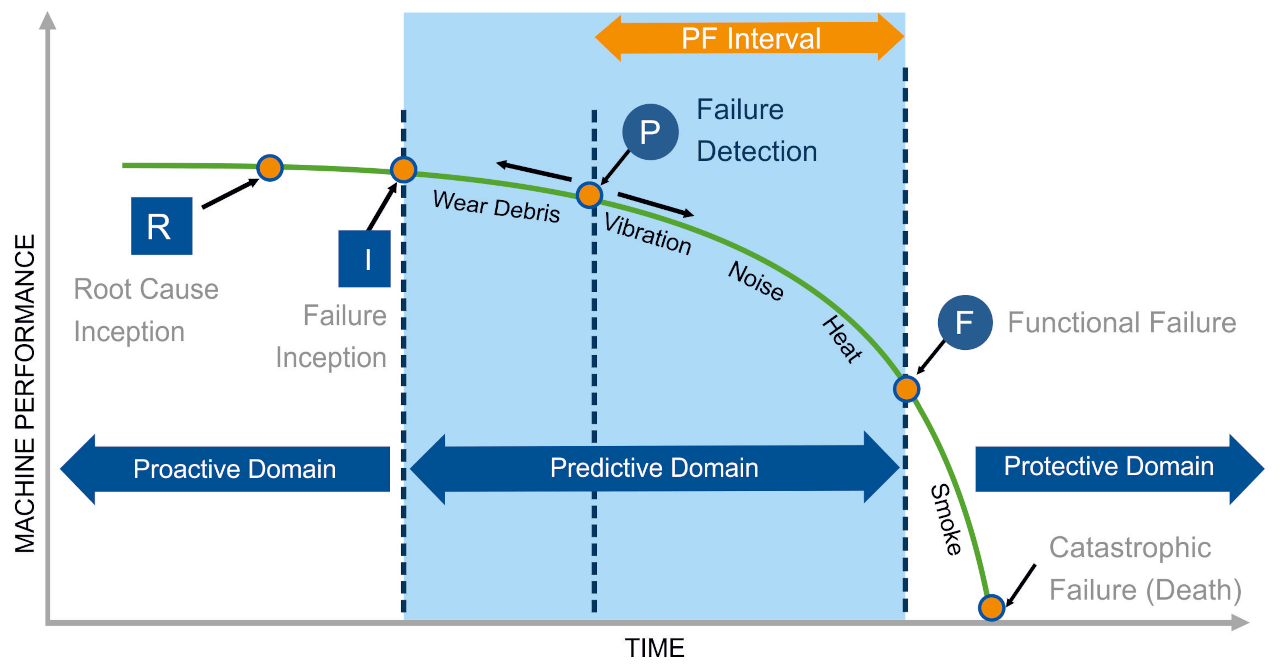

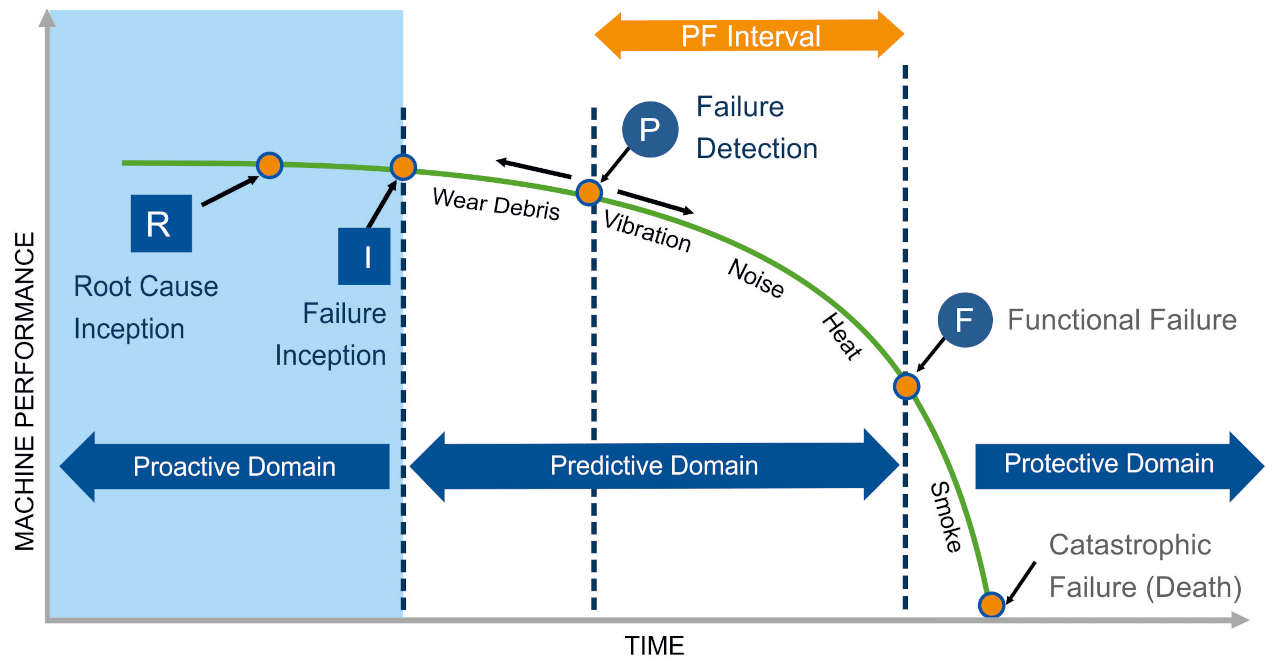

In the daily life of a typical lubricated machine, there can exist subtle wear that quietly mounts, unbeknownst to operators and maintenance teams. At the beginning of this failure mode, the Failure Inception (I) is practically imperceivable. But as it continues and the wear gradually progresses, the symptoms become measurable, and the point of Failure Detection (P) is reached.

With the right strategy that includes frequency condition monitoring, the closer failure detection is to failure inception. This is a crucial objective of predictive maintenance — to detect the signs of failure as early as possible.

Although, if failure is not properly detected, eventually the machine will experience enough wear and tear that it cannot perform work anymore, and the Functional Failure (F) point is reached, along with impact on production. The lack of detection could be due to a number of reasons, but most often due to infrequent monitoring, improper tools or lack of proper training. When gone unchecked, this is then followed by a Catastrophic Failure (Death), whereby the machine can seize up and produce collateral damage along the way.

The stages being described here are illustrated by the P-F Curve in the figure below. Traditionally, the P-F curve gets its namesake from monitoring conditions association to known failure modes between the detection of failure (P) and functional failure (F). Prediction of failure with early detection requires the right predictive maintenance strategy. Each failure mode may have a short or long P-F curve.

As the curve dips from left to right, the machine performance (y-axis) is negatively impacted. Machine failure gets more severe as time progresses (x-axis) and the symptoms of the machine failure are more easily detectable. But while this increased detection sounds like a good thing, unfortunately, this coincides with impending downtime and increased costs, as the damage is irreparable.

Proactive Maintenance – Pre-Failure Detection (Root Cause)

All machine failure is a consequence of the actions which preceded it. In other words, it’s what we do or don’t do in maintenance and operations that ultimately leads to the Failure Inception. This is where machine reliability is put to the test. De we rely on the robustness of the machine, or do we carefully set up our machines for success? Are we really doing what we can to delay the onset of failure as long as possible, at least to the point where the costs justify it?

The verdict from decades of studies from user groups, OEMs and research institutes on the most common reasons why bearings and other machine components fail, there is consensus that poor lubrication and insufficient contamination control are at the top of the list of root causes. Their introduction is marked by the point Root Cause Inception (R). The gap between the Root Cause Inception and the Failure Inception is a factor of root cause severity, component sensitivity and gestation time.

This is the crucial objective of proactive maintenance — to detect and correct the root cause conditions that would otherwise lead to failure.

Adoption of Condition-Based Maintenance Strategies

Predictive maintenance has become more commonplace in industrial facilities with the adoption of condition-monitoring technologies such as vibration analysis, thermography and wear debris monitoring. Particularly while real-time sensor technology and IoT infrastructure has accelerated the implementation. The best predictive-maintenance strategies are where incipient detection of failure is monitored.

When quick correction action is taken, it can minimize the impact failure has on costs of repair and the length of downtime.

Proactive maintenance has also experienced increased attention, with a focus on contamination-control strategies and monitoring contaminants and fluid properties with oil analysis. This is attributed, in part, to better education bringing to light the hidden impact contaminants and slight lubrication deficiencies have on machine reliability. When corrective action is taken within this domain, it reduces the number of failures and increases the life of the machines.

As such, the best strategies focus on condition monitoring as far to the left on the P-F curve as possible; this is where cost savings are greatest. But concurrently, this is challenged by the corrective action conundrum. When early detection of failure symptoms in the predictive domain occur, they are often questioned and the corrective action lacks because of a weak signal.

Such is often the case with early-stage wear debris detected with oil analysis. While effective in detecting this faint signal early, the machine appears to function otherwise normally, and corrective action may be delayed as more failure-mode confirmation is requested. But as the signal gets stronger and more obvious, so does the proximity to functional or catastrophic failure.

This becomes even more evident in the proactive domain where condition monitoring detects an issue with contamination or lubricant properties. Without a failure actually taking place (yet), questions are raised and action is deferred, despite even the relatively simple corrective actions such as filtration or lubricant changes.

All this can be addressed by proper education to bring awareness to proactive maintenance strategies as a cohesive complement to predictive maintenance, along with a little first-hand evidence.

In practice, both proactive maintenance and predictive maintenance can be performed side by side as a Condition-Based Maintenance Strategy, or CBM. It should not be assumed that proactive maintenance is the solution all by itself.

In fact, there are many root causes that will go unnoticed with typical proactive-maintenance approaches. Instead, it’s designed to tackle the 20% of root causes of failure responsible for 80% of the occurrences of failure (80:20 rule).

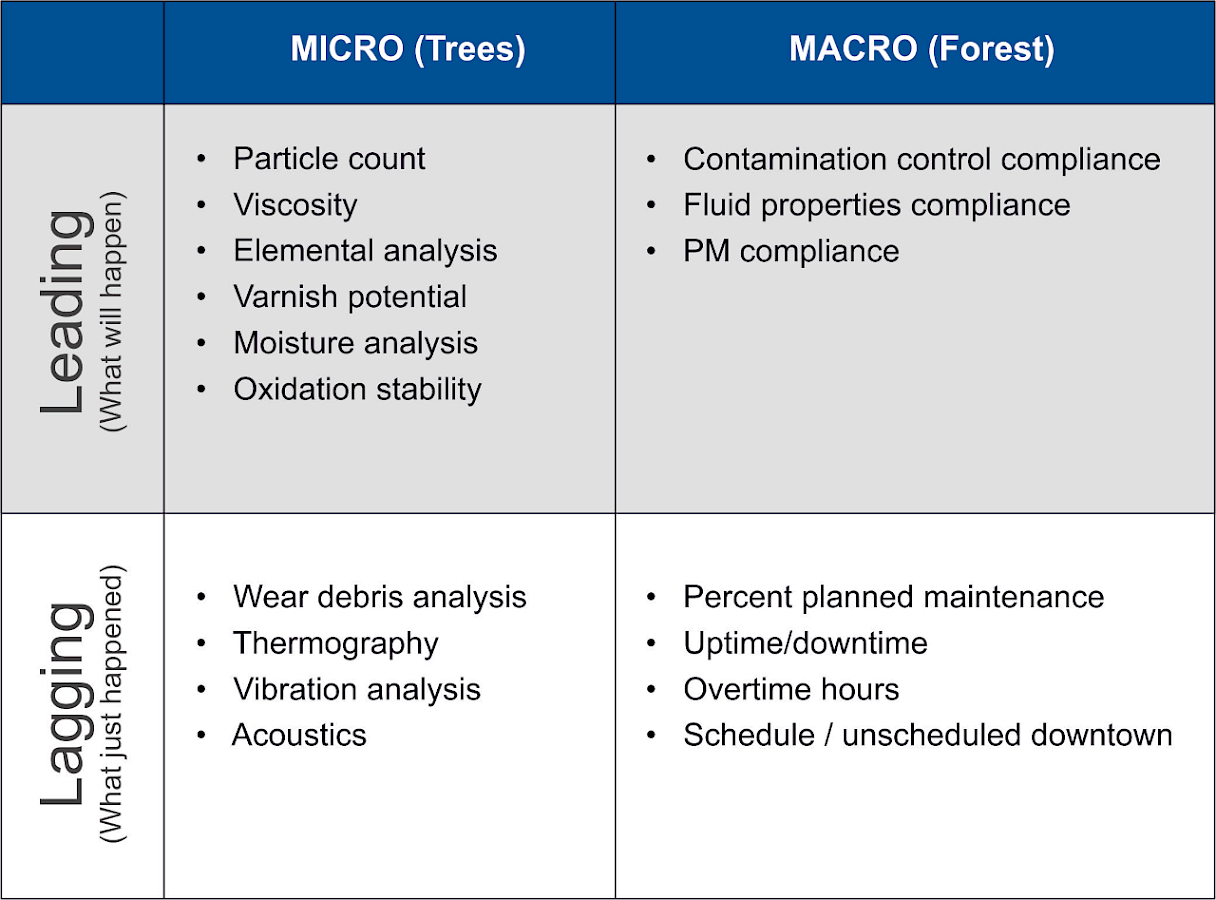

That said, predictive maintenance can help detect a majority of the remaining 20%. And since both proactive maintenance and predictive maintenance focus on the monitoring of conditions, they can be tracked with adjacent graphs and Key Performance Indicators (KPIs).

For individual machines, the proactive root cause conditions can be "leading indicators" (indicating what will happen) alongside the predictive-failure symptoms that can be considered the "lagging indicators" (indicating what just happened). Just the same way PM Compliance can be a leading indicator and scheduled/unscheduled downtime can be lagging indicators as a plant-wide KPI.

Empower your maintenance strategy with the cutting-edge insights and solutions from Noria Corporation. Whether you're looking to implement proactive or predictive maintenance practices, our team of experts is ready to guide you through every step. Visit Noria to discover a wealth of resources, training programs, and consulting services tailored to elevate your maintenance operations. Let us help you transform your approach to machine reliability and efficiency — start your journey today!