The Critical Role of Viscosity Index in Lubrication

Understanding the importance of each property of a lubricant is more than just about the lubricant — it's a critical factor in ensuring the longevity and efficient operations of industrial machines. At the heart of these properties lies viscosity, perhaps the most important physical property of a lubricant, whether it be an oil or a grease.

Understanding the importance of each property of a lubricant is more than just about the lubricant — it's a critical factor in ensuring the longevity and efficient operations of industrial machines. At the heart of these properties lies viscosity, perhaps the most important physical property of a lubricant, whether it be an oil or a grease.

This article reviews the viscometrics of a lubricant, particularly the crucial role of Viscosity Index (VI) in lubricant selection.

Viscosity: The Cornerstone of Lubrication

Viscosity, in its simplest definition, is a measure of a lubricant's resistance to flow, but often analogized as the 'thickness' or ‘thinness’ of the oil. This very property is what forms the hydrodynamic wedge, or film thickness, that separates machine surfaces — a critical layer that prevents the direct contact of moving metal surfaces within nearly every machine in our industry.

Without it, machine wear would occur almost instantly. When put like that, it’s clear why it is treated with such importance, right? Ok, let’s move on.

The efficiency of this film thickness is largely contingent on the viscosity of the lubricant. However, viscosity is not a static attribute; it's a dynamic property heavily influenced by a range of factors. Temperature also plays a familiar role in dictating viscosity.

Generally, an oil's viscosity increases (or thickens) as temperatures decrease. And conversely the viscosity decreases (or gets thinner) at higher temperatures. This variable nature of viscosity with temperature fluctuations brings us to a fundamental aspect of lubricants — the Viscosity Index.

The Viscosity Index Explained

The Viscosity Index (VI) is a measure that defines how the viscosity of an oil changes with respect to a change in temperature. Understanding VI is crucial to discern whether a lubricant meets the operational requirements of machinery across various temperature ranges. It's not merely a technical specification; it’s a compass guiding the selection of the right lubricant for effective machinery maintenance.

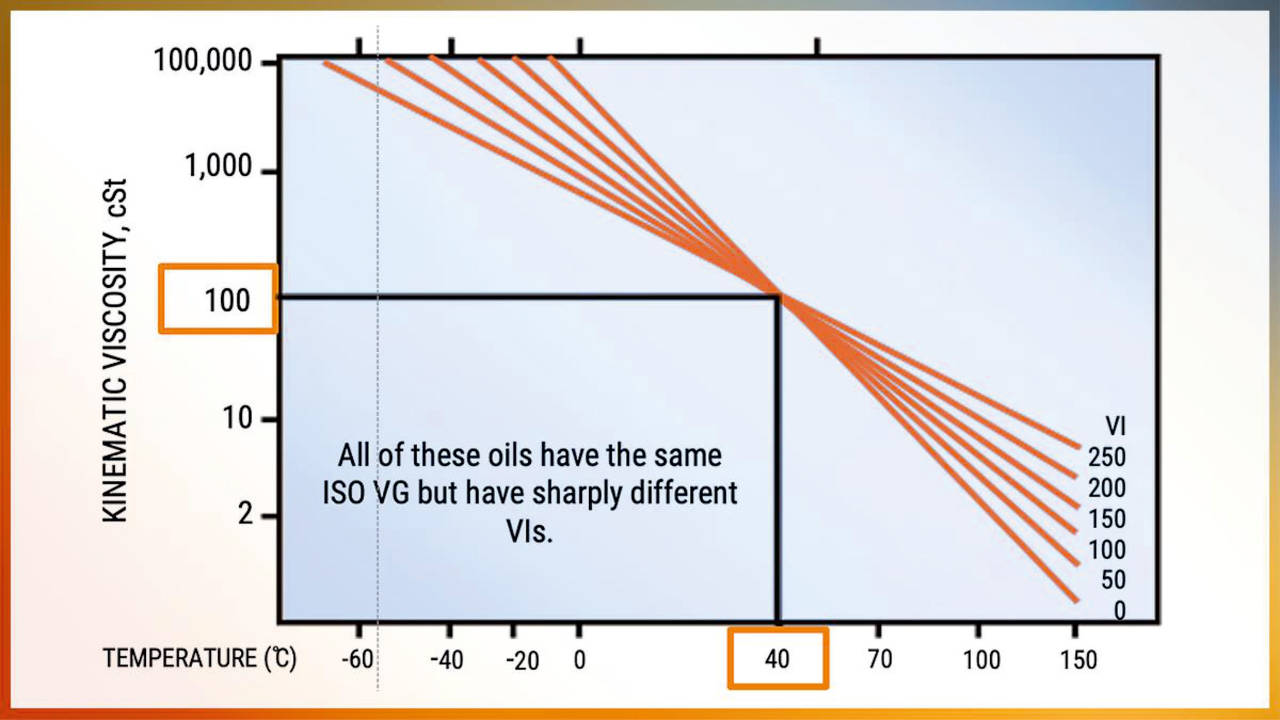

The VI of an oil is determined by measuring its viscosity at two standard temperatures: 40°C and 100°C. These values are then compared against a scale derived from two reference oils. Conventional mineral oils typically have a VI ranging between 95 to 100, while highly refined mineral oils stand around 120.

Synthetic oils, known for their superior qualities, can have a VI up to 250 or more. This is a unitless number, but simply put: a higher VI is more desirable as this indicates a lower rate of viscosity change with temperature fluctuations.

This concept can be visualized through a graph with viscosity on the vertical axis and temperature on the horizontal axis. Oils with higher VIs exhibit a more horizontal slope, indicating their ability to maintain a stable lubricating film over a wider temperature range.

The Impact of Viscosity Index on Different Machinery

Different types of machinery, such as gearboxes, compressors, crankcase engines, and hydraulics, each come with their own set of lubrication needs. These needs are heavily influenced by the machinery's design, operational loads, and speed, which in turn dictate the required viscosity — and by extension, the Viscosity Index — of the lubricant.

In gearboxes or compressors, for instance, the right VI is imperative to ensure that the lubricant maintains an adequate film thickness under varying operational temperatures and loads. If operating temperature were to decrease such as during down periods or cold weather conditions, the viscosity would get too thick which would lead to several issues, including increased energy consumption with higher fluid friction or restricted oil circulation.

If operating temperatures get too high, then the resulting decrease in viscosity would lead to rapid mechanical wear. Both scenarios result in subsequent failure. Both scenarios are mitigated by a higher VI that is properly selected.

It's clear that high VIs are particularly crucial in machines that experience wide temperature variations. For example, a lubricant in an outdoor compressor during a cold morning might face drastically different conditions by midday as temperatures rise. A lubricant with a high VI will fluctuate less in terms of viscosity, providing more consistent protection throughout these temperature changes.

Yet, the VI's role goes beyond just managing temperature-induced viscosity variations. It's about ensuring that the lubricant can effectively support the machinery's specific design and operational demands. The ideal lubricant forms a film robust enough to prevent metal-to-metal contact, yet fluid enough to allow for efficient movement of parts.

Viscosity Index Improvers

The science behind lubrication has evolved to meet the diverse and demanding needs of modern machinery over the decades, leading to the development of Viscosity Index Improvers (VII). These are additives designed to enhance a lubricant's VI, enabling it to operate efficiently over a broader temperature range.

VII are typically polymers added to oil to minimize the rate of viscosity change with temperature (thus increasing the VI). They essentially work by expanding as they heat up, which counteracts the oil's natural tendency to thin at higher temperatures. The use of VIIs is a balancing act — while they offer the advantage of broadening the temperature range over which the oil can operate effectively, they can also introduce complexities.

One of the challenges with VI improvers is that they can be sheared down in service, particularly in high-stress environments like gearboxes or engines. This shearing can lead to a permanent loss of viscosity, and by extension, a decrease in the lubricant’s effectiveness.

It's a phenomenon known as Temporary Viscosity Loss (TVL), and it's a critical factor to consider when selecting a lubricant with VI improvers, especially for high-shear applications. With minerals oils often requiring more VII, these scenarios are benefited from the use of synthetics that have a naturally higher VI.

Despite these limitations, the benefits of VII are undeniable, particularly for equipment operating across a wide range of temperatures. The key is in choosing a lubricant with the right balance of VI improvers to meet the specific needs of the machinery without introducing undue risk of shear-induced viscosity loss.

Best Practices in Viscosity Index Selection

Selecting the right VI for a lubricant is as much an art as it is a science. It requires a deep understanding of the machinery's operational parameters and environmental conditions. Here are some best practices to guide this selection process:

-

Know Your Machinery’s Requirements – Each piece of machinery has its unique viscosity needs based on its design, operational speeds, and loads. Understanding these requirements is the first step in selecting a lubricant with the appropriate VI. For instance, bearings in high-speed machinery may need a lower viscosity oil compared to those in heavy-load, slow-speed gear systems. Lower viscosity oils can be more impacted by small changes in VI, this it’s more critical to get right.

-

Consider the Operating Environment – It should come as no surprise at this point that ambient temperature and temperature variations play a significant role in VI selection. Machinery operating outdoors in variable climates will benefit from lubricants with a higher VI compared to those used in more controlled environments.

-

Balance VI with Other Lubricant Properties – While VI is crucial, it's not the only property to consider. Balancing VI with other lubricant characteristics, such as base-oil type, additive composition, and wear protection capabilities, is essential for optimal lubricant performance.

A Case Example in VI Selection

Let's consider the case of a large industrial gearbox operating in a fluctuating climate. During winter, temperatures plummet and cause the lubricant to thicken, which could lead to insufficient lubrication at startup. Conversely, in the summer heat, the same lubricant might become too thin and fail to maintain an adequate lubricating film.

The maintenance team initially used a conventional mineral oil with a moderate VI. However, they noticed increased wear during seasonal temperature changes, leading to frequent maintenance and costly downtime.

The solution came with the switch to a synthetic lubricant with a higher VI and VI improvers. This change resulted in a more stable viscosity across temperature variations, reducing wear and extending the gearbox's service life. This is a common example that underscores the importance of VI in lubricant selection and its direct impact on machinery reliability and maintenance costs.

Viscosity Index Calculator

In the digital era, where information is at our fingertips, having practical tools to apply theoretical knowledge is invaluable. An interactive Viscosity Index calculator, which is currently under development at Noria, precisely serves this purpose.

The VI calculator is straightforward to use. Simply input the oil’s viscosity at 40°C and 100°C, and the calculator will estimate its VI. This tool not only aids in understanding the VI of a current lubricant but also assists in comparing potential alternatives. You can also input a known VI and viscosity at one of the temperature points to calculate the viscosity at the other temperature point.

Example Calculation: Let's say you have an oil with a viscosity of 100 cSt at 40°C and 15 cSt at 100°C. Inputting these values into the calculator will yield a VI or 157. This is higher than mineral oil and is likely a synthetic. This calculation should help in understanding how this oil will behave across various temperature changes, particularly when assessing whether it is suitable for your specific machinery and operating conditions.

Final Note

The Viscosity Index is more than just a number on a lubricant’s data sheet — it's a critical factor in ensuring the health and efficiency of your machinery. Understanding and utilizing VI in lubricant selection can significantly improve machinery performance, reduce maintenance costs, and extend equipment life. Whether you are a seasoned maintenance professional or new to the world of industrial lubrication, acknowledging the critical role of VI will undoubtedly enhance your approach to machinery maintenance.

Staying informed and utilizing tools like the VI calculator is an essential part of lubricant selection. It can help ensure that your machinery continues to operate at its peak, regardless of the challenges posed by varying temperatures and operational demands.

If you have any questions at all about how this calculator can be used or other variations with your specific application, please don’t hesitate to contact Noria. Remember, the right lubricant, with the appropriate VI, is not just a commodity: it's a vital component of your machinery's health and your operation's success.